Intensifying fabricating methods for finishing operation of parts

A processing method and finishing technology, which is applied in the field of parts finishing and strengthening processing technology, can solve problems such as low processing accuracy, low production efficiency, and danger, so as to improve dimensional accuracy and shape accuracy, correct shape and position errors, and improve production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

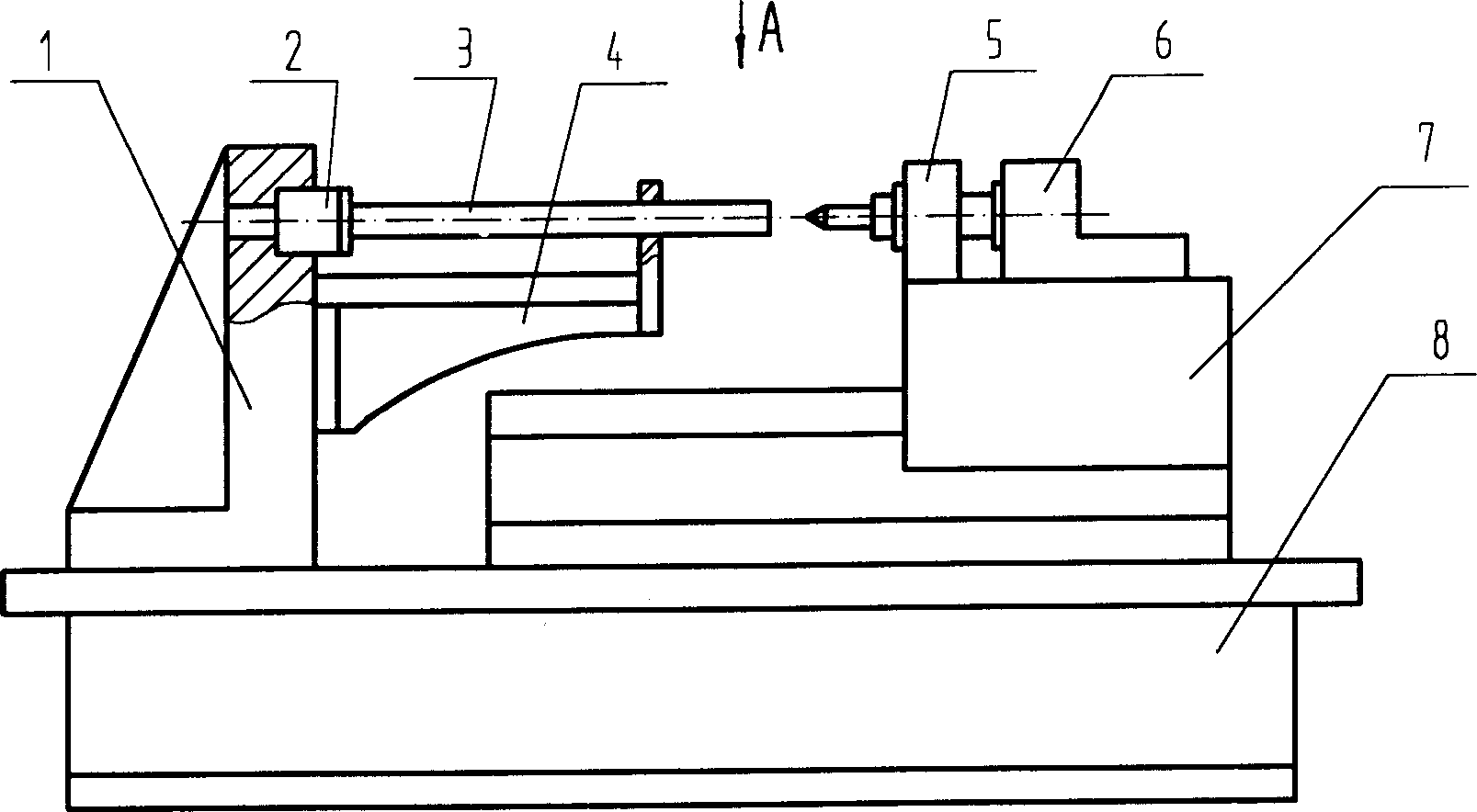

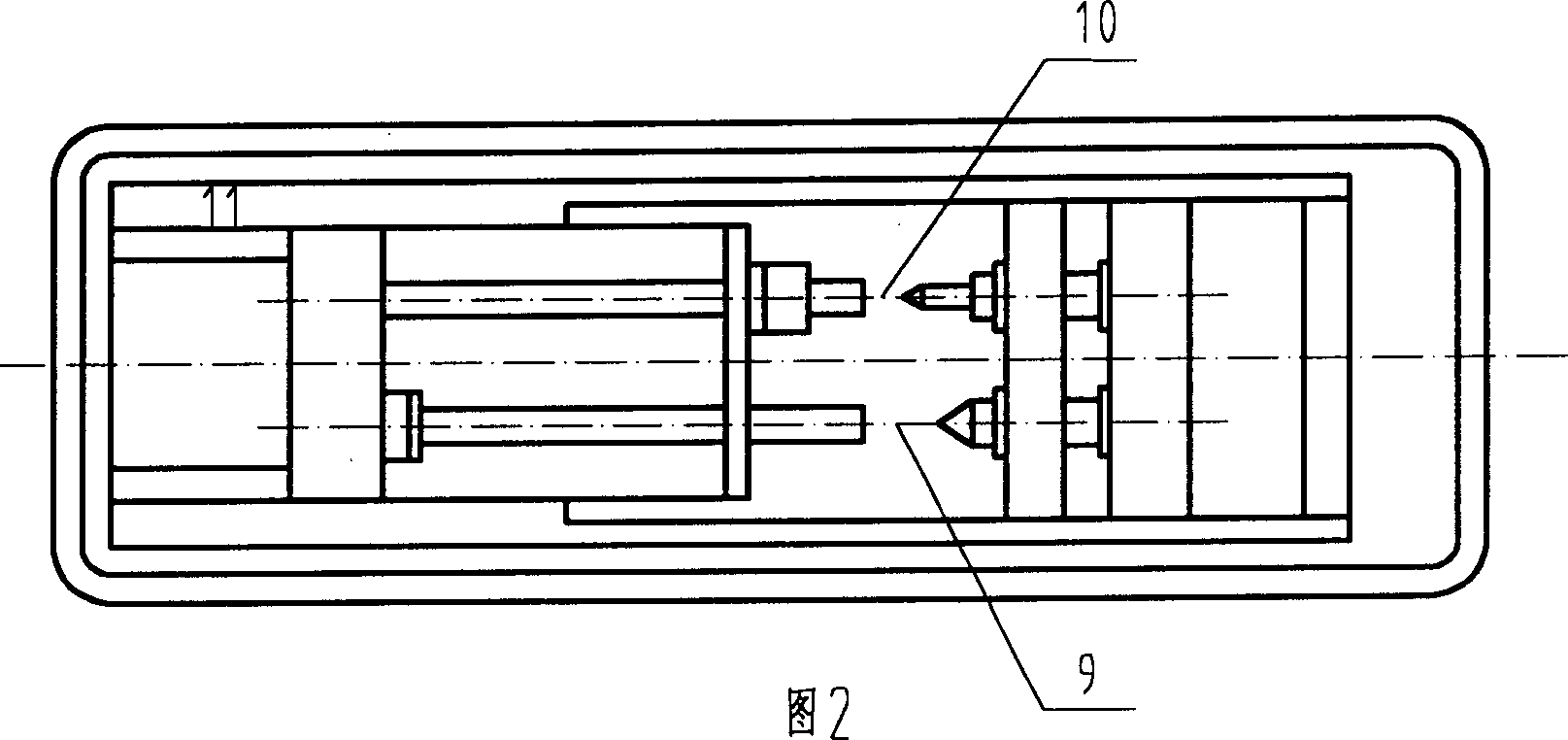

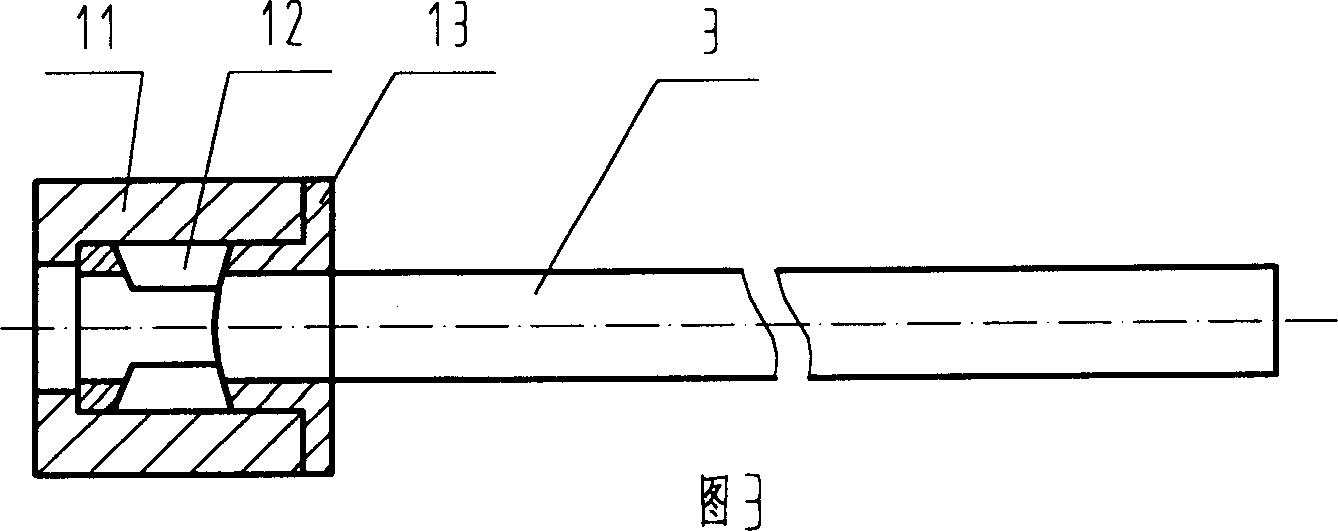

[0017] Accompanying drawing has provided structural representation of the present invention, press figure 1 And the structural design of Fig. 2 manufactures a special finishing hydraulic press. The hydraulic press consists of a base 8, a hydraulic sliding table 7, a top mechanism 5, a bracket 4, a fixed seat 6 and a curved plate 1. The curved plate 1 and the hydraulic sliding table 7 are installed on the base 8, and the fixed seat 6 is installed on the hydraulic sliding table 7. , which is equipped with two top mechanisms 5 for pressing in and out parts, and the bracket 4 is installed on the bent plate 1, and is provided with two stations for supporting parts. Design and manufacture a set of finishing mold 2 according to the structural design of Fig. 3, be made up of finishing mold 11, finishing pin 12 and finishing cover 13, finishing cover 13 is used for fixing finishing pin 12. The cavity of the finishing die is designed as a group of multiple finishing dies of different s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com