Rotating disk style multi-position automative polisher

An automatic polishing, multi-station technology, used in polishing machine tools, manufacturing tools, metal processing equipment, etc., can solve the problems of operator health damage, heavy work and inefficiency, dust pollution, etc., to reduce processing costs and processing costs. Low, easy-to-handle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

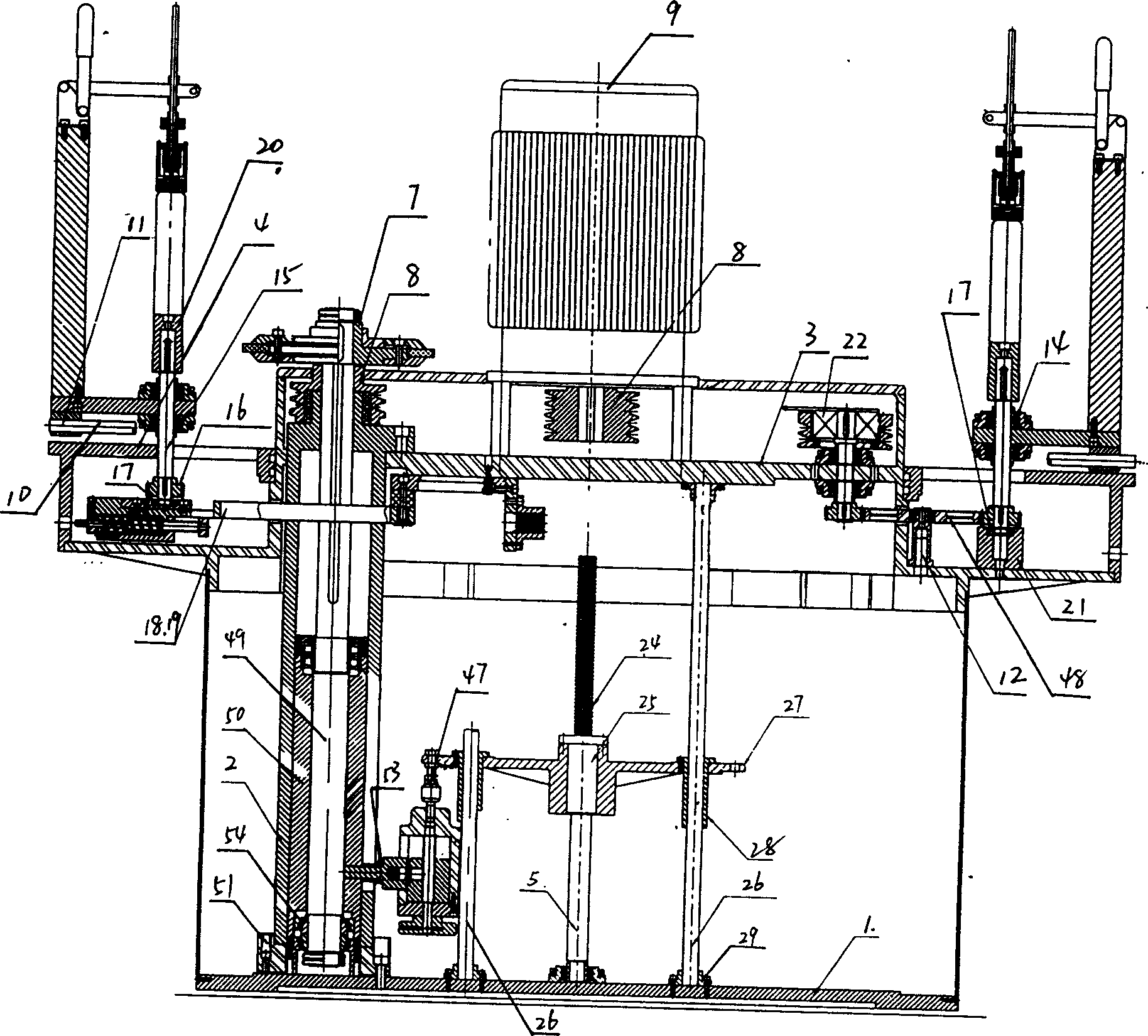

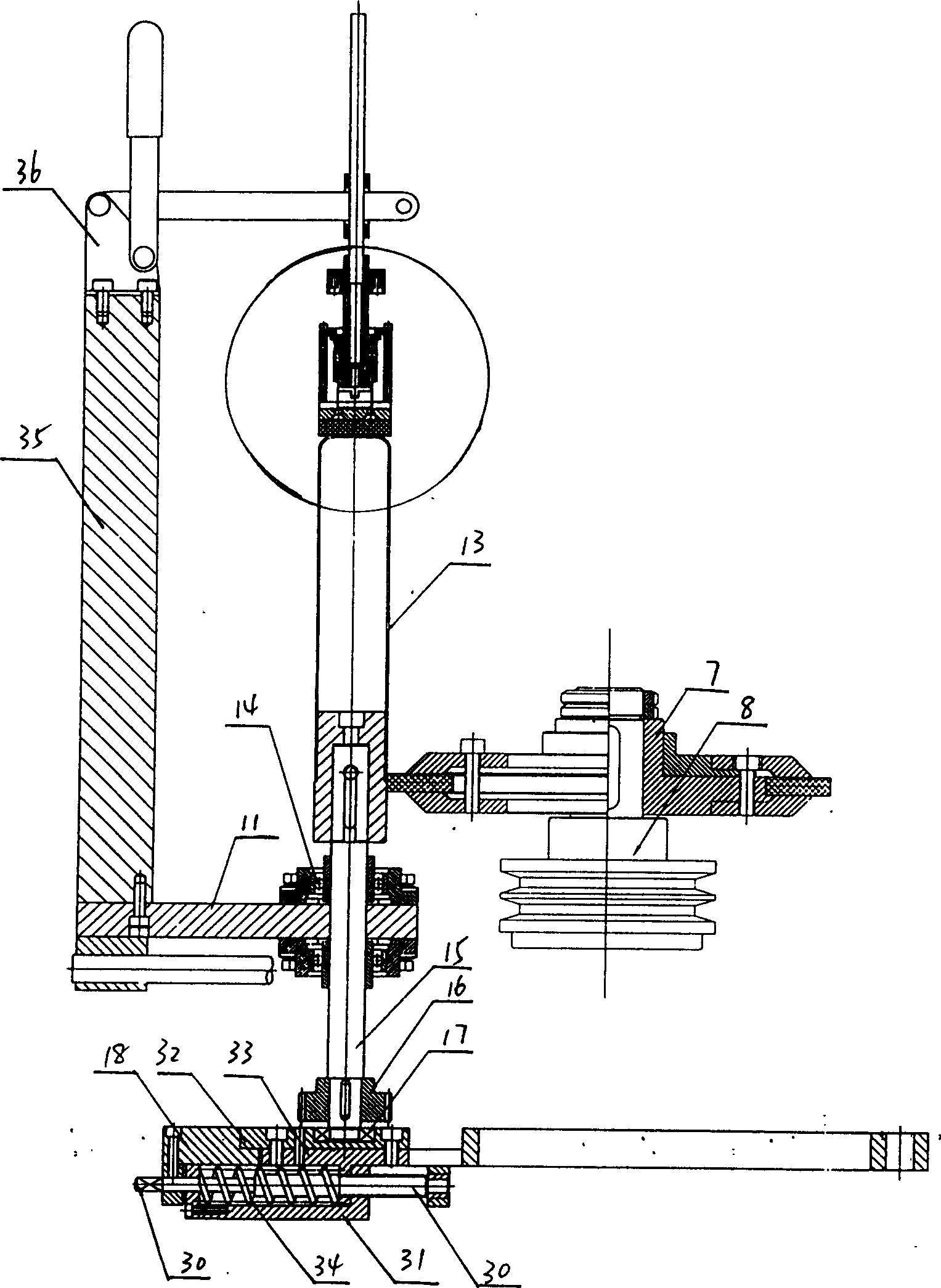

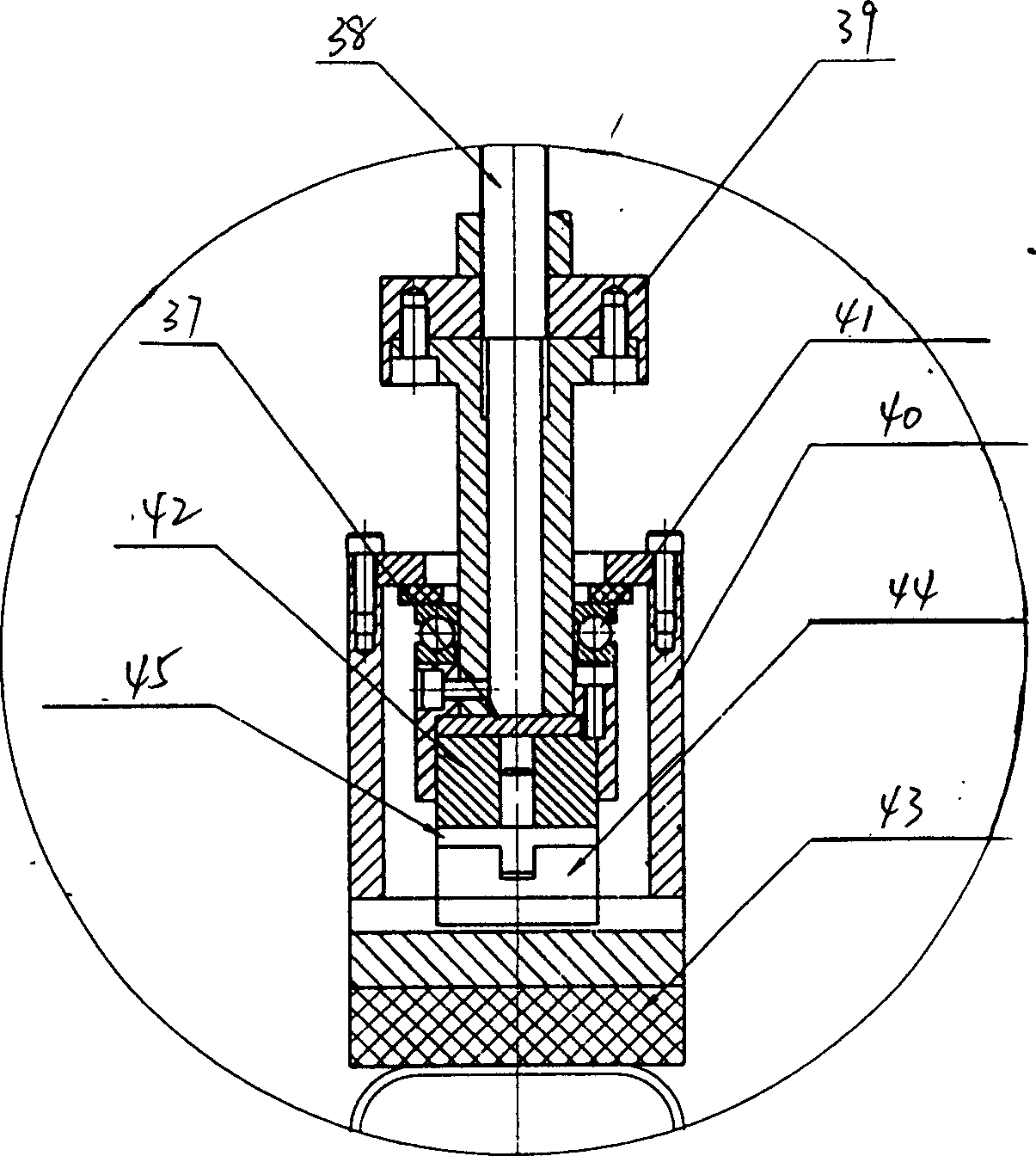

[0022] The present invention will be further described below in conjunction with embodiment. The three-layer structure adopted by the present invention is an important feature of this machine; this machine is composed of several large parts to form the skeleton of the whole machine; chassis 1, column 2, tray 3, turntable 4 and guide rail 5 supporting the Y-axis lifting movement. Their combination is roughly divided into three layers: the bottom chassis 1, the middle tray 3, and the high-level turntable 4. A column 2 is erected on the chassis 1, and the column 2 supports the tray 3, and the turntable 4 is placed on the tray 3. Between the chassis 1 and the pallet 3 is fixed a guide rail 5 supporting the Y-axis lifting movement. The chassis 1 of the bottom layer, the tray 3 of the middle layer and some columns 2 fixed between them are fixed. And the turntable 4 of high level is supported by pallet 3, can only turn a station successively by program setting under the drive of in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com