Melt sampler suitable especially for cinder floating over metal melt

A sampler and metal technology, applied in sampling, sampling devices, instruments, etc., can solve problems such as fragile and porous samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

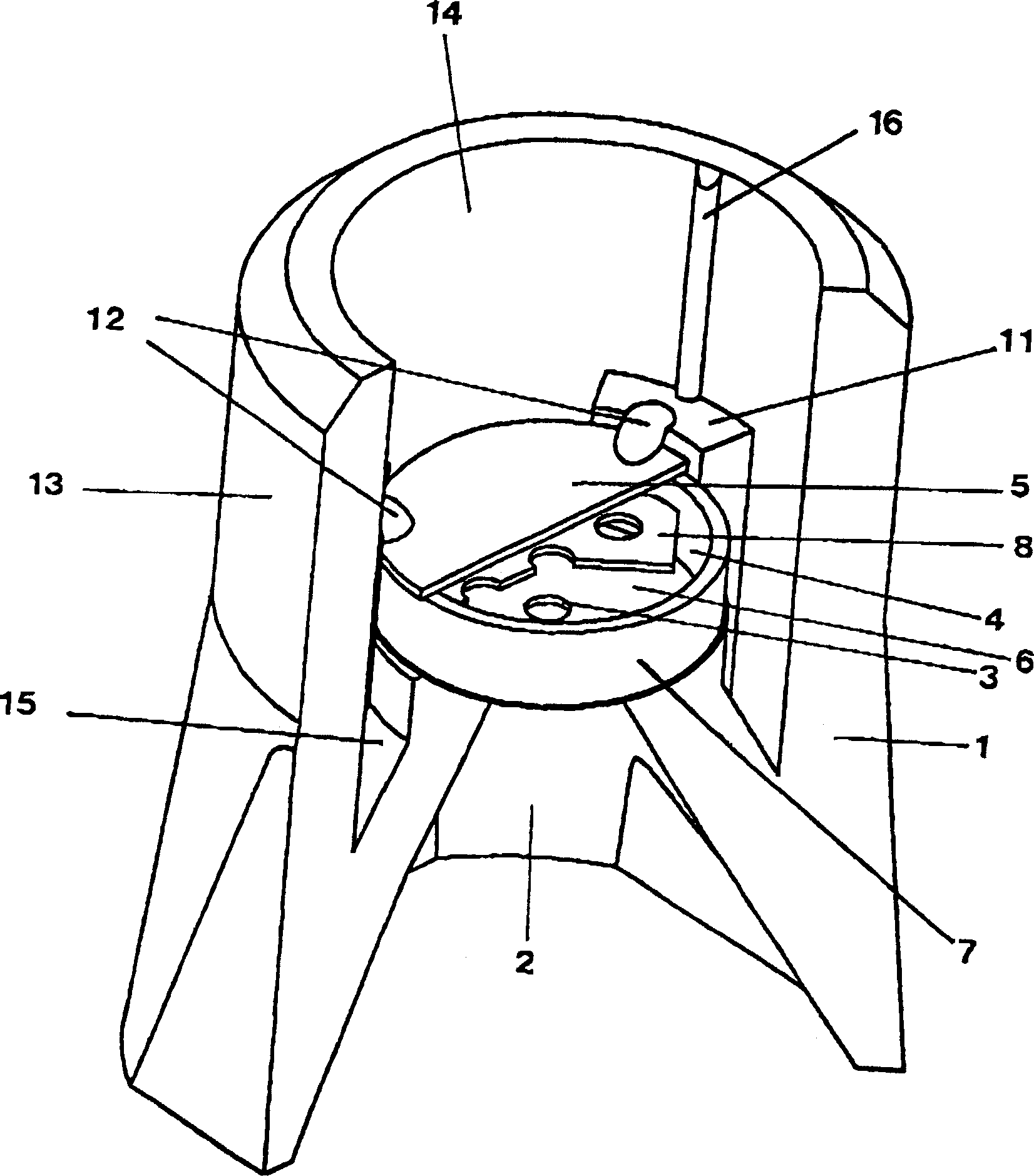

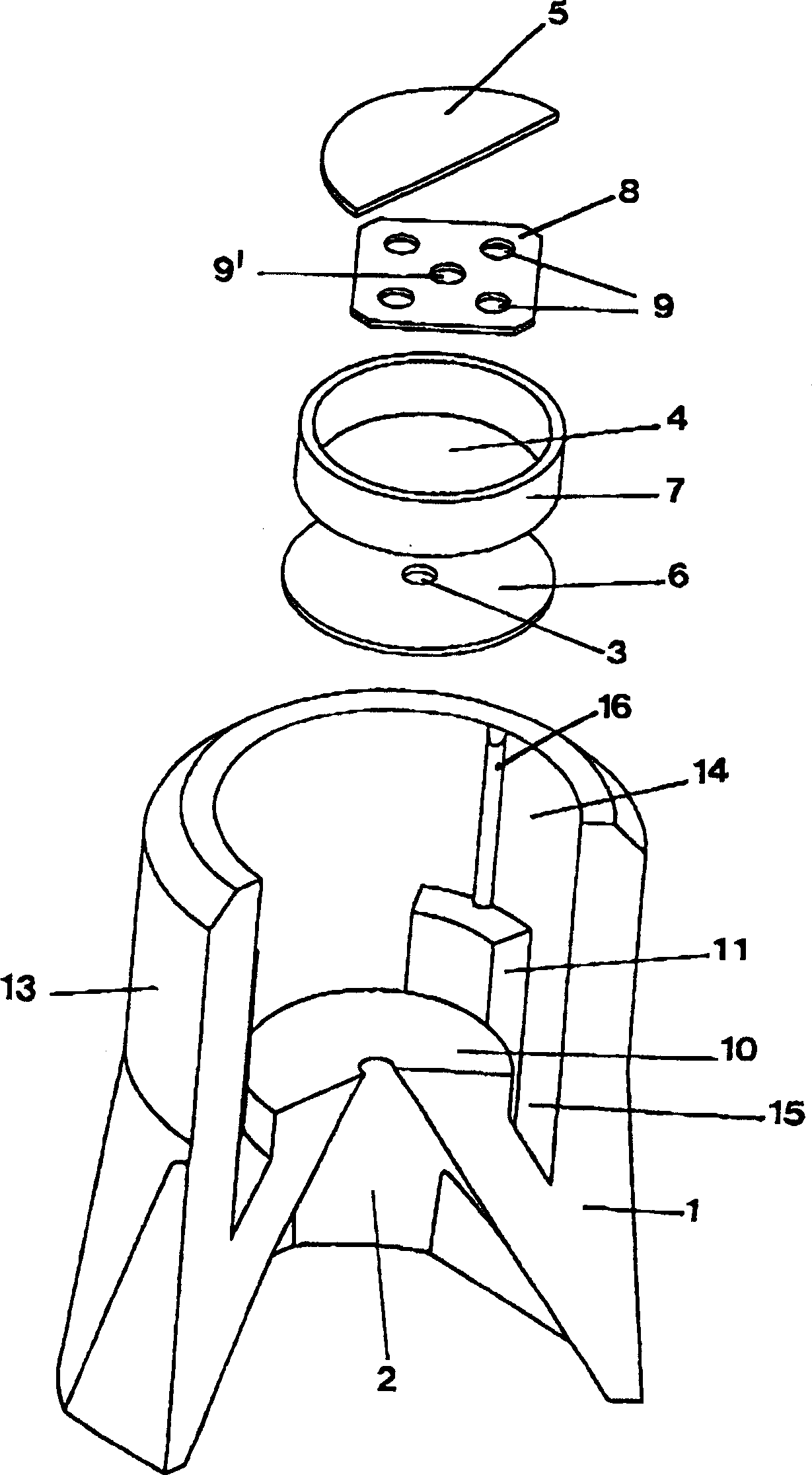

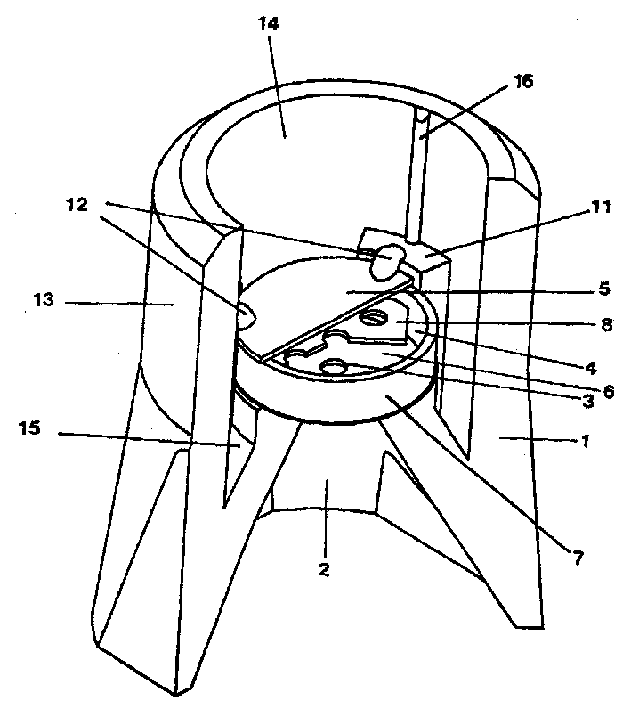

[0011] The housing 1 of the sampler is made of molding sand. It has a funnel-shaped inlet 2 which leads to a sampling chamber 4 via an inlet hole 3 . The sampling chamber 4 is a disk-shaped structure with a circular cross section. The sampling chamber walls 5 , 6 forming the base are also made of steel like the annular side wall 7 .

[0012] Inside the sampling chamber 4 , approximately midway between the two chamber walls 5 , 6 there is a partition plate 8 parallel to the chamber walls 5 , 6 . The steel partition plate 8 is provided with a plurality of holes 9, 9'. Around a central hole 9' with a diameter of about 8 mm, there are further four holes 9 with a diameter of about 5 mm, which are preferably evenly distributed around the circumference. It is also possible not to form a central hole or to arrange the spacer plates 8 in other arrangements. The partition plate 8 is fixed on the side wall 7 of the sampling chamber 4 .

[0013] The chamber wall 6 of the sampling cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com