Underground cable and wire laying robot

A technology for underground cables and robots, which is applied to cable laying equipment, manipulators, motor vehicles, etc., and can solve problems such as incorrect calculation of the actual height of sand, gravel and soil, and occlusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

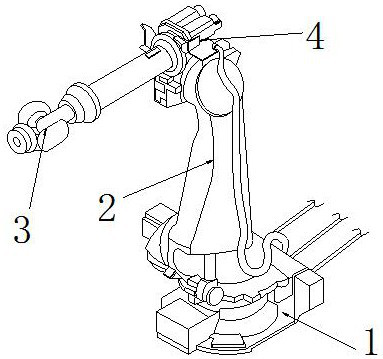

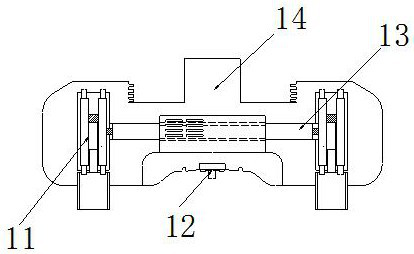

[0027] as attached figure 1 to attach Figure 4 Shown:

[0028] The present invention provides an underground cable and wire laying robot, the structure of which includes a mobile device 1, a support column 2, a camera 3, and a central control 4. The mobile device 1 is embedded and installed directly under the support column 2, and the support column 2 The central control 4 is installed on the upper surface by welding, and the camera 3 is inlaid and mounted on the left end surface of the central control 4; the mobile device 1 includes a support device 11, an infrared scanner 12, a power rod 13, and a support shaft 14. The support device 11 is symmetrically installed on the left and right sides of the power rod 13, the infrared scanner 12 is embedded and installed directly below the support shaft 14, and the outer side of the power rod 13 is embedded with the infrared scanner 12. The support shaft 14 is threadedly connected to the lower end surface of the support column 2, an...

Embodiment 2

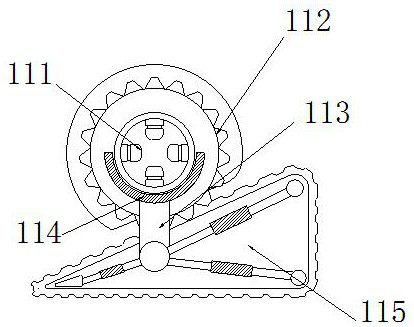

[0034] as attached Figure 4 to attach Figure 8 Shown:

[0035]Wherein, the pressure dividing mechanism 115 includes a crawler belt 5a, a movable rod 5b, a connecting shaft 5c, a tension plate 5d, and a second connecting shaft 5e. Embedded and installed on the left and right sides of the connecting shaft 5c, the upper end surface of the tension plate 5d is embedded with the second connecting shaft 5e, and the upper end surface of the second connecting shaft 5e is connected to the connecting rod 113 by welding. There are six shafts 5c, and the distribution angle is consistent with the outline of the outer end of the pressure dividing mechanism 115. Using the segmented design, when the upper end is under pressure, the connecting shaft 5c can shrink and reduce pressure, effectively reducing the concentration of pressure.

[0036] The connecting shaft 5c includes a threaded connection end 5c1, a spring 5c2, an interaction mechanism 5c3, and a fixed block 5c4. The thread connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com