Composite elastic soft sealing

A soft-sealing, composite technology, applied in the direction of lift valve, cock including cut-off device, engine components, etc., can solve the problems of easy falling off, difficult connection between sealing rubber and valve seat, etc., to achieve firm adhesion, simple structure, processing and installation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

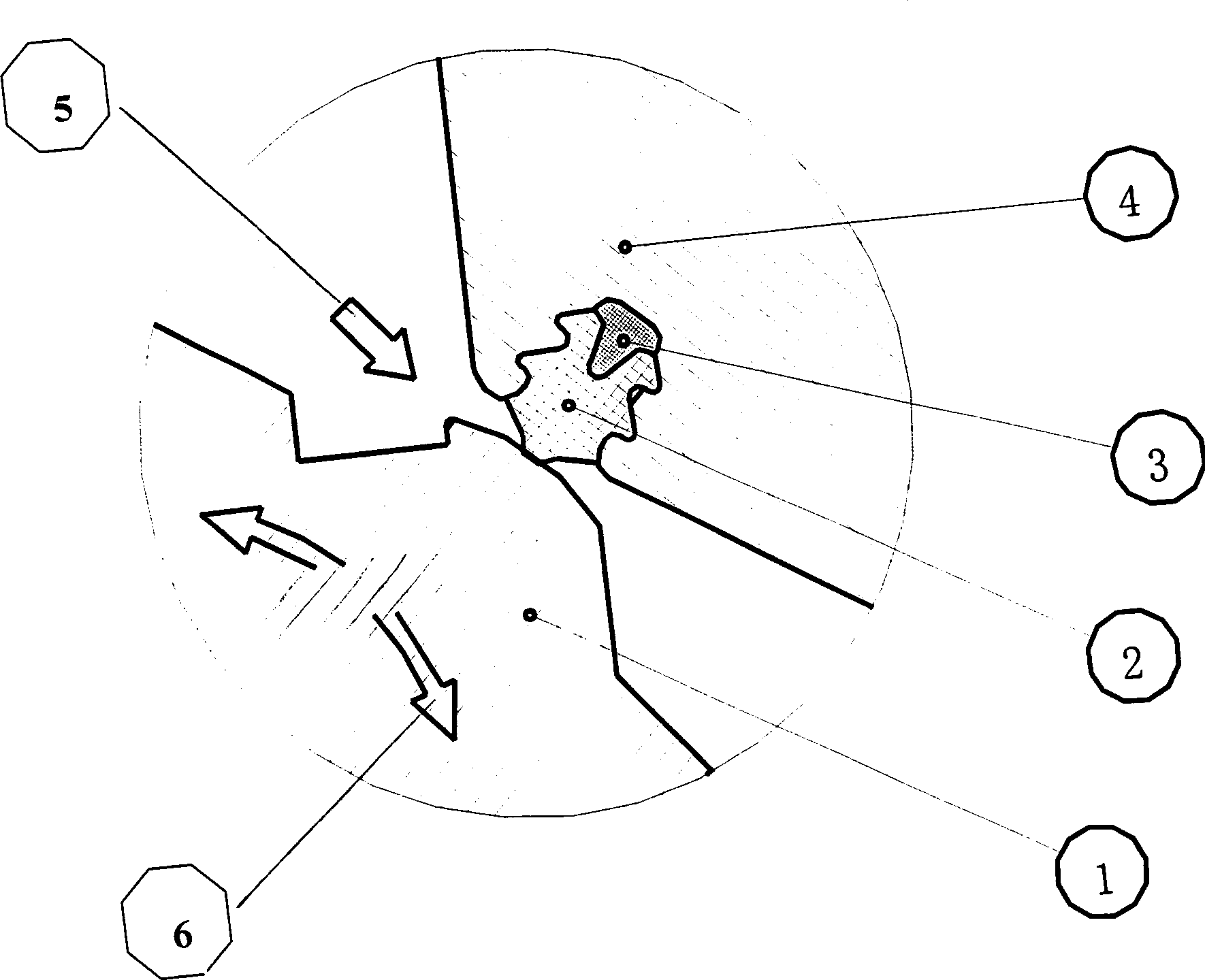

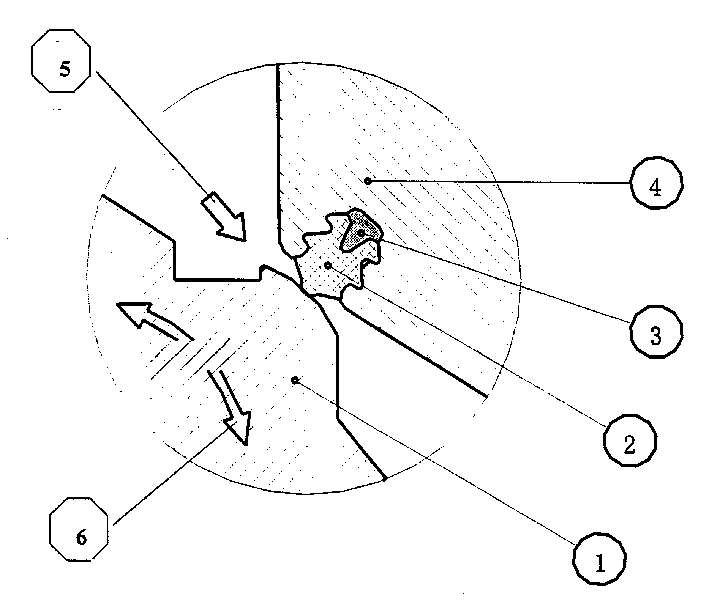

[0017] like figure 1 As shown in the figure, the composite elastic soft seal of the present invention is composed of a valve flap sealing ring 1 and a valve seat sealing ring 2. The valve seat sealing ring 2 is embedded in the valve seat 4, and the valve seat 4 has a tooth-shaped groove. After the sealing ring 2 is embedded in the valve seat 4, silicone rubber (ie, the sealing ring gasket 3) is injected. That is to say, the sealing ring is a double-layer composite structure, which is composed of a valve seat sealing ring 2 and a sealing ring gasket 3, and the sealing ring gasket 3 is injected and cured in a glue-like manner after the sealing ring 2 is installed. The valve seat sealing ring 2 and the valve seat 4 are connected in a toothed mosaic manner. Relying on the resilience of the valve seat sealing ring 2 to ensure the sealing, the specific pressure between the valve disc sealing ring 1 and the valve seat sealing ring 2 is increased, and the sealing performance is impro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com