Testing apparatus for fully automatically controlling aggregate solidity and testing method

A test device and firmness technology, which is applied in the field of fully automatic control aggregate firmness test equipment, can solve the problems of easy interruption of the test, weak integrity, complicated test process, etc. The overall effect of the test is strong

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

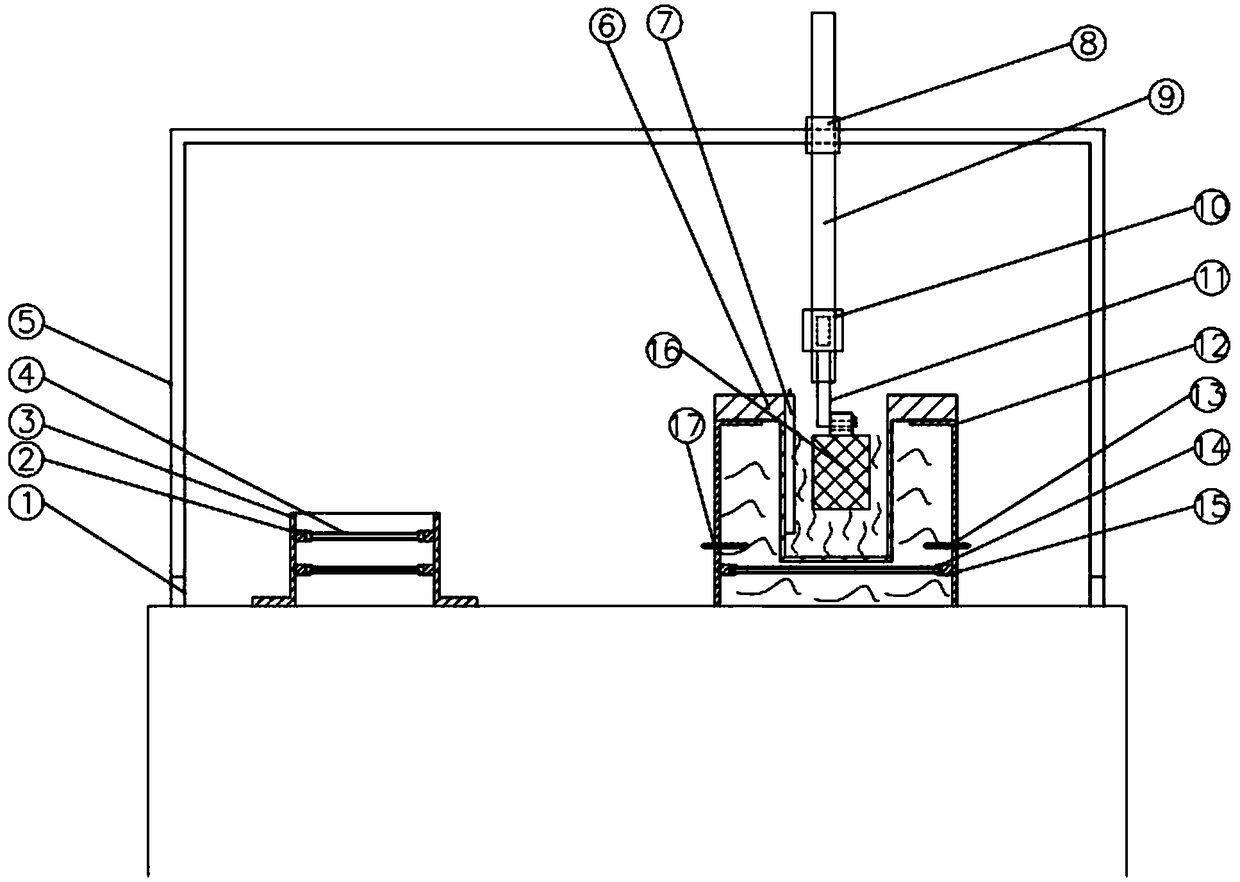

[0027] The following is attached figure 1 The structure of the present invention and its beneficial effects are further described.

[0028] Such as figure 1 The fully automatic control aggregate solidity test device includes a test worktable, a control system, a manipulator operating device, a drying device, a constant temperature water tank 12 and a soaking device;

[0029] Both the drying device and the constant temperature water tank 12 are arranged on the center line of the test workbench, and the two are arranged linearly. The linear arrangement can effectively reduce the distance between the drying device and the constant temperature water tank 12, and is convenient for manipulators to operate the device. Move through the gantry slide 5;

[0030] The control system mainly includes an operation interface, electrical control circuit, temperature control instrument and control box, wherein the operation interface is arranged in front of the constant temperature water tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com