Heating body valve

A technology of valves and heaters, applied in heating methods, lighting and heating equipment, valve lifts, etc., can solve problems such as valve seat stroke height restrictions, and achieve the effect of high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

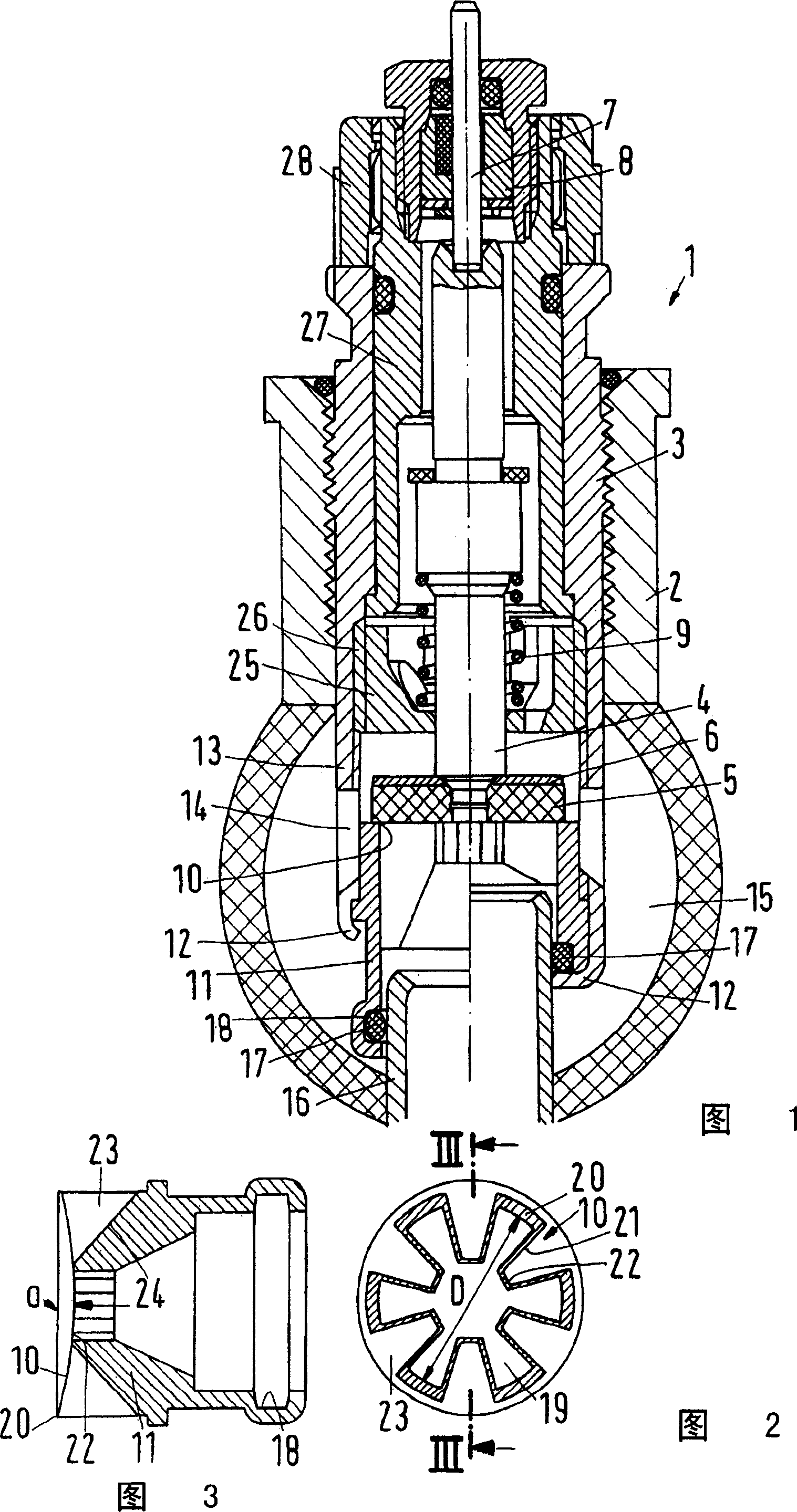

[0025] The heater valve 1 shown in FIG. 1 has a housing 2 into which a valve assembly 3 is screwed. The valve assembly 3 has a valve stem 4 at one end of which a valve member 5 is mounted. The valve element 5 consists of an elastomer material and is supported by a support disc 6 . The valve element 5 is substantially in the shape of a flattened cylinder.

[0026] The valve stem 4 is actuated by an operating pin 7 which is guided by a packing sleeve 8 . The operating pin 7 acts on the valve stem 4 to overcome the force of the opening spring 9 .

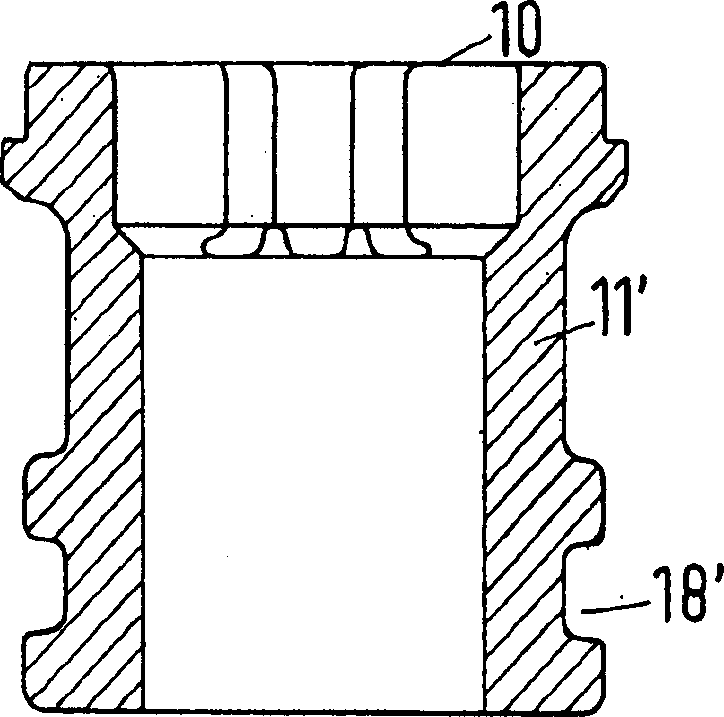

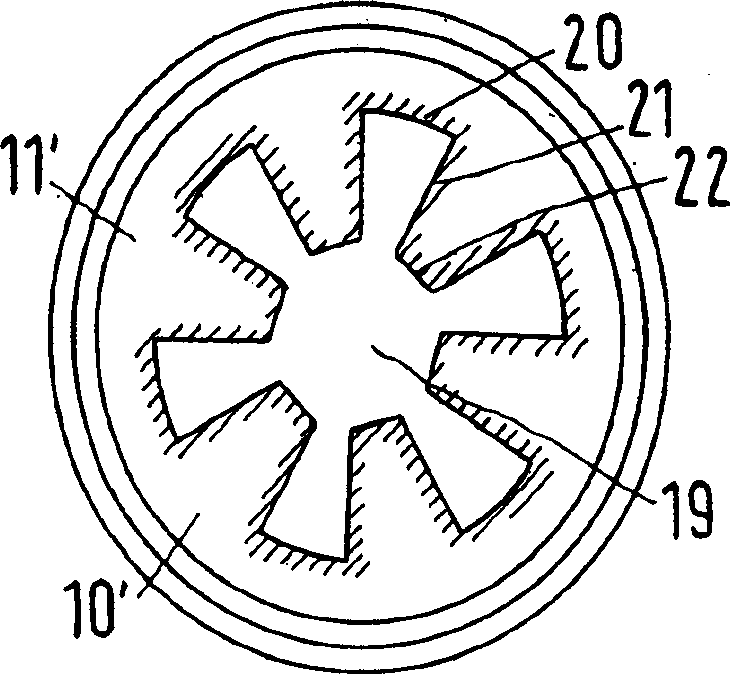

[0027] The valve element 5 interacts with a valve seat 10 on a valve seat element 11 . The valve seat element 11 is shown in two different forms in FIG. 1 . In the left half of FIG. 1, the valve seat element 11 is connected to the valve assembly 3 via a crimp connection 12, wherein the valve assembly 3 has an extension 13, in which a series of holes 14 are again arranged, which allow The heat transfer liquid flows from the valve t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com