Method of knitting stripe pattern of tubular knitting fabric and the knitting fabric

A technique of knitted fabrics, stripes, applied in the direction of knitting, weft knitting, textiles and papermaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

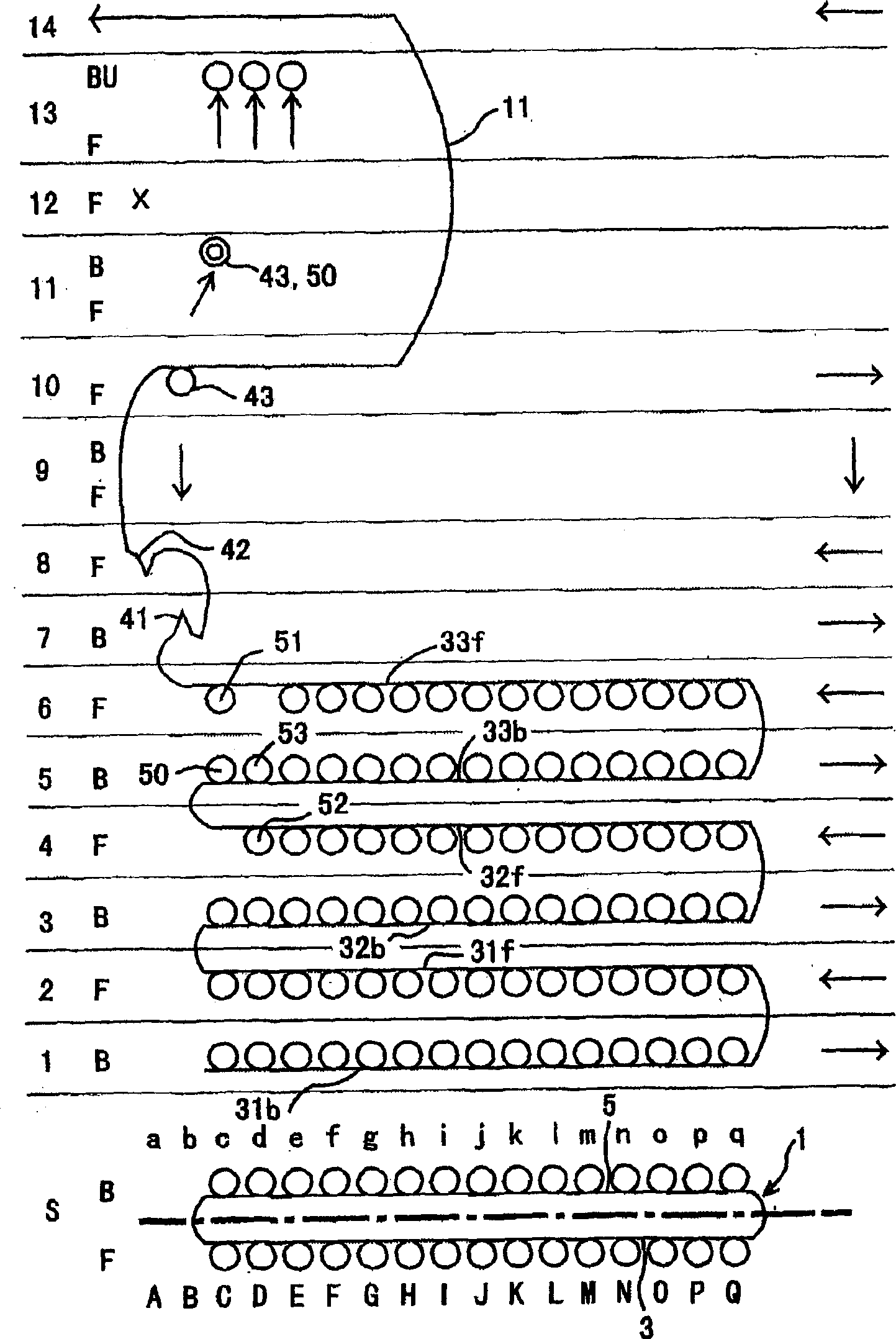

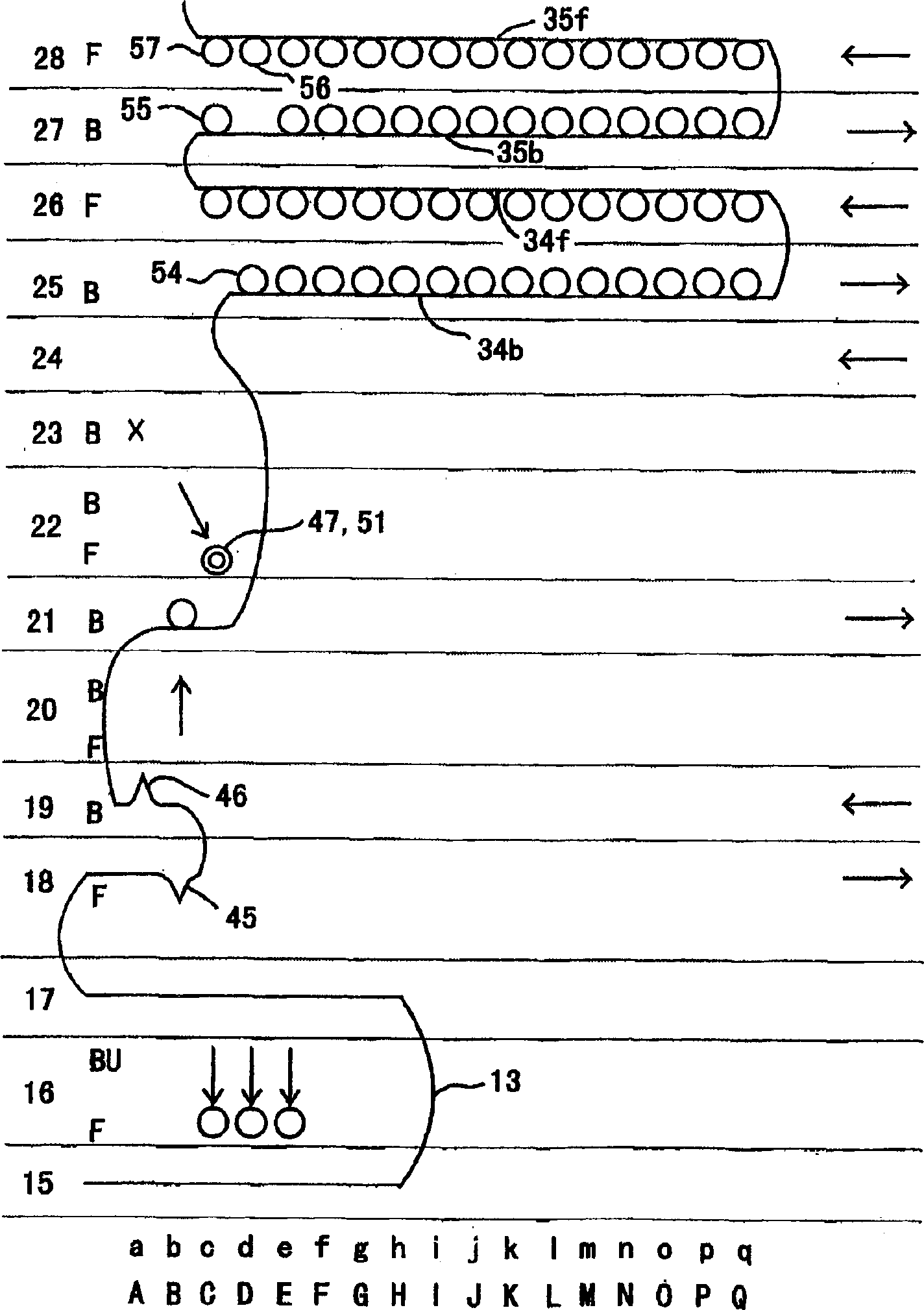

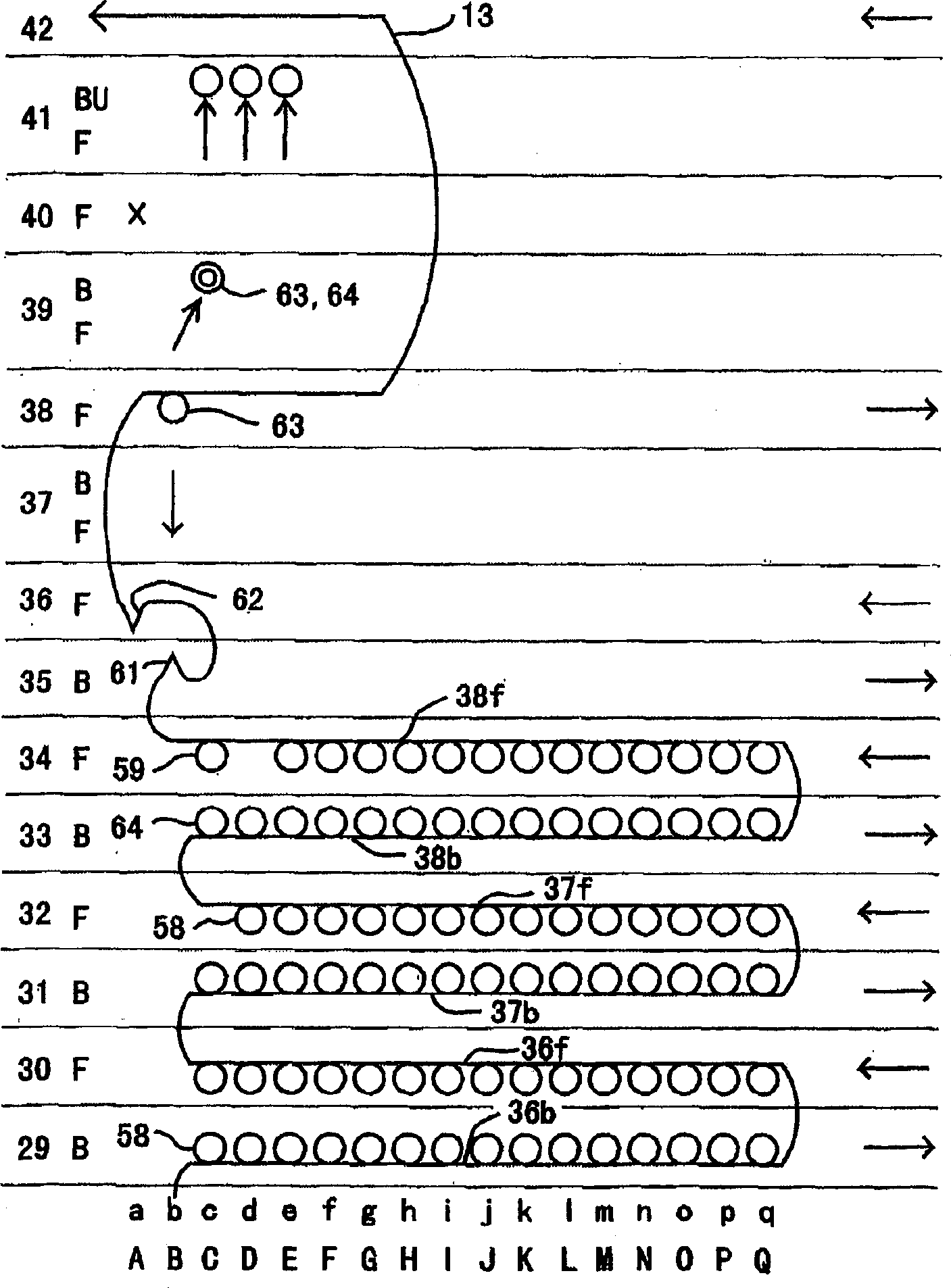

[0036] As a preferred embodiment of the present invention, the two-color stripe formed by the tubular first and second knitted fabric parts is taken as an example and described as follows together with the accompanying drawings. Figure 1 ~ Figure 3 The knitting procedure of the plain knit tubular knitted fabric incorporating the stripes knitted in this embodiment is shown. The left and right arrows in the figure indicate the moving direction of the yarn feeding member, and the up and down arrows indicate the transfer direction. F represents the front needle bed, B represents the rear needle bed, A to Q represent the knitting needles of the front needle bed, and a to q represent the knitting needles of the rear needle bed. The front knitted fabric 3 constituting the tubular knitted fabric 1 is knitted by the needles of the front needle bed; the rear knitted fabric 5 is knitted by the needles of the rear needle bed. Figure 4 The stitch structure in the vicinity of the knittin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com