Large-sized concrete cylindrical structure whose wall end possesses excavating device and sinking method

A concrete and cylinder technology, which is applied in basic structure engineering, construction, sheet pile wall and other directions, can solve the problems of difficult control and adjustment of offset, limited depth of subsidence of cylinder structure, large amount of engineering, etc., and achieves construction operation. Simple, guaranteed tilt accuracy, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

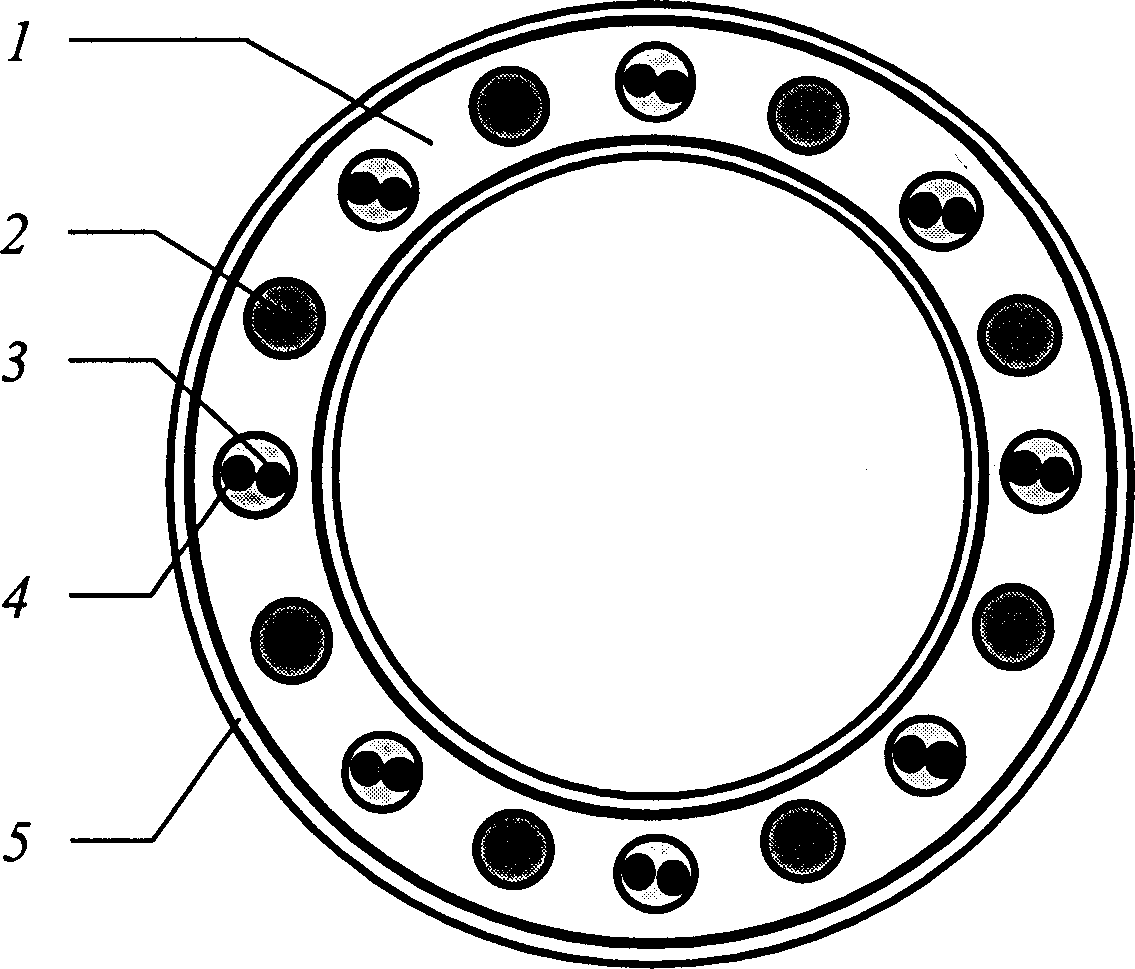

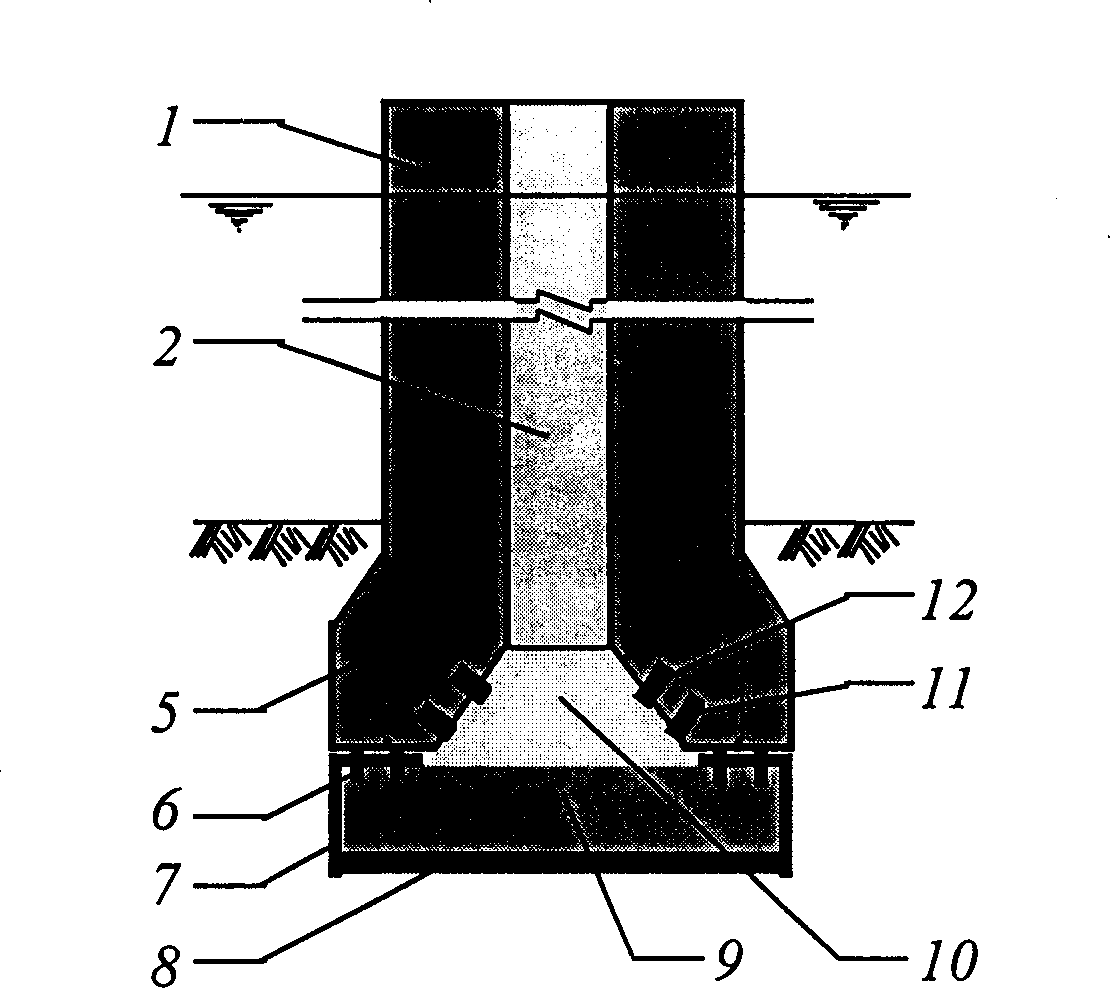

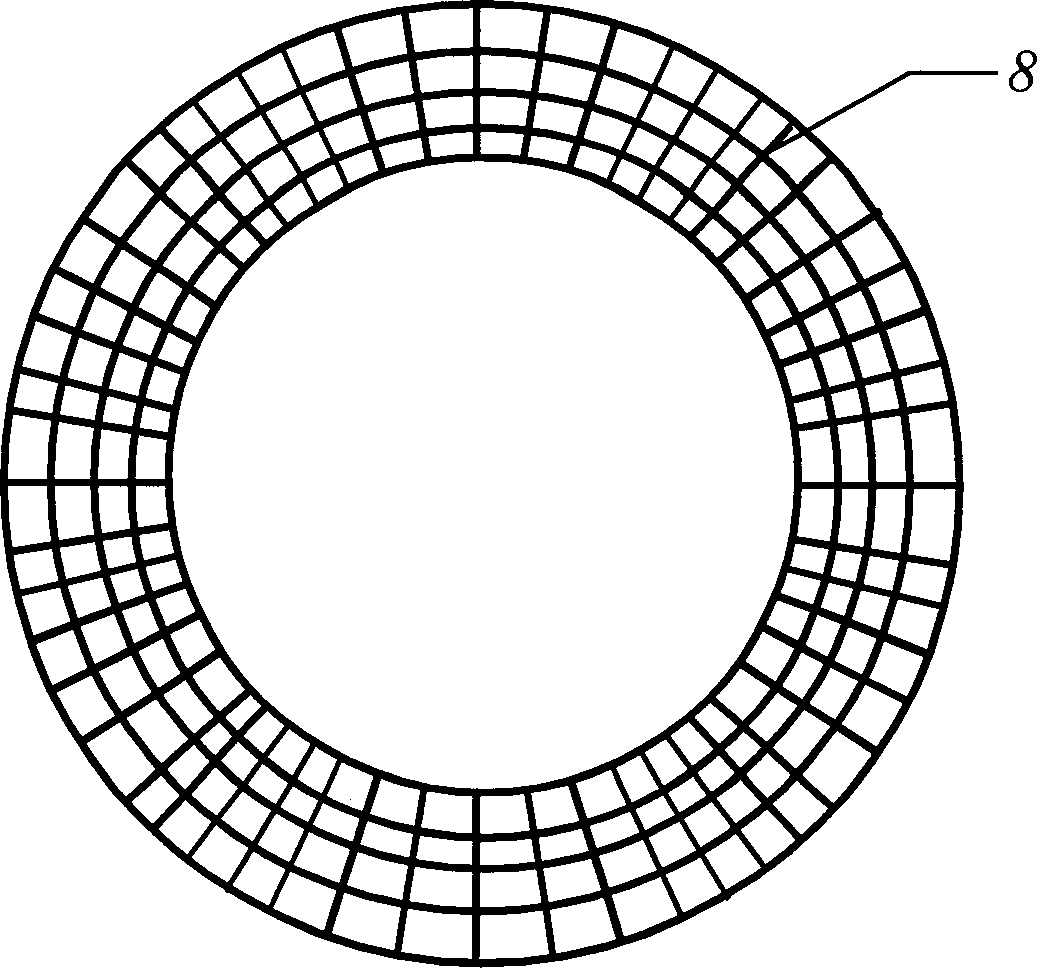

[0016] An embodiment of the present invention is as follows: a cylinder with a diameter of 18m and a height of 21m has an upper wall thickness of 0.35m, and the wall thickness of the tube foot of 0.5m is 0.50m, such as Figure 1 to Figure 4 As shown, vertical holes with a diameter of 0.15m are set on the wall along the circumference at an interval of 1.0m, and the holes are used to place high-pressure water, air pipes and mud discharge pipes alternately. High-pressure water nozzles and high-pressure air nozzles are arranged in the cavity, respectively connected to the high-pressure water pipes and high-pressure air pipes in the vertical holes; , The height of the angle steel is 100mm ~ 150mm, and the mesh of the grid steel sheet is a rectangular hole of 50mm×50mm.

[0017] After the cylinder is prefabricated, the high-pressure water pipe, high-pressure air pipe and mud discharge pipe are installed in the vertical holes reserved on the cylinder wall, and then the high-pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com