Floating coaxial connector

A coaxial connector, floating technology, applied in the direction of connection, two-part connection device, device to prevent wrong connection, etc., can solve the problem of affecting signal transmission, increasing the loss of electrical return loss, affecting high-frequency impedance matching, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

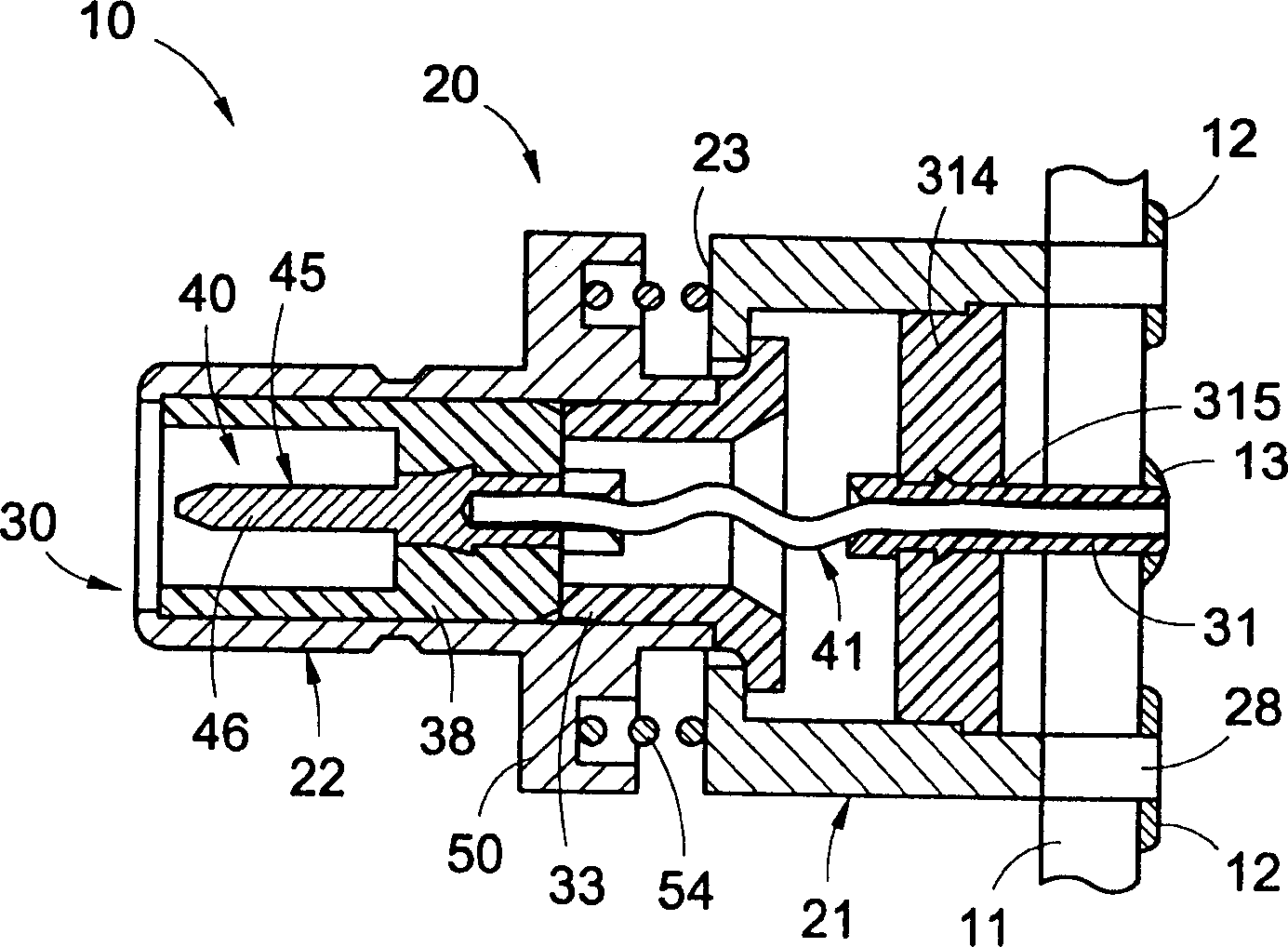

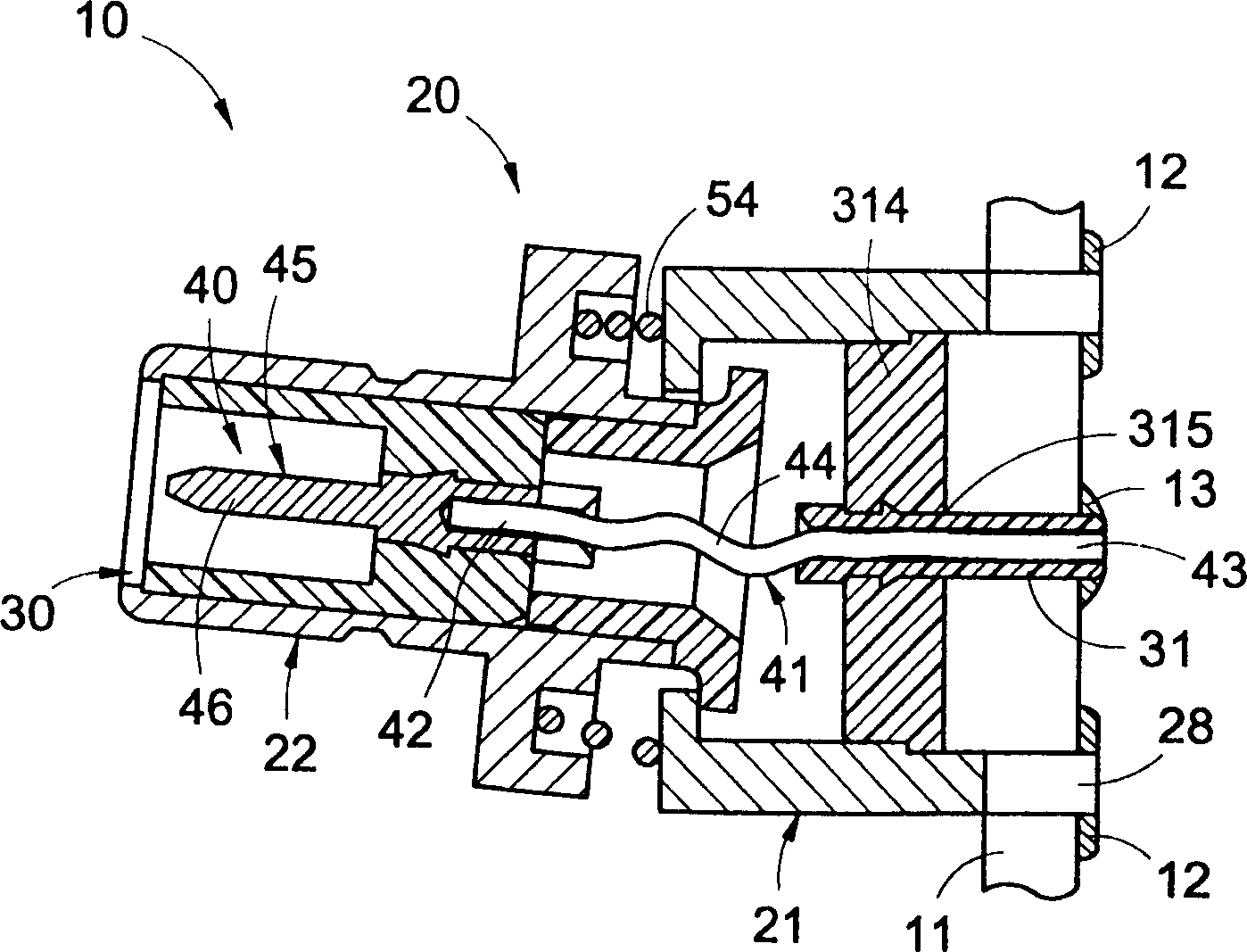

[0022] see figure 1 As shown, the floating coaxial connector 10 of the present invention includes a body assembly 20 , an insulating element assembly 30 , and a contact element assembly 40 . The coaxial connector 10 is fixed on a printed circuit board (PCB) 11 by soldering.

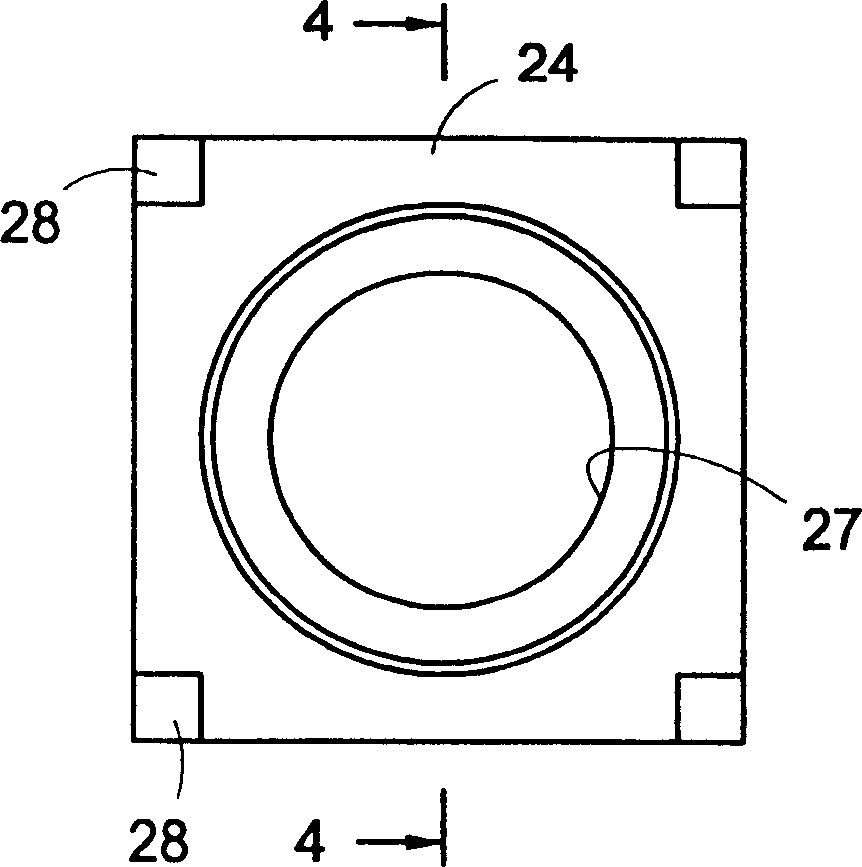

[0023] Body combination 20 comprises a rear body 21, such as image 3 and Figure 4 As shown, it has a front and rear face 23,24. A stepped cylindrical through hole 25 terminates internally in an annular flat bottom 26 which extends axially to the rear face 24 . The annular flat bottom 26 defines a borehole 27 .

[0024] The rear body 21 also includes four equidistantly spaced legs 28 protruding rearwardly from the rear face 24, which can be accommodated in small holes in a printed circuit board (PCB) 11 or a switchboard. The legs 28 can be connected to conductive pins on the PCB 11. Line 12 to facilitate grounding of body assembly 20 .

[0025] The body assembly 20 also includes a front body 22 whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com