Elastomer creeper tread

A track shoe and elastic body technology, applied in the field of elastic body track shoes, can solve the problems of large friction coefficient, difficult manipulation, and inability to turn smoothly, and achieve the effects of small ground contact area, prolonging service life, and improving riding comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

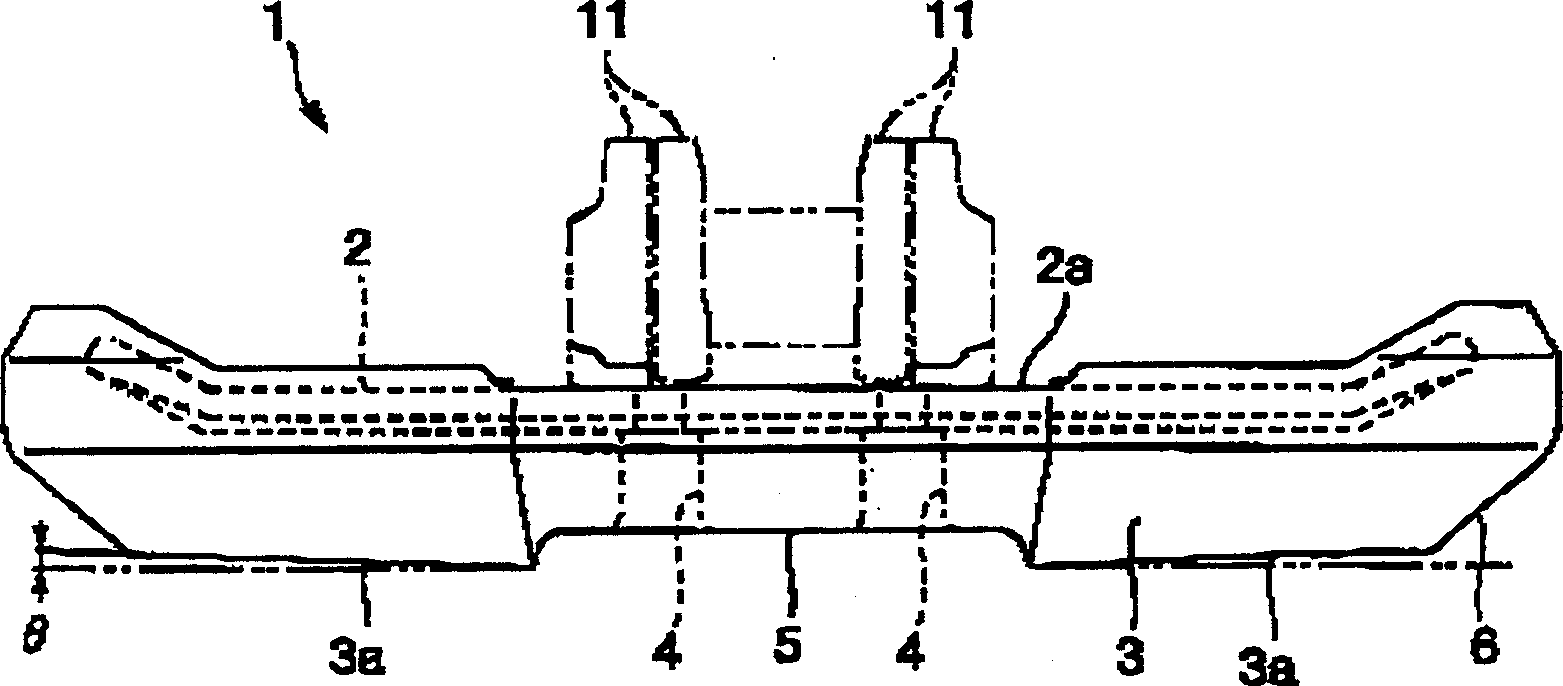

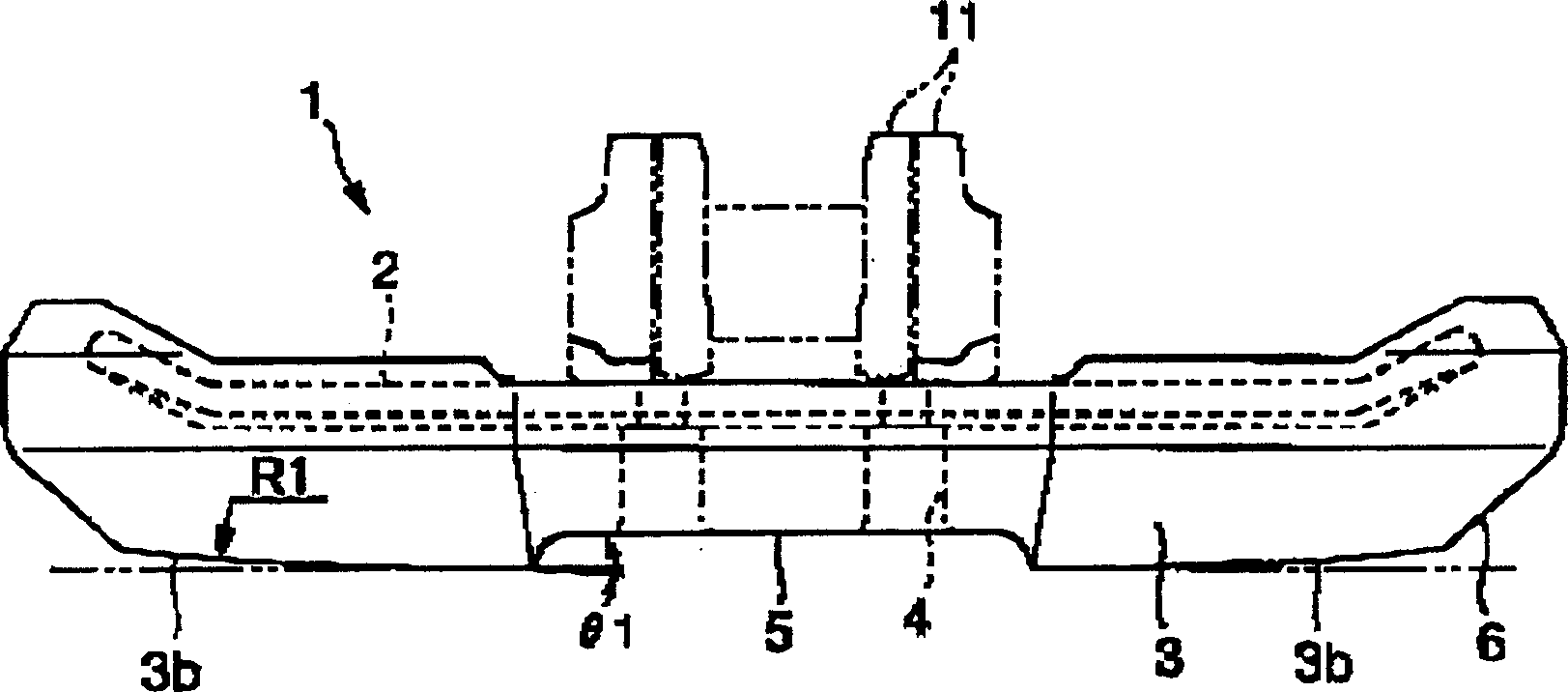

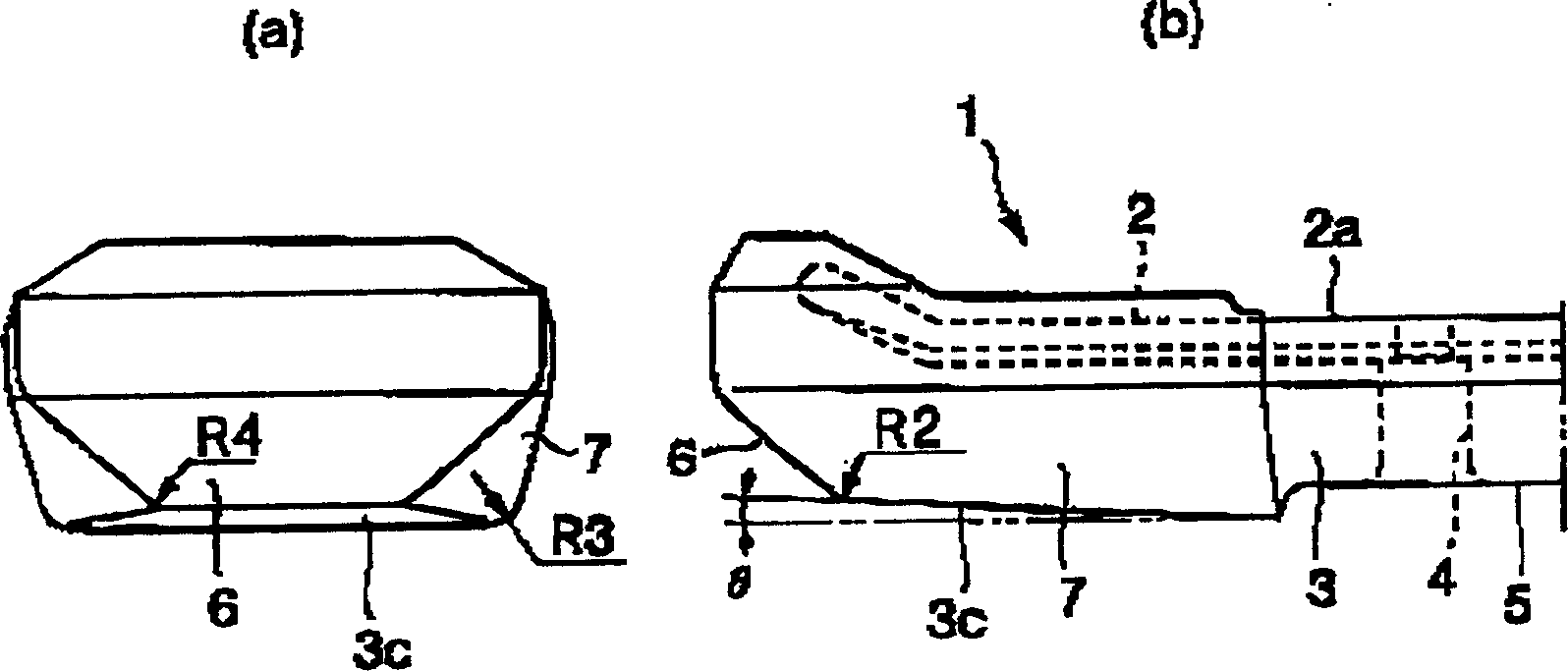

[0022] figure 1 , is a side view of the elastic body track shoe of Embodiment 1. exist figure 1 Among them, an elastomer track shoe 1 has a core bone 2 and an elastic body 3 such as rubber vulcanized around the core bone 2 . A concave portion 5 is provided on the ground contact surface side of the central portion of the elastic body 3 in the track width direction (left-right direction in the figure). In the concave portion 5, there is a hole that penetrates the elastic body 3 and the core bar 2 from the ground contact surface to the non-ground contact surface. Left and right mounting holes 4, 4. The central portion of the core bar 2 on the side of the non-grounding surface is in a state exposed from the elastic body 3, and the exposed surface of each core bar 2 becomes a bolt (not shown) inserted into the left and right mounting holes 4, 4. , is mounted on the mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com