Process design method for plate rolling

A process design and plate technology, applied in the field of plate rolling, can solve the problems of low efficiency and low calculation accuracy in manual calculation of slab specifications and weight, achieve unified and reliable calculation data sources, overcome uncertainties, improve efficiency and The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to enable those skilled in the technical field to which the application belongs to understand the application more clearly, the technical solutions of the application will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

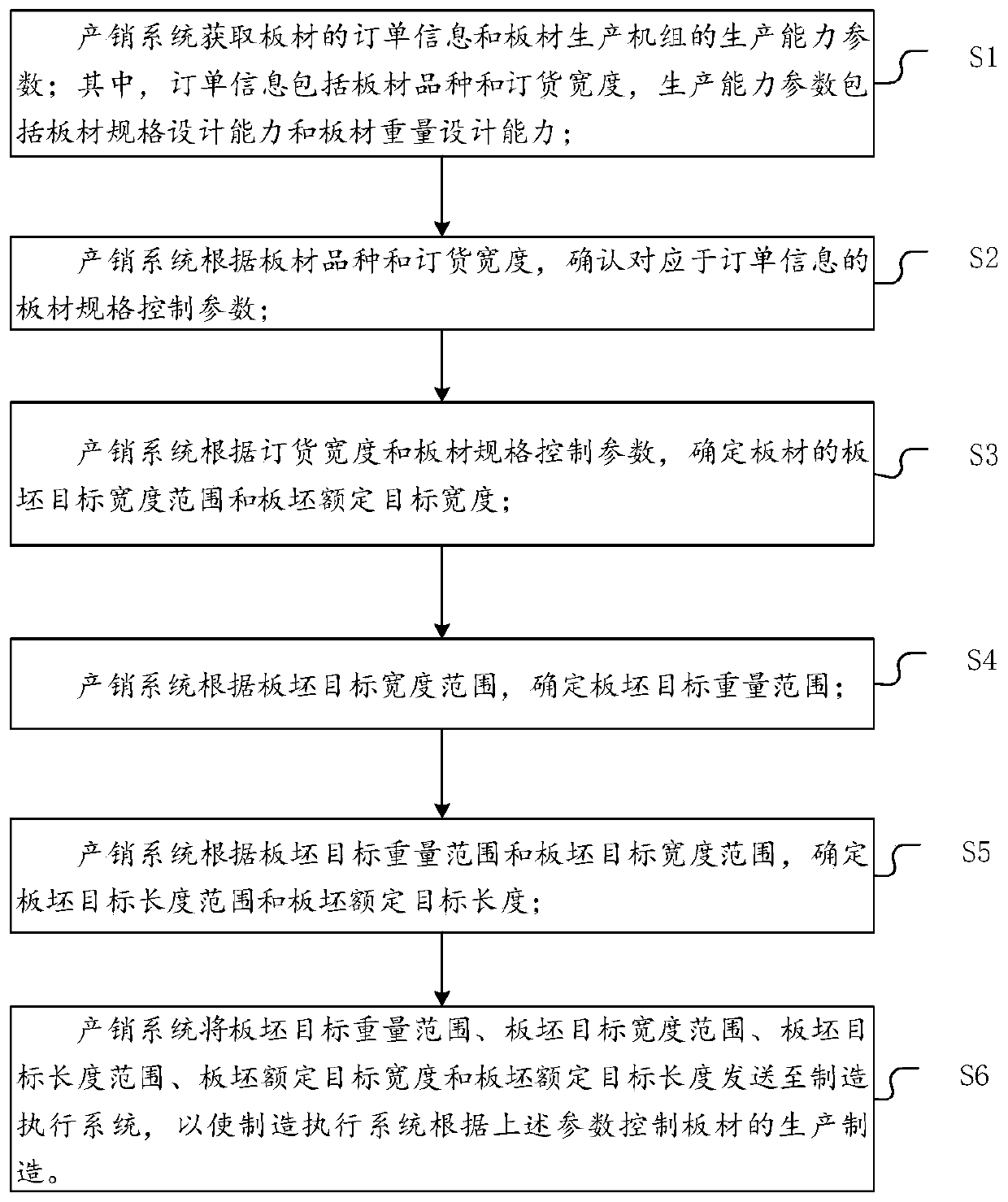

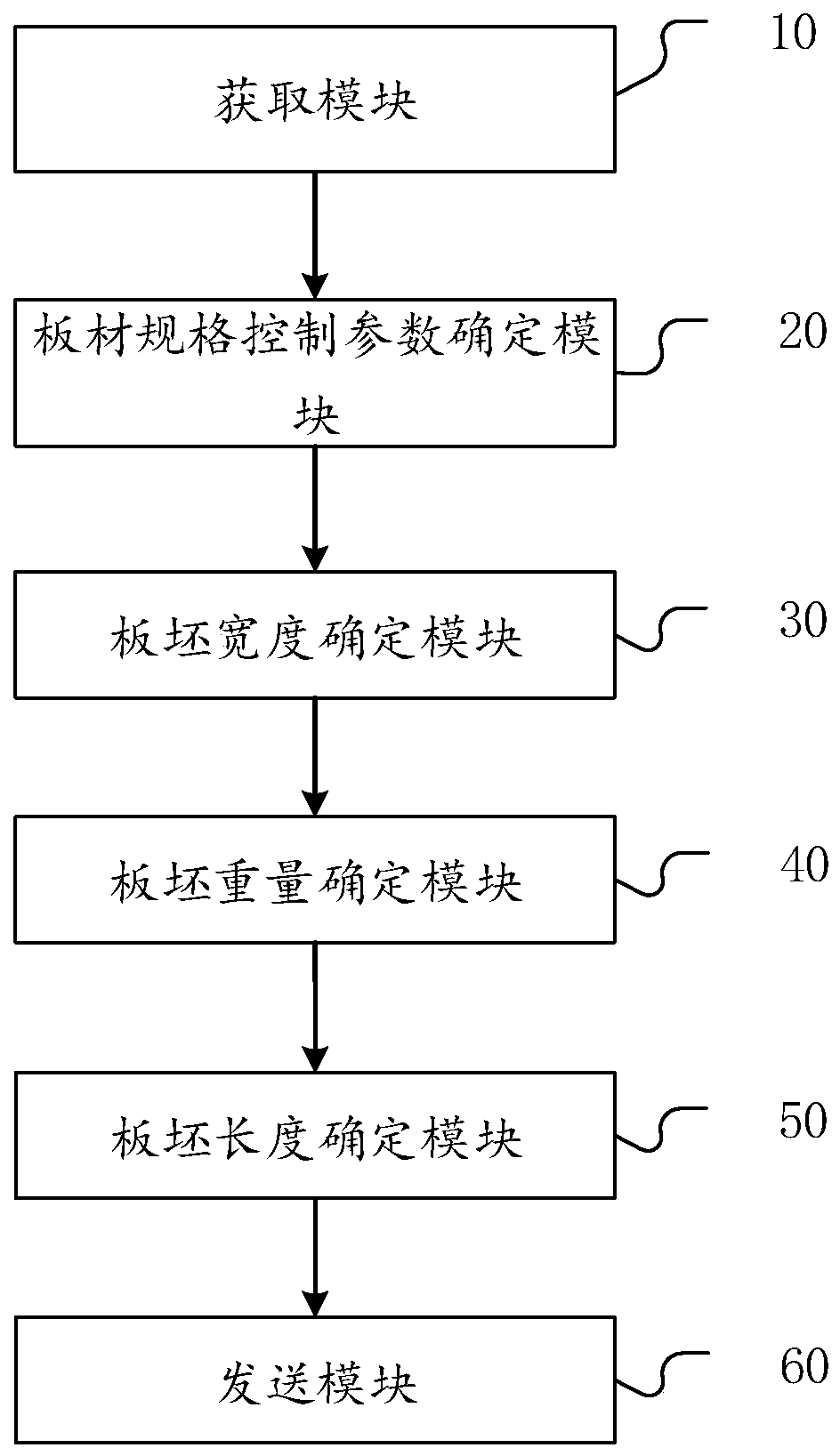

[0053] In order to solve the low calculation efficiency and accuracy caused by relying on experience to manually calculate the slab specifications and weight, it is easy to cause the estimated slabs to fail to meet the order requirements, resulting in a backlog of inventory, or forcing the order to be cut or transferred in the downstream process. Spot sales and other issues. In an optional embodiment, the inventor, such as figure 1 As shown, a process design method for plate rolling that obtains relevant parameters through programming in the production and sales system and accurately calculates the specifications and weight of slabs according to the order information is proposed, which c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com