Cryogenic refrigerator and control method therefor

A technology of refrigeration device and control method, which is applied in refrigerators, refrigeration components, cold treatment separation, etc., can solve the problems of load application, driving system and other adverse effects, and high pressure resistance of pressure vessels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

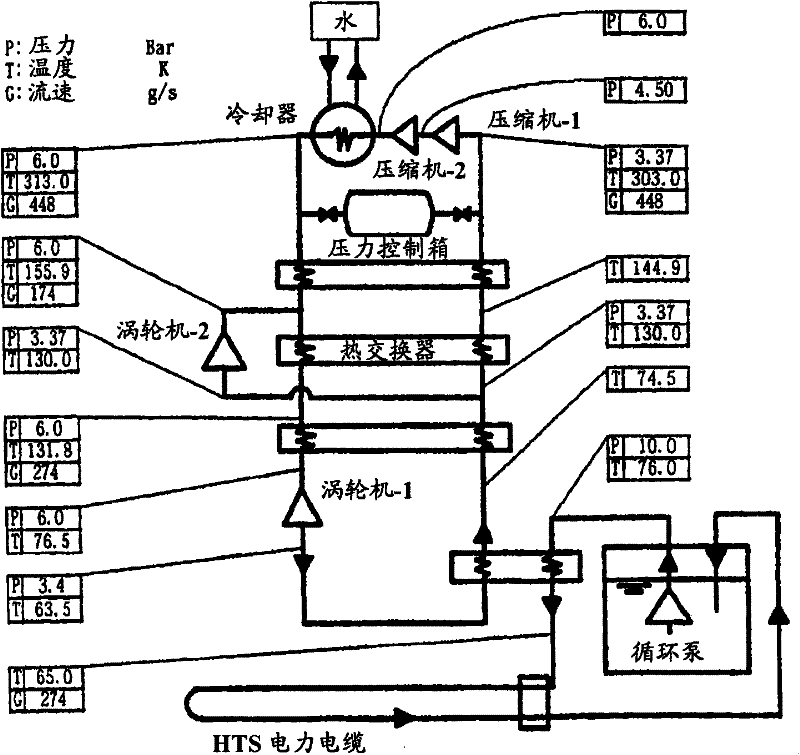

[0081] Figure 5It is a figure which shows 2nd Embodiment of the cryogenic freezer concerning this invention. This example is an embodiment in which the outlet temperature of the cryogenic part is 65K and the cooling capacity is 3kW. P, T, H, and G in the figure represent pressure (bar), temperature (K), and mass flow rate (g / s), respectively.

[0082] In this example, the room temperature compressor 14 is composed of a first-stage compressor 14A that compresses from a specified low pressure (5.57 bar) to a first intermediate pressure (8.03 bar) between the low pressure and high pressure, and compresses from the first intermediate pressure to a high pressure. (11.0bar) second-stage compressor 14B constitutes. Water-cooled gas coolers 15 are provided on the downstream side (high pressure side) of the first-stage compressor 14A and the second-stage compressor 14B, respectively.

[0083] In addition, the expander 18 consists of a first expander 18A that expands from a high pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com