Joint structure and method for building structural component unit

A joint method and technology for building components, which are applied in the direction of building structure and construction, can solve the problems of offset of the column connecting part, inconvenient bolt tightening operation, and inconvenient confirmation of the bolt tightening state, so as to achieve stable joint state, The effect of convenient connection work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

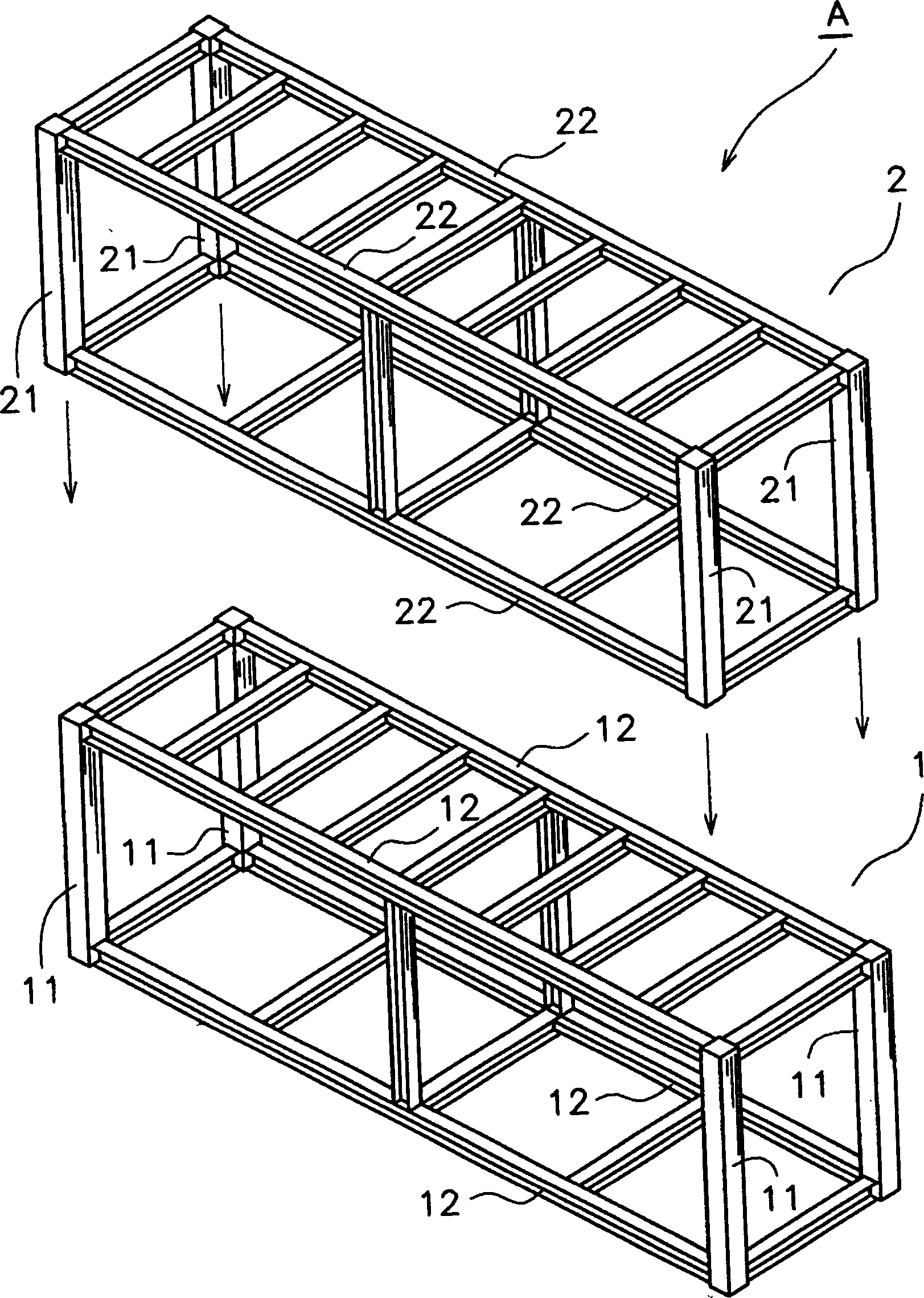

[0018] Embodiment 1, the present invention will be described below according to the accompanying drawings. Such as figure 1 As shown, 1 and 2 are building components that constitute units, and the present invention relates to the invention of the connection structure and connection method of building components 1 and 2. On the lower building component 1, the upper building component 2 is superimposed, and the unit room A with 2 or 3 floors is formed after the two are joined. The building elements 1, 2 are composed of a plurality of columns 11, 21 and beams 12, 22. In this embodiment, when the above-mentioned building components 1 and 2 are stacked, the upper end of the lower column 11 constituting the lower building component is connected to the lower end of the upper column 21 constituting the upper building component 2 .

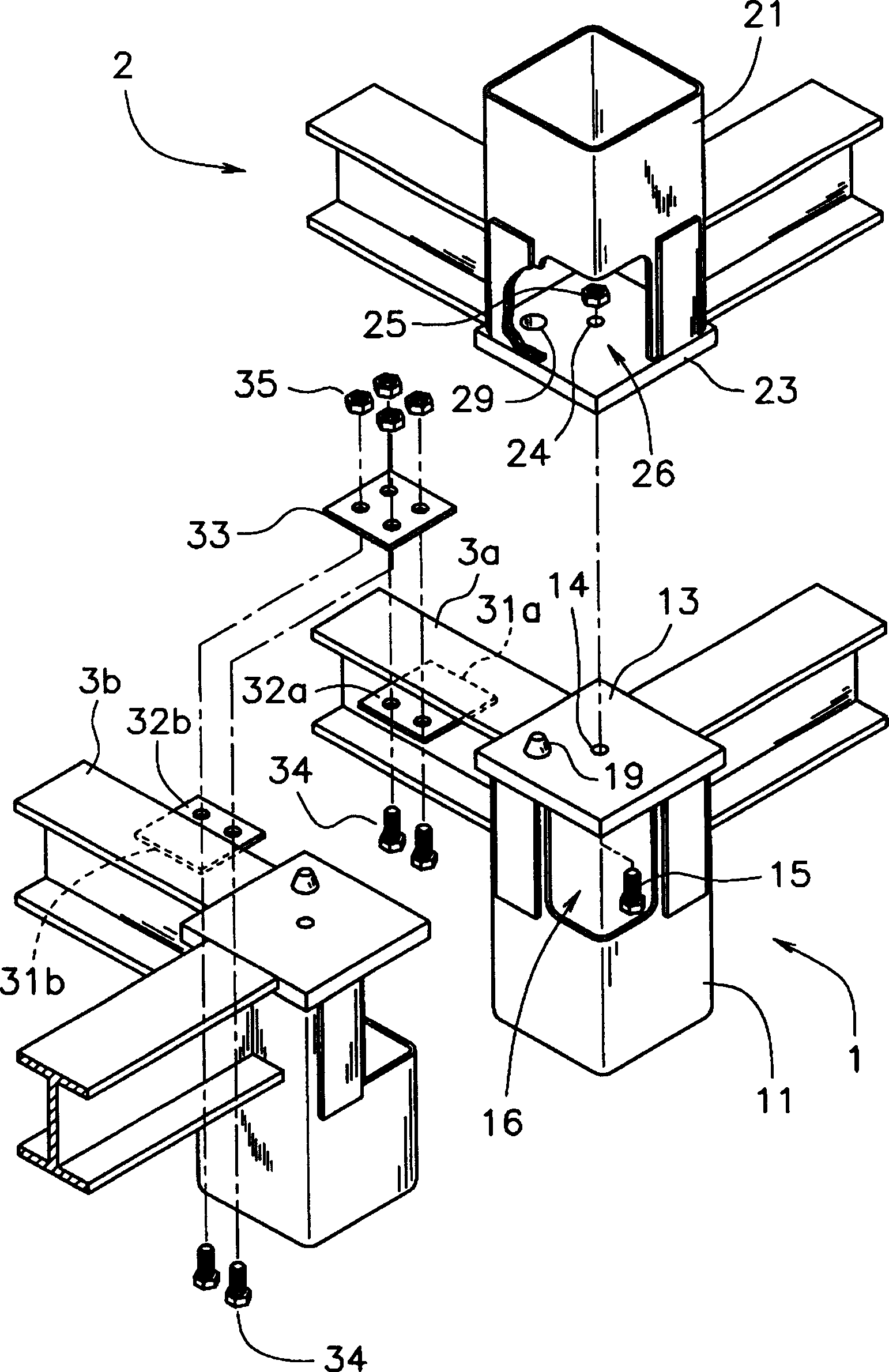

[0019] Such as figure 2 As shown, the column 11 for the lower layer and the column 21 for the upper layer in this embodiment are composed of a cylindr...

Embodiment 2

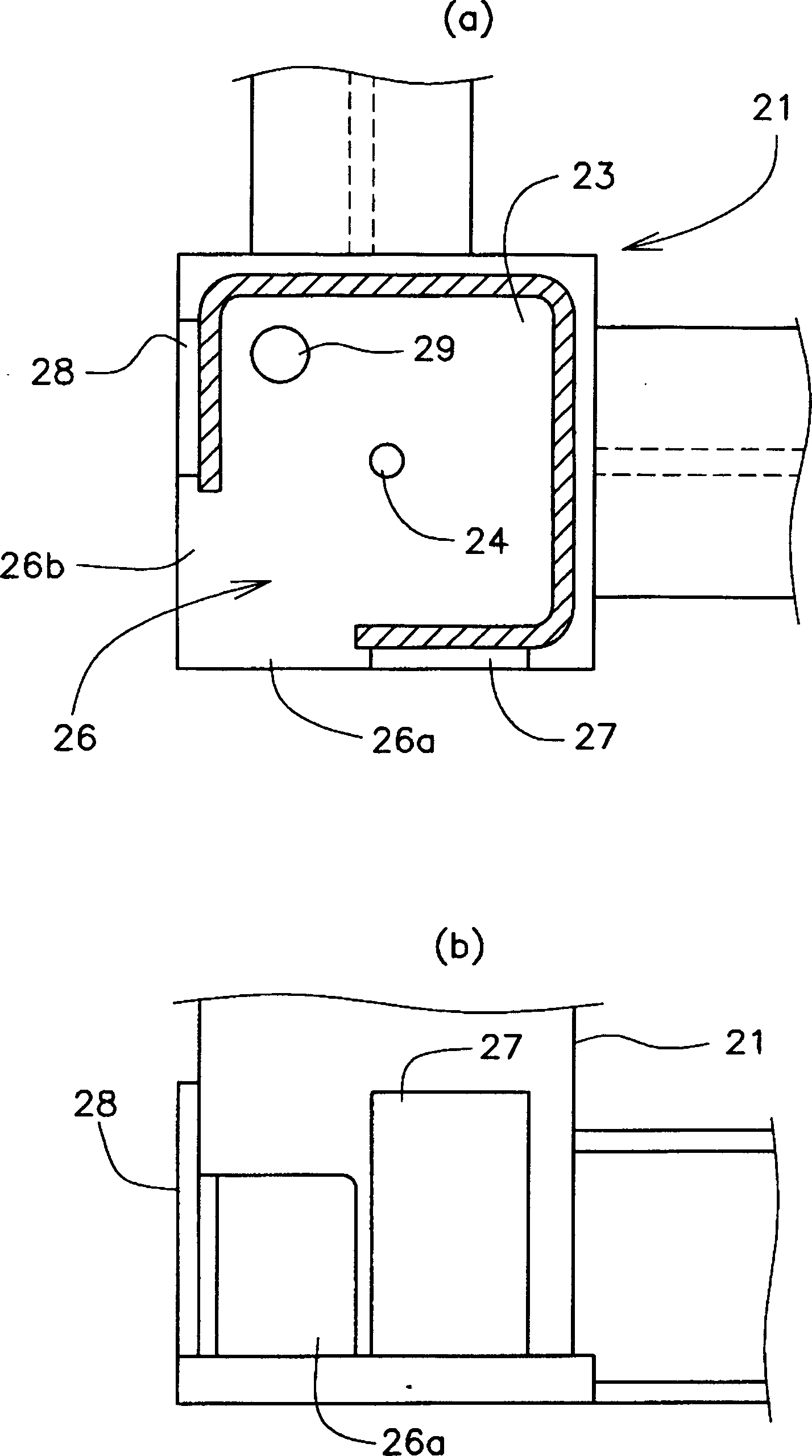

[0030] Embodiment 2, the second embodiment of the connection structure will be described below. Such as Figure 5 As shown, this is a structure in which the lower column 111 constituting the lower building member 101 is connected to the upper building member 102, and is roughly the same as the first embodiment. The difference is that the upper end of the column 111 for the lower layer in this embodiment is provided with a horizontal joint surface 113 , and the center of this surface is provided with a protruding bolt external thread portion 115 along the length direction of the column 111 . Furthermore, no notch is provided on the side surface of the column 111 for the lower floor, and of course there is no reinforcing plate. On the other hand, the upper column 121 constituting the upper building member 102 is provided with a notch 126 in the same structure as the first embodiment, and reinforcing plates 127, 128 are provided on both sides thereof.

[0031] When the superstr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com