Variable-accuracy electronic laser two-dimensional dip measuring method and device

A variable precision and measurement method technology, applied in the direction of measuring devices, optical devices, electrical components, etc., can solve the problem of not being able to meet high-precision inclination angles, and achieve the effect of low cost and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and the embodiments completed by the inventor according to the technical solution of the present invention.

[0028] 5.1 Variable precision laser electronic two-dimensional inclination measurement method

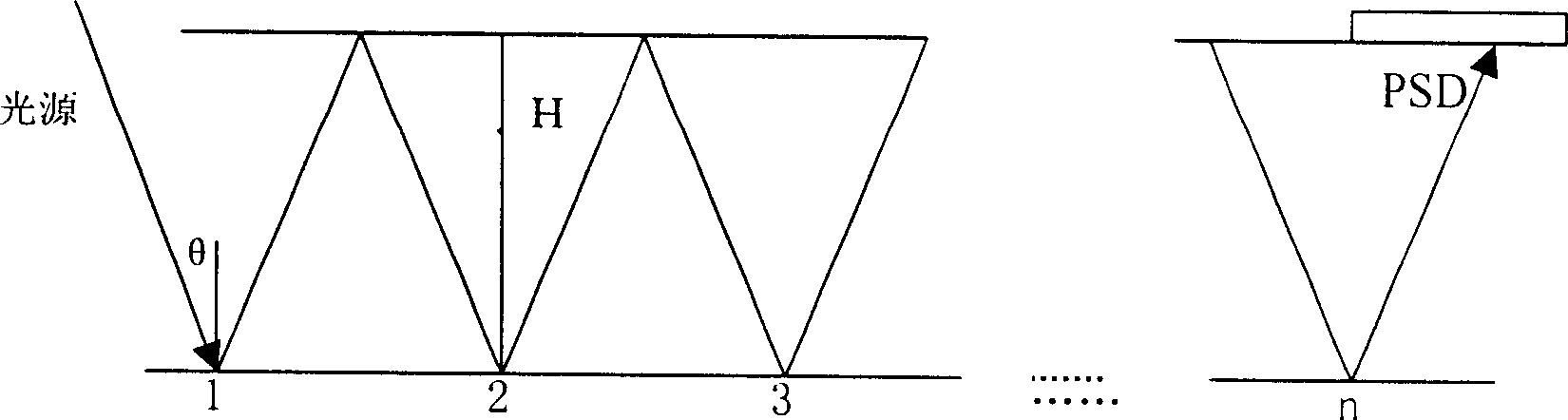

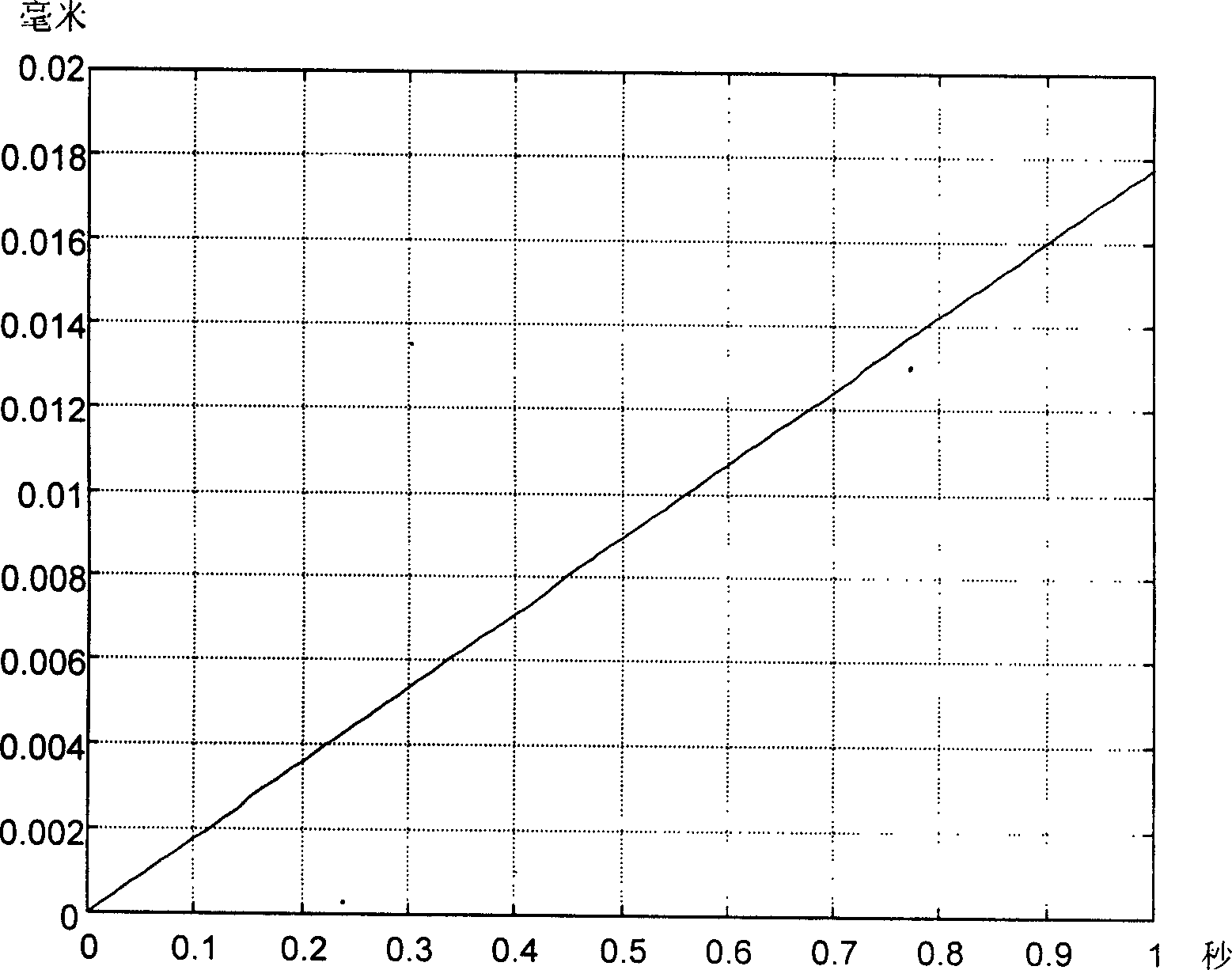

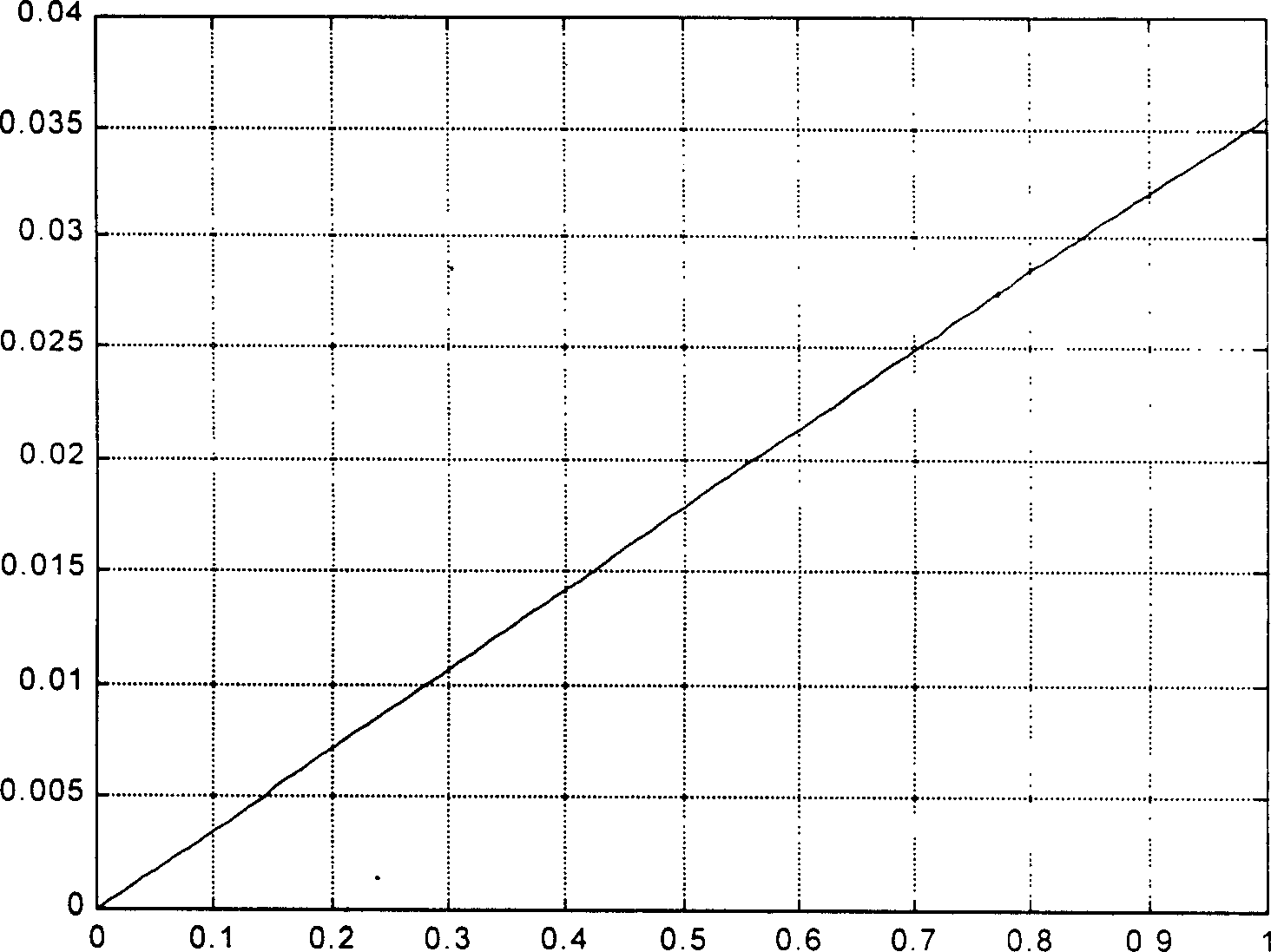

[0029] see Figure 1~3 ; figure 1 , Schematic diagram of the principle of the variable precision laser electronic two-dimensional inclination measuring instrument; figure 2 H=50mm θ=8 degrees β-D relationship curve; image 3 H=100mm θ=8 degrees β-D relationship curve.

[0030] The variable precision laser electronic two-dimensional inclination measurement method is carried out in the following manner:

[0031] 1) A photoelectric device is installed above the liquid level or the surface of the floating object, and a reflector is arranged on the liquid surface. The light emitted by the light source is collimated by the optical system and then incident on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com