Optical disk device and incline detection method

A technology of optical disc device and tilt detection, which is applied in the direction of using optical device, beam guiding device, recording/reproducing by optical method, etc., can solve the problems of inability to read fine signals correctly, temperature not reaching, and inability to record, etc., to achieve Effects of avoiding laser aging, suppressing cost increase, and improving recording quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment

[0149] Refer to the following Figure 25 ~ Figure 31 , to describe the second embodiment in detail, this is the case where only the disc tilt detection method described in the first embodiment is applied to the prior art 1.

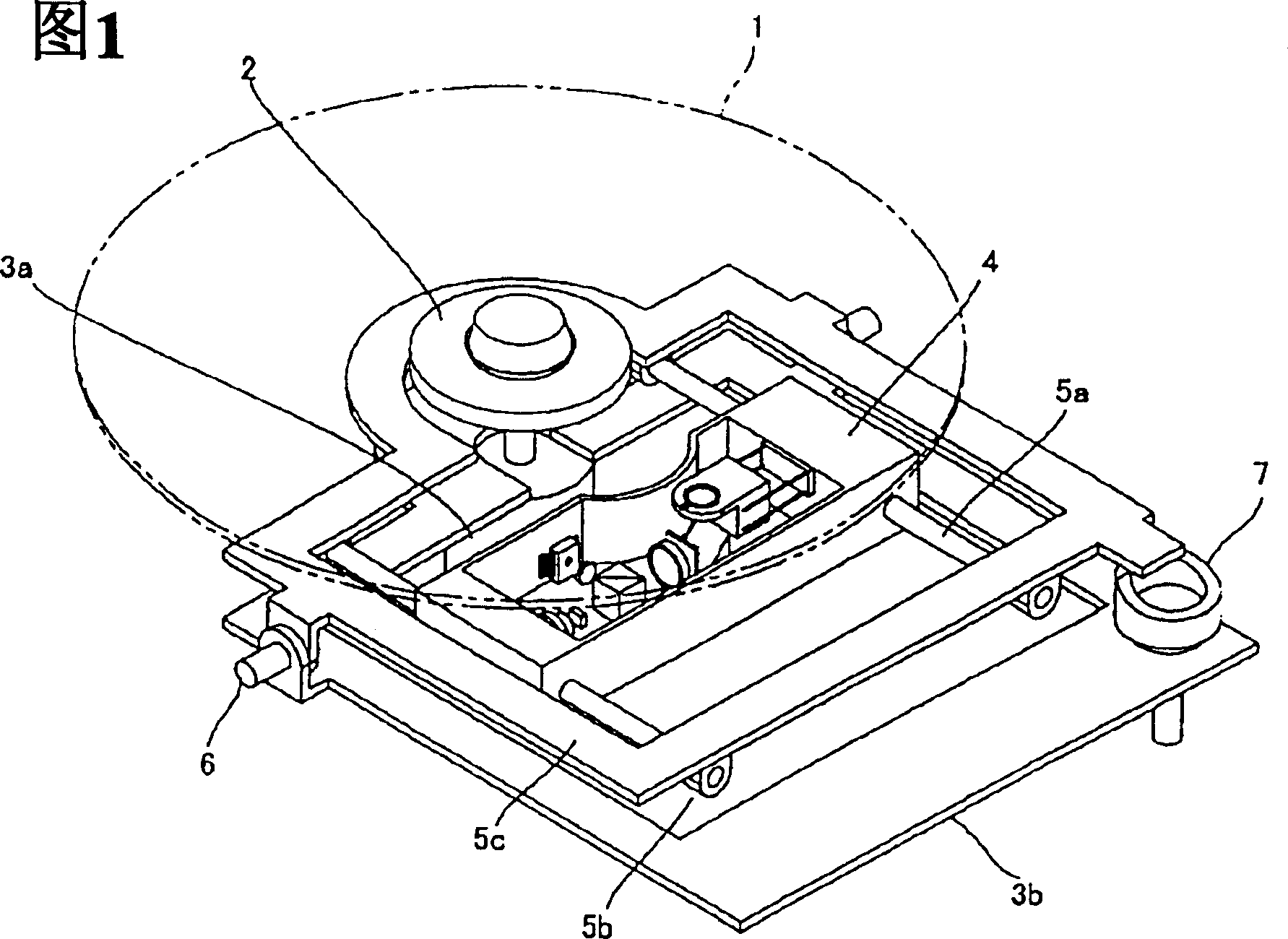

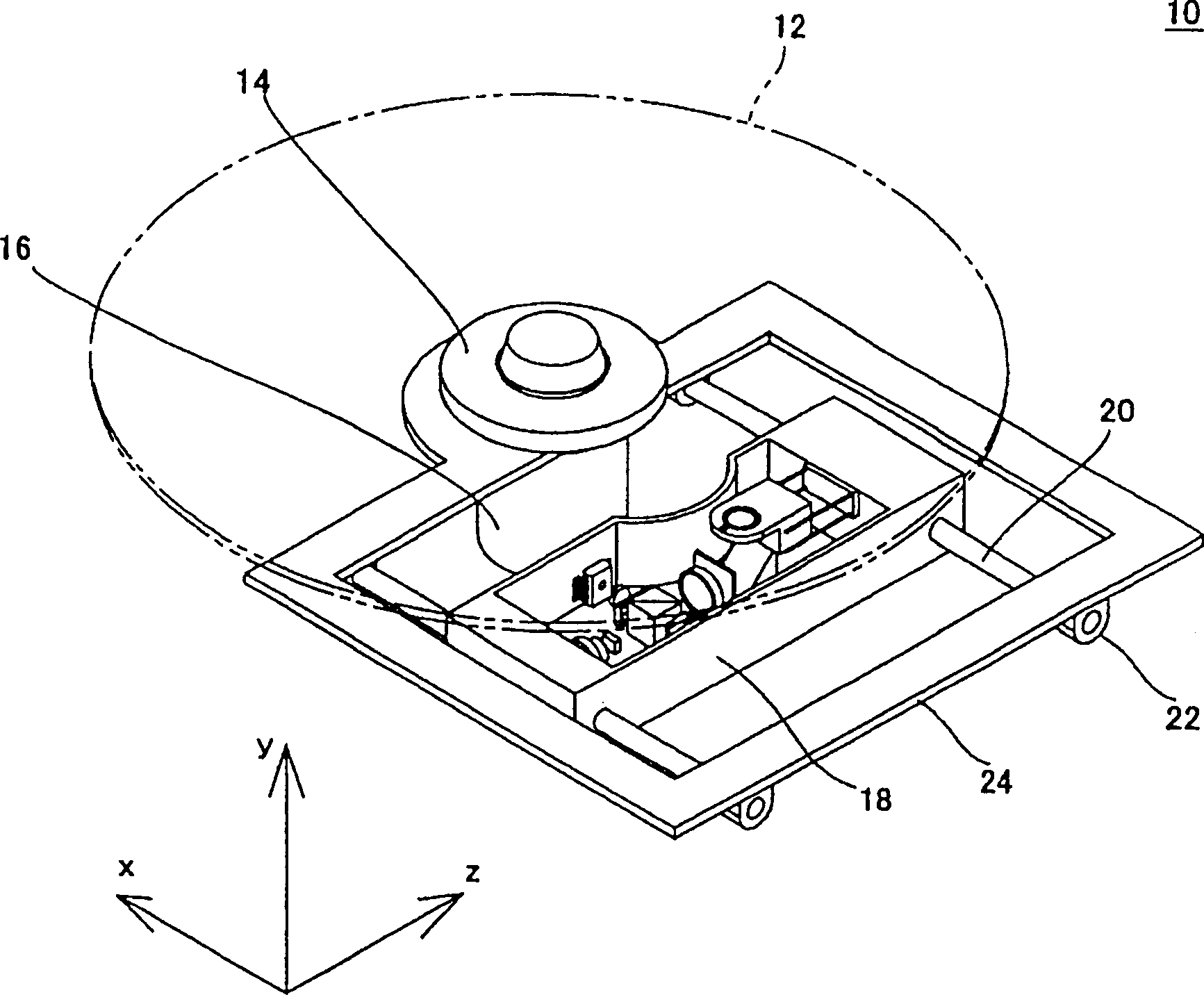

[0150] exist Figure 25 In the optical disc device 10 shown, the optical disc 12 as a signal recording and reproducing body is placed on the turntable 14, driven by the spindle motor 16 to rotate, and receives the light irradiation of the optical sensor 18, so as to record the signal on the optical disc 12, or from the optical disc 12 replay the signal. The optical sensor 18 is supported by a shaft 20 a and is movable in the axial direction of a shaft 20 supported by a shaft bracket 22 . The axle support 22 is secured to an axle support chassis 24 .

[0151] The spindle motor 16 is fixed to a spindle motor chassis 84 , and the spindle motor chassis 84 and the shaft holder chassis 24 are connected by a support shaft 86 . Also, a cam 88 for vertically o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com