Method for detecting production line of communication product single board with CPU

A central processing unit and production line technology, applied in the field of communication, can solve problems such as large differences in test operations, unfavorable mastery and use, and lack of standardized solutions and design guidelines, etc., to achieve the effect of easy mastery and operation, and standardized test procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

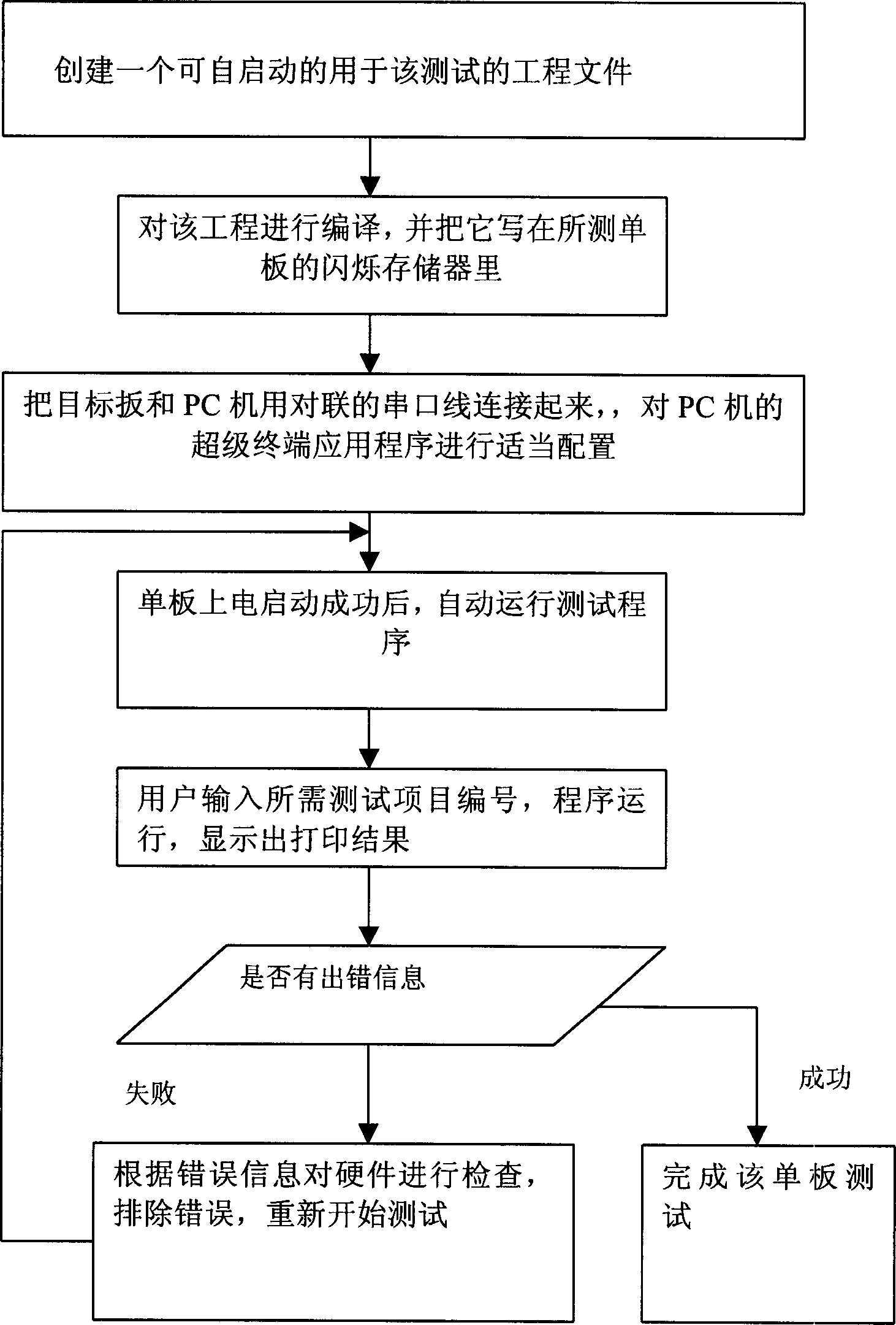

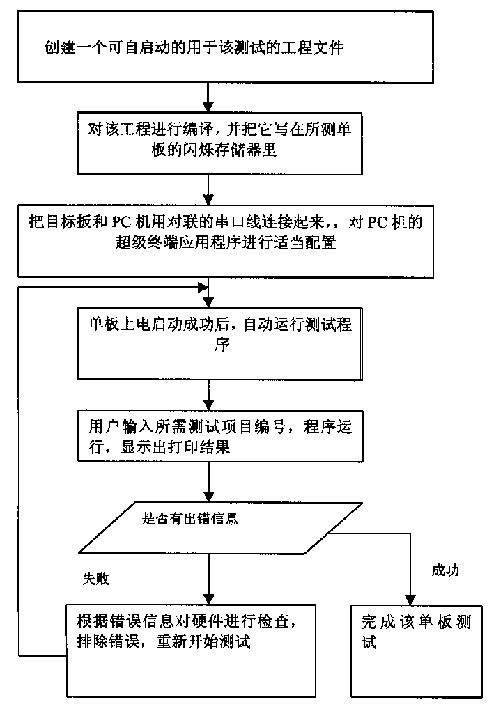

[0018] figure 1 It is a flow chart of the method of the present invention.

[0019] First create a self-starting project file for the test, so that the test program will be automatically executed after the board is powered on;

[0020] Then compile the project and write it in the flash memory of the single board under test;

[0021] Then connect the single board under test and the test PC host machine with the serial port line of the couplet, the monitor of the PC machine is used as the display terminal, and the keyboard is used as the input terminal, open the super terminal application program of the PC machine, and configure it appropriately;

[0022] Then power on the board under test. After the single board under test starts successfully, the test program will run automatically; the screen will output the test program interface and display the user input prompt;

[0023] Then the user inputs the required test item number, the program runs, and the print result is displa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com