Method for making modular energy-absorbing assembly

An energy absorption component, energy absorption technology, used in vehicle components, household components, applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

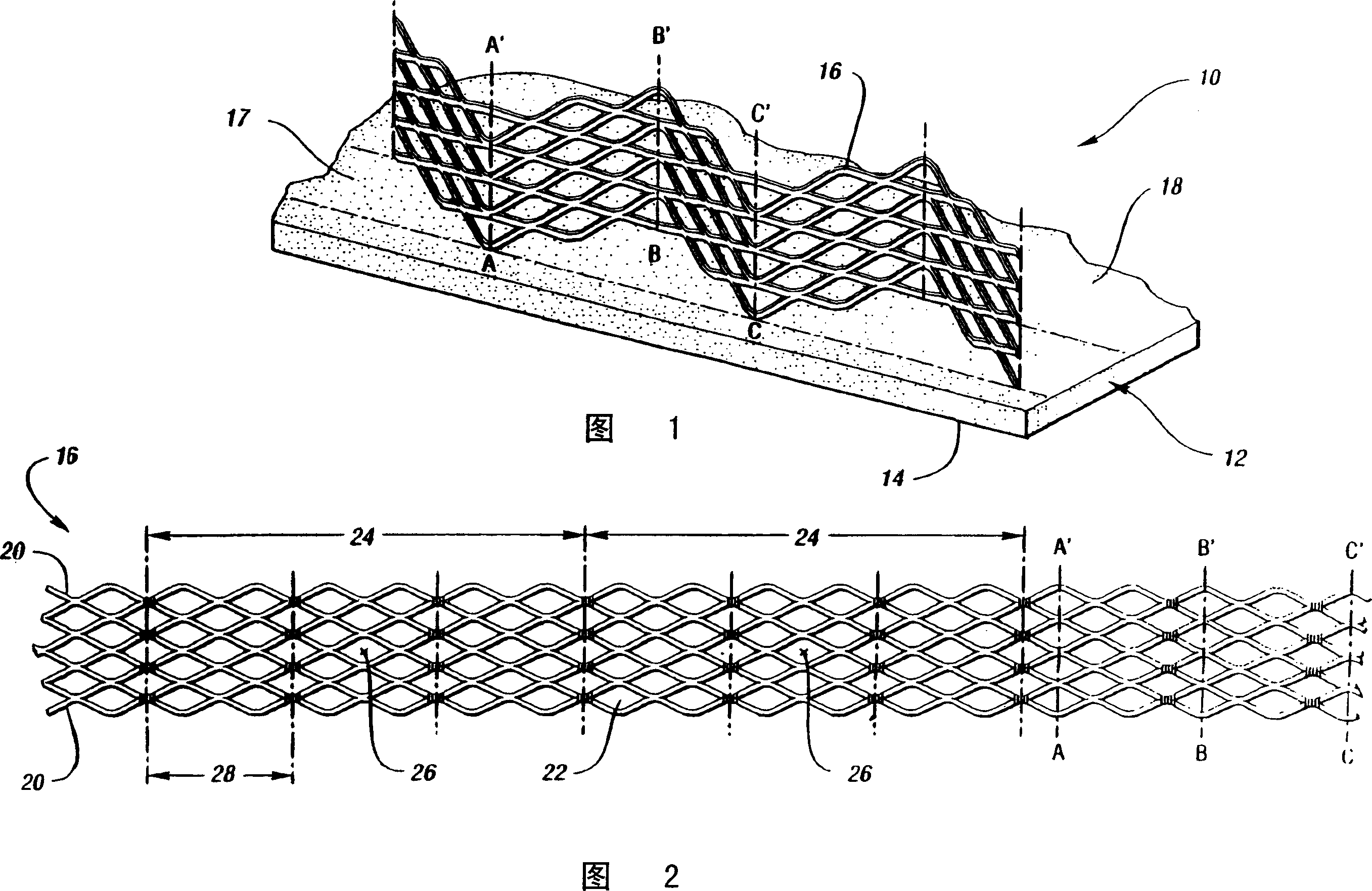

[0036] Before disclosing the manufacturing process steps implemented in accordance with the principles of the present invention, various products and their quality characteristics are first disclosed.

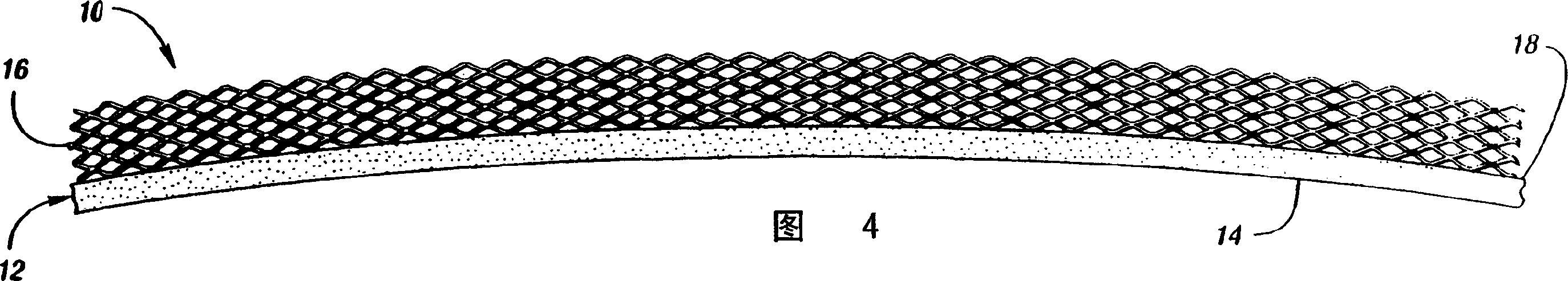

[0037] Referring first to Figure 1, there is shown an energy absorbing assembly 10 made in accordance with the steps of the present invention for decelerating an object (not shown) impinging on the assembly. In the preferred embodiment, the assembly 10 includes an accident component 12 having an accident surface 14 in contact with an impacting object. At least one energy absorbing member 16 is connected to a connection area 17 of the opposite face 18 of the accident member 12 for receiving the deformation of the assembly 10 .

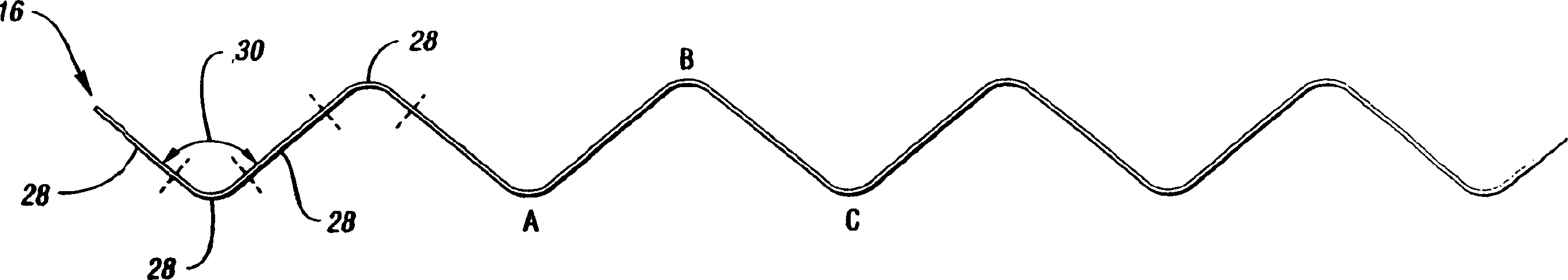

[0038] Referring now to FIG. 2 , each energy absorbing member 16 includes a grid structure of interconnected strands 20 of material, such as expanded metal, that provide the assembly 10 with unique energy absorbing properties. The energy absorbing membe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com