Permanent magnet for motor

A technology of permanent magnets and motors, which is applied in the direction of permanent magnets, inorganic material magnetism, and static parts of magnetic circuits, etc., and can solve problems such as insufficient magnetic field and small torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

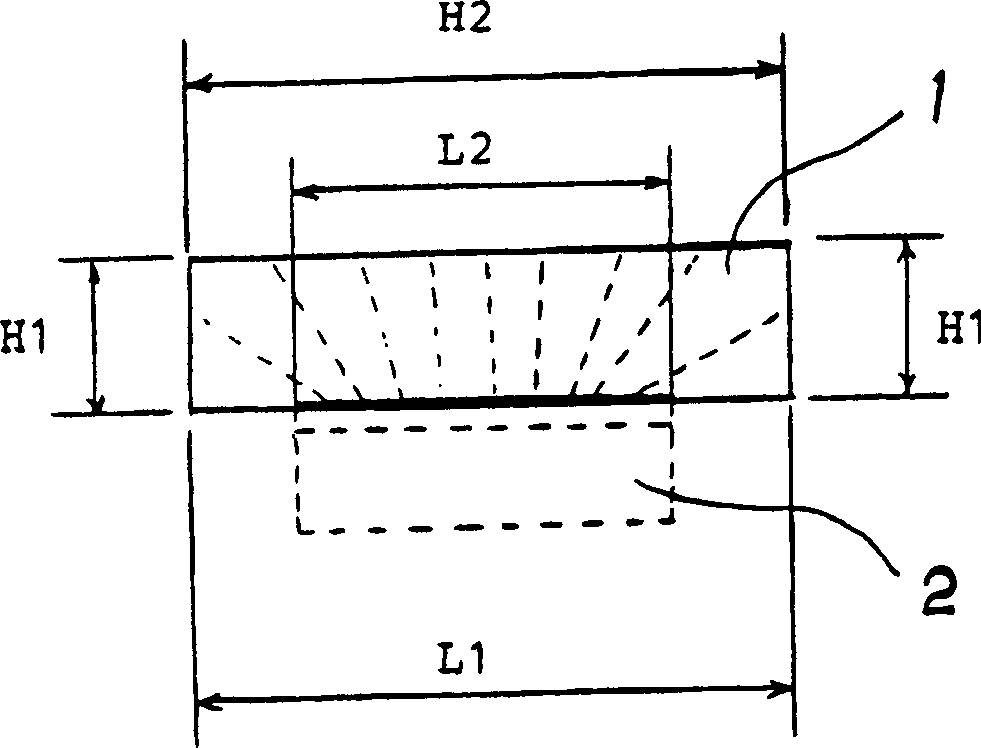

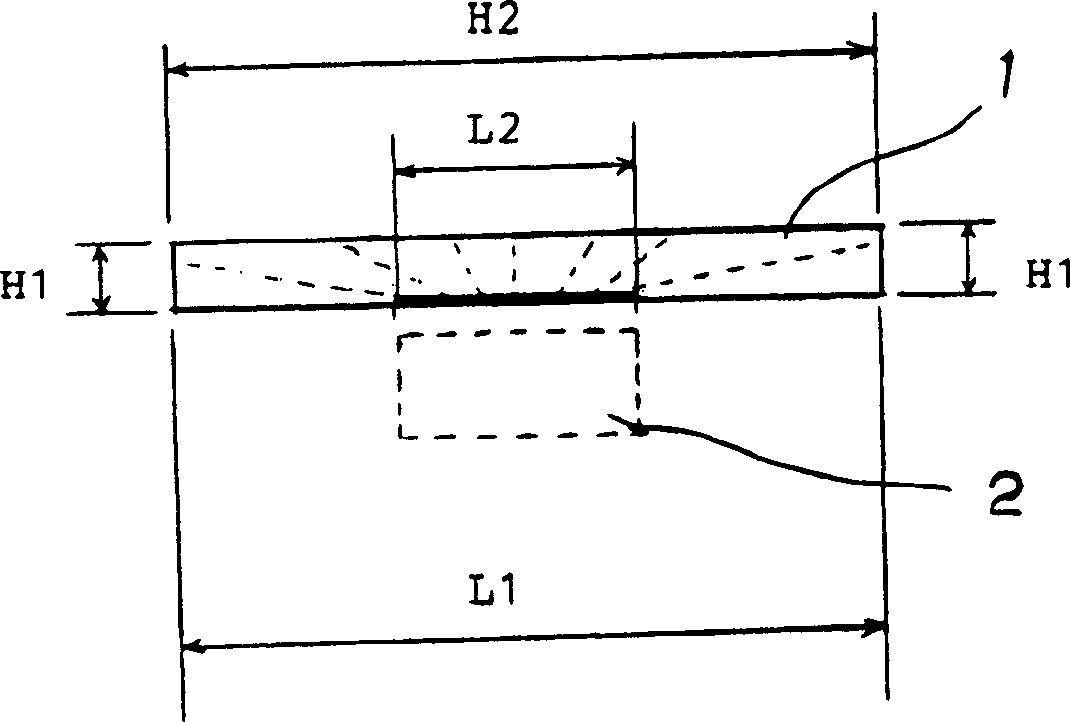

[0082] Example 1, Comparative Examples 1-2

[0083] Using the above-mentioned ratio and forming conditions, a ring-shaped motor magnet is manufactured, and the magnet is used as a stator to assemble as Picture 10 or Figure 8 The performance of the motor shown (gap between stator and rotor = 0.2 mm) was evaluated. The results are shown in Table 1. As can be seen from Table 1, Example 1 is 1.1 times the gap magnetic field of Comparative Example 1. In addition, since the L2 / L1 of Comparative Example 2 is small, the gap magnetic field is 0.9 times that of Comparative Example 1.

[0084] In addition, for Comparative Examples 1 to 2, in Picture 10 (B), such as Figure 14 As shown, an annular magnet oriented parallel to the active surface from the non-acting surface is used.

[0085] Example 1

[0086] *in Picture 10 (B), such as Figure 14 As shown, the active surface is oriented parallel from the non-active surface.

Embodiment 2~3

[0088] Except for the changes shown in Table 2, the same operations as in Example 1 were performed. The results are shown in Table 2. For comparison, the results of Example 1 are also listed in Table 2. As can be seen from Table 2, Examples 2 to 3 increase to 1.06 times and 1.15 times of the gap magnetic field of the aforementioned Comparative Example 1.

[0089] Example 1

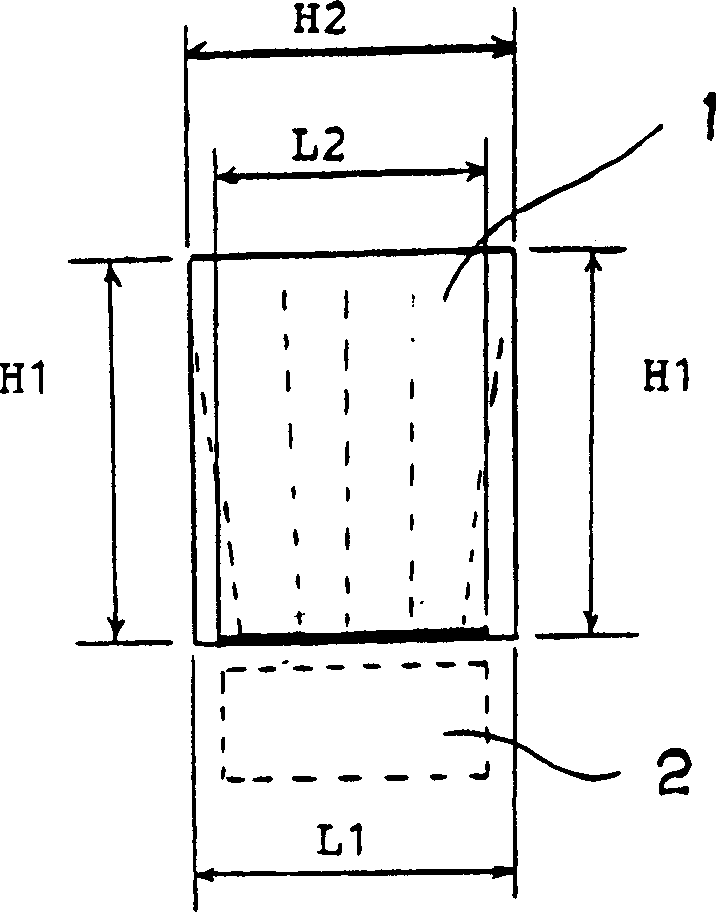

Embodiment 4~6、 comparative example 3

[0091] Except for the changes shown in Table 3, the same operations as in Example 1 were performed. The results are shown in Table 3. As can be seen from Table 3, in Examples 4 to 6, the gap magnetic field increases to 1.07 times, 1.04 times, and 1.10 times that of Comparative Example 3.

[0092] In addition, for Comparative Example 3, Figure 8 (B), such as Figure 14 As shown, a tile-shaped magnet oriented parallel to the active surface from the non-active surface is used.

[0093] Example 4

[0094] *in Figure 8 In, such as Figure 14 As shown, the active surface is oriented parallel from the non-active surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com