Passenger vehicle body structure torsion rigid test restraining and loading device

A loading device and torsional stiffness technology, which is applied in the testing of machines/structural components, measuring devices, and vehicle testing, can solve problems such as the high price of general-purpose hydraulic force devices, the influence of restraint devices and the stiffness of loading devices, etc., and meet the requirements of The effect of test accuracy and reliability, cost reduction, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

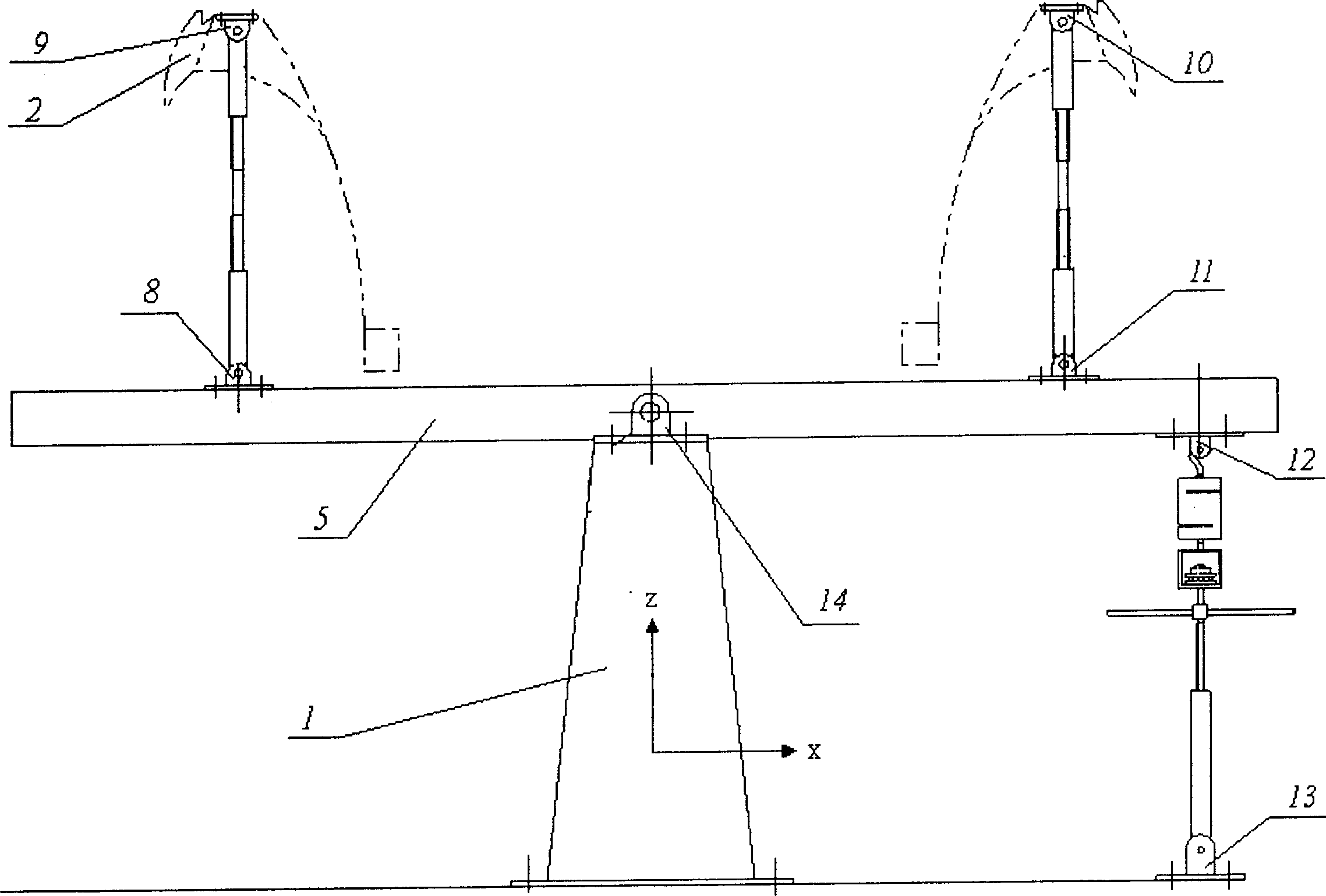

[0027] The device comprises two parts, a restraint device and a loading device fixed on the workbench. The specific structure and preferred mode of the present invention are further described below in conjunction with the accompanying drawings:

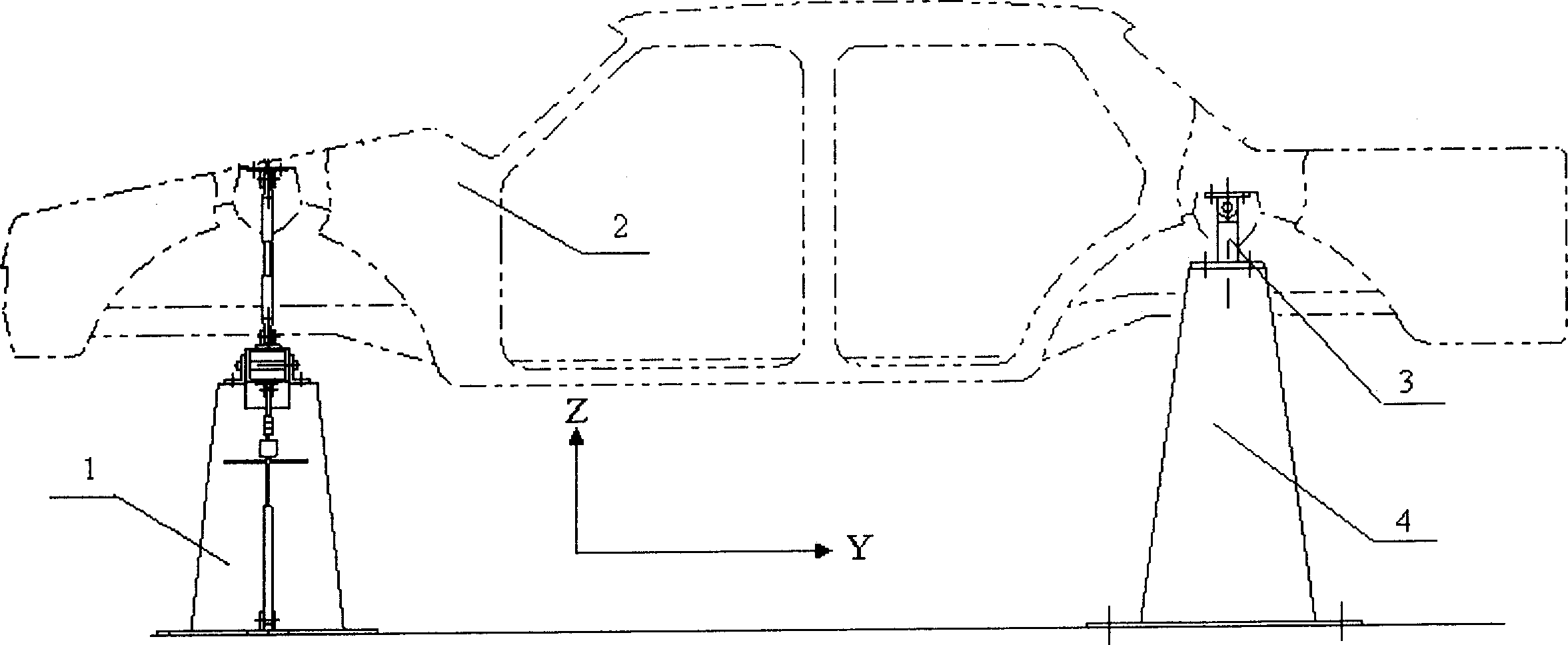

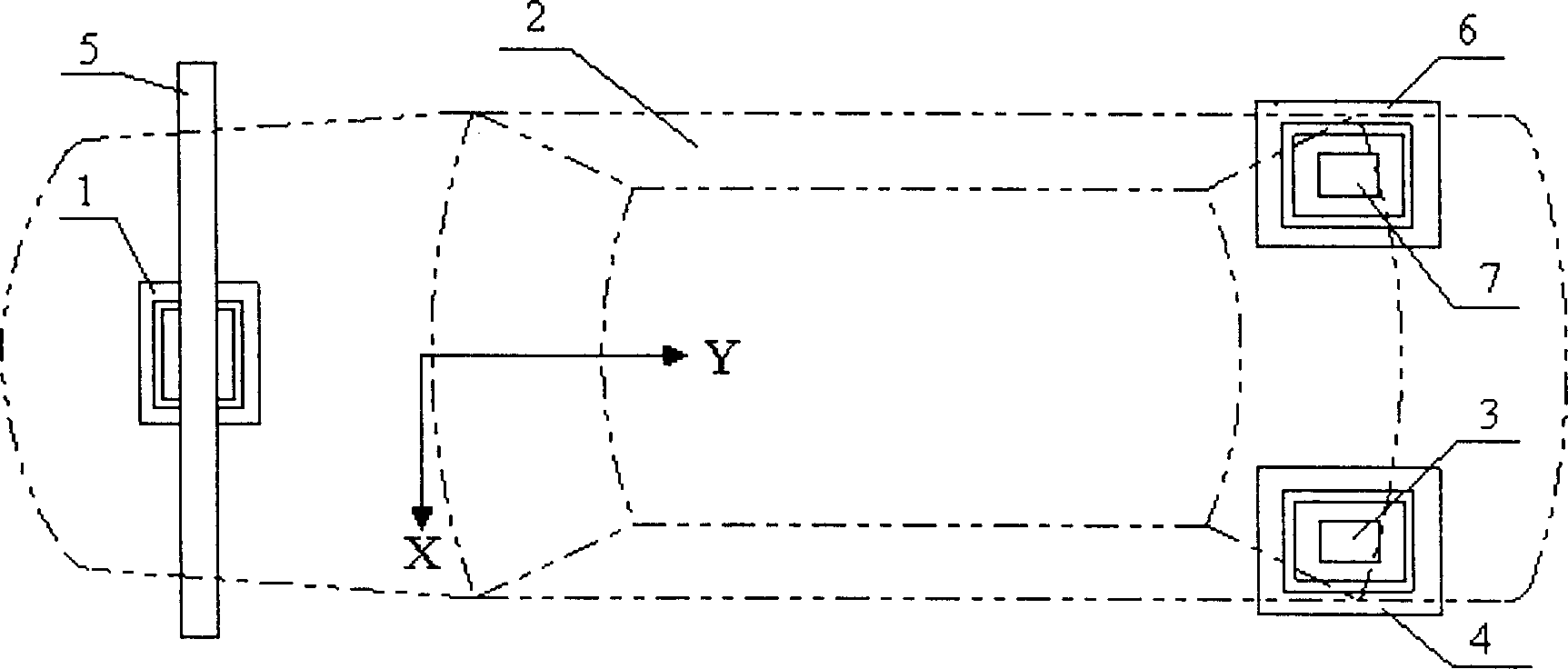

[0028] 1. Constraint device: such as figure 1 , figure 2 Shown, this device is made up of left and right rear support 4,6 and connecting part 3,7. On the left and right rear suspensions on the vehicle body, the support position (the connecting surface of the suspension top and the vehicle body) is connected with the bearing by the connecting part, and the connecting parts 3, 7 can adopt the hinge that only allows the vehicle body to rotate around the X axis passing through the connecting point. The left and right rear supports 4 and 6 are fixed on the T-shaped worktable whose fixed position can be adjusted, and can adapt to different vehicles by adjusting the fixed positions of the left and right rear supports.

[0029] 2. Loading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com