Gravity crank perpetual motion machine

A technology of perpetual motion and crank mechanism, applied in the direction of engine, machine/engine, mechanical equipment, etc., can solve the problems of increased centrifugal friction, unfavorable perpetual motion and force energy, and poor efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

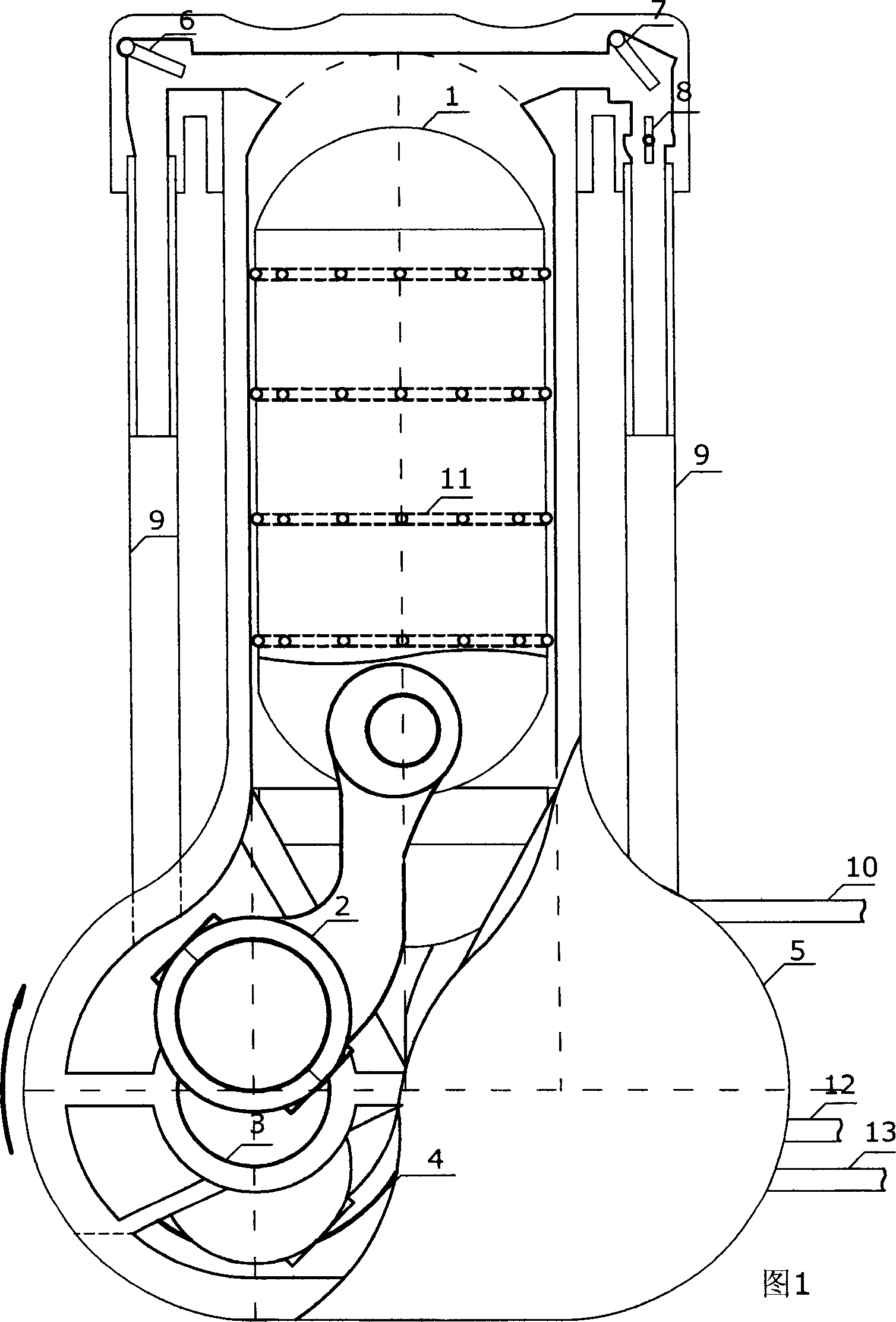

[0041] Fig. 1 is the gravity piston (1), connecting rod (2), crankshaft (3), flywheel (4), cylinder block and housing (5), air inlet circulation valve (6), outlet of gravity crank perpetua mobilia of the present invention Air circulation valve (7), speed control valve (8), air circulation passage (9), passage from vacuum to pressure control device (10), rolling friction parts (11), passage to temperature-controlled cooling and lubrication system components (12 ), (13) and related cooling and lubrication systems, load or power transmission mechanisms and parts.

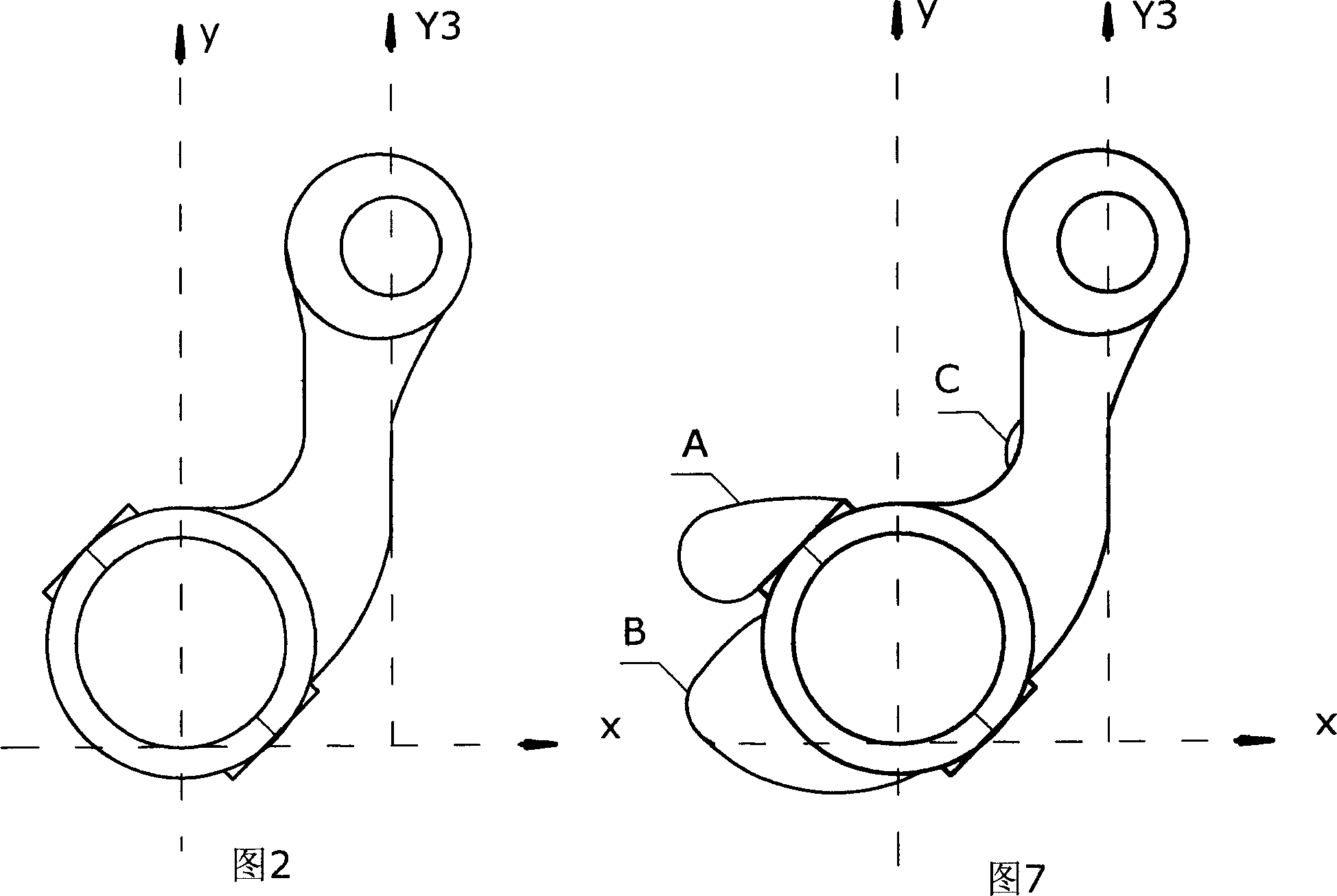

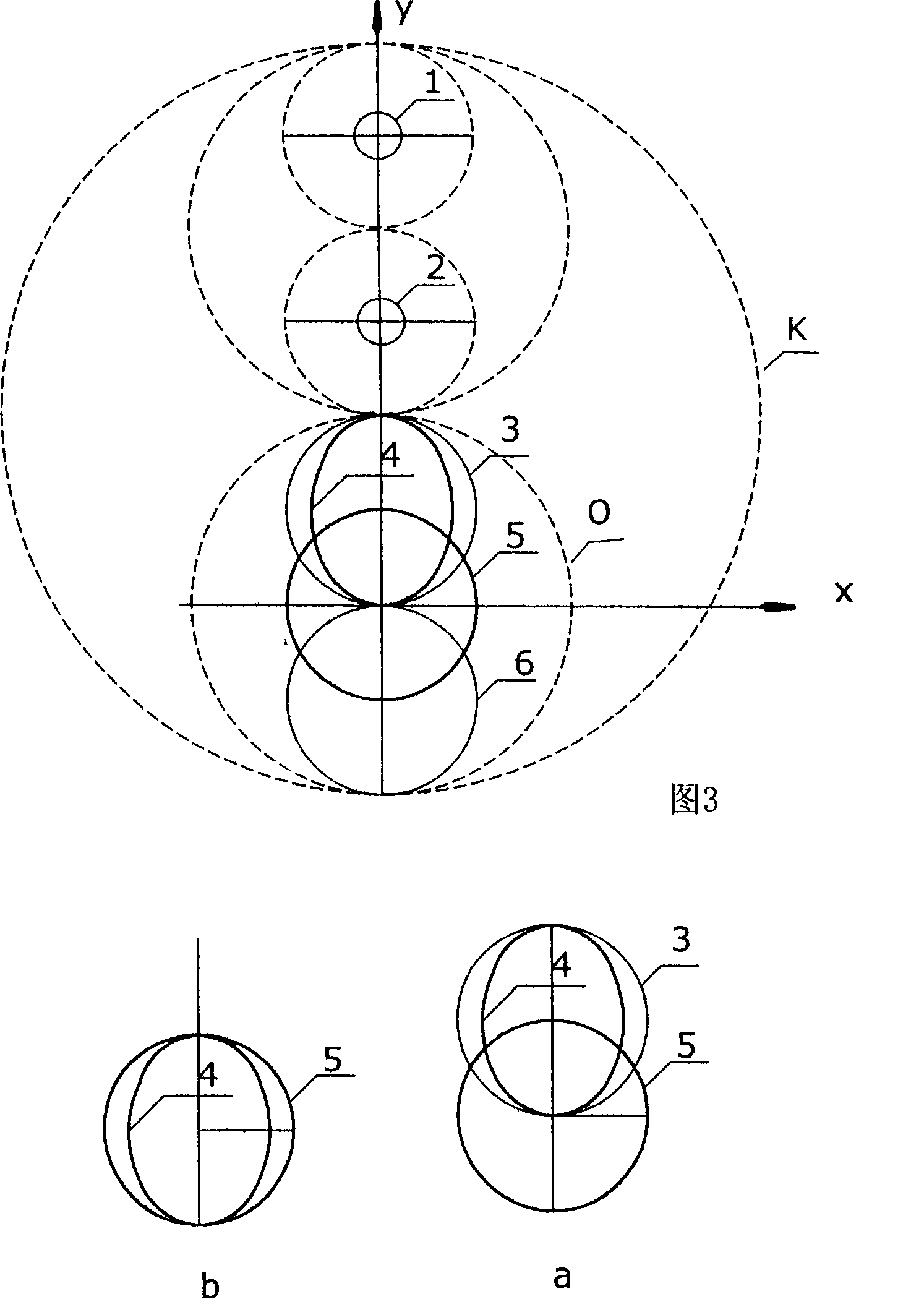

[0042] The design or setting result of the above-mentioned technical scheme is: under the gravitational action of the gravitational acceleration of the earth or the planet, it acts on the center of the gravity piston. Make the gravity piston go down according to the set straight track, and pass the reverse written percentage symbol of the mechanism deviation design and gravity deviation setting This transmission of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com