Turn plate drawing die

A technology of drawing die and turntable, applied in the field of turntable drawing die, can solve the problems of high cost, troublesome operation, high precision, etc., and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

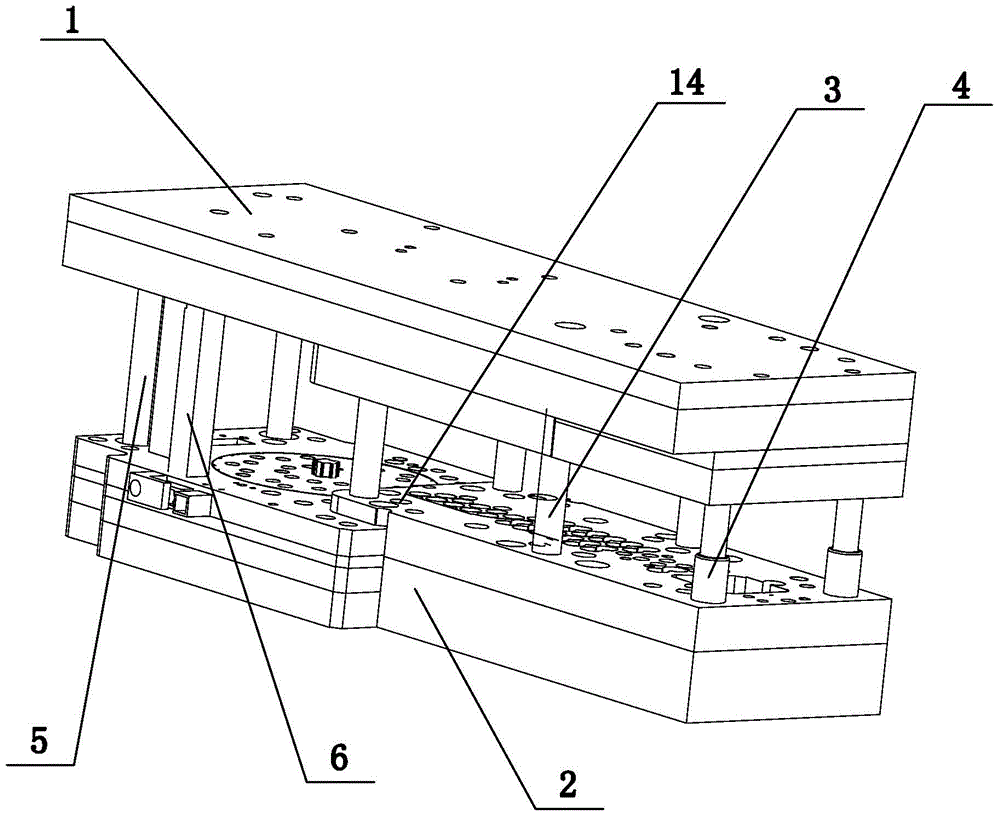

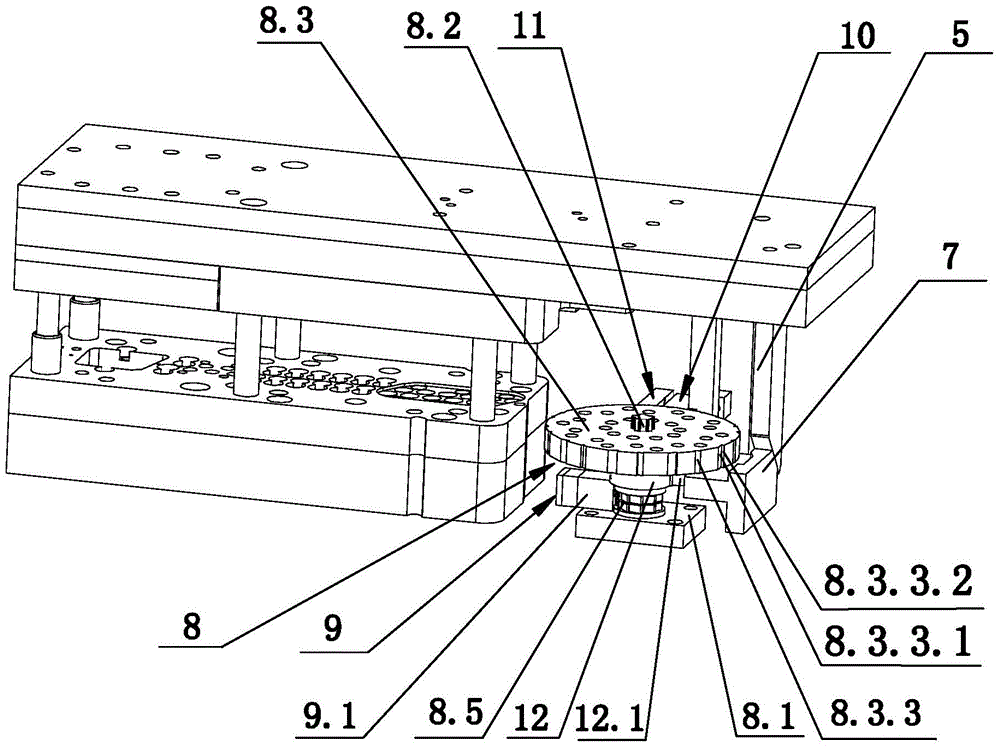

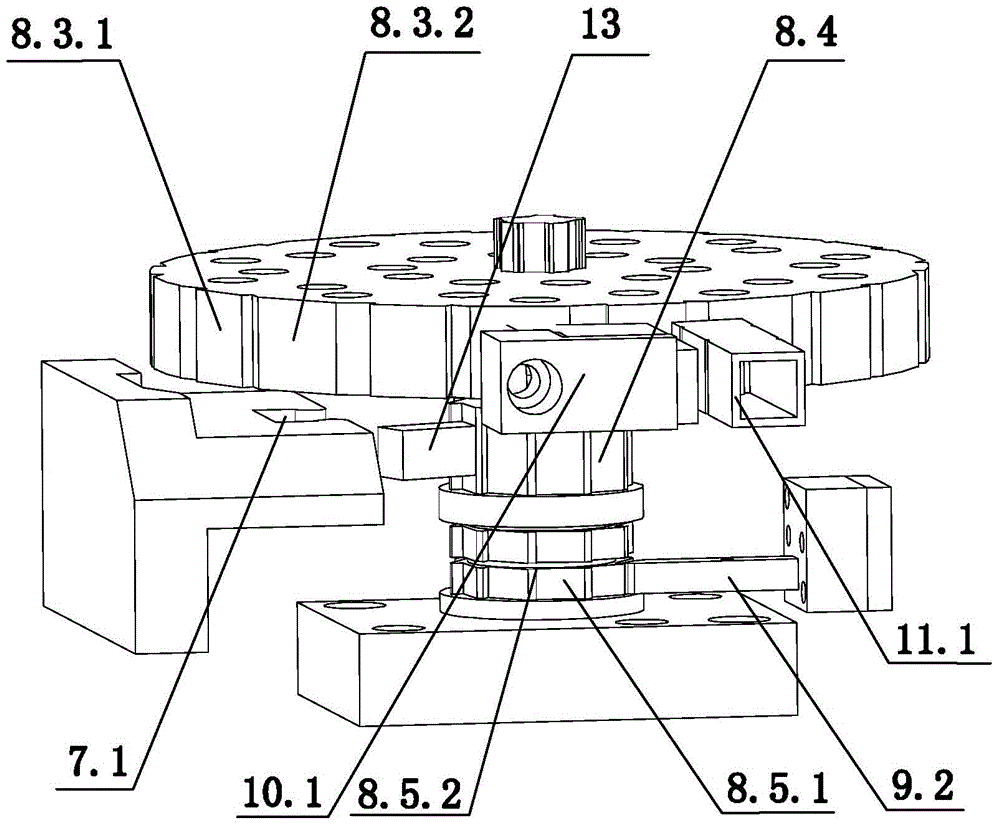

[0030] refer to Figure 1 to Figure 4 As shown, the turntable drawing die of this embodiment includes a control system, an upper mold base 1, a lower mold base 2, and a guide sleeve 3 and a guide post 4 that provide guidance for the relative movement of the upper mold base 1 and the lower mold base 2, The upper mold base 1 and the lower mold base 2 are perforated with a first slider 5 and a second slider 6 that are perpendicular to the upper mold base 1 and the lower mold base 2. A sliding block 5 is slidingly fitted with a third sliding block 7, a rotating mechanism 8 connected to the third sliding block 7, and a first anti-rotation device 9 installed on one side of the rotating mechanism 8, and the second sliding block 6 is fixedly installed There is a positioning mechanism 10 , and the other side of the positioning mechanism 10 opposite to the second slider 6 is provided with a second anti-rotation device 11 .

[0031] By adopting the above-mentioned technical scheme, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com