Ink box

A technology of ink cartridges and ink chambers, used in printing and other directions, can solve the problems of impact damage to the print head, contamination of the printer and printing media, etc., and achieve the effect of avoiding ink leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

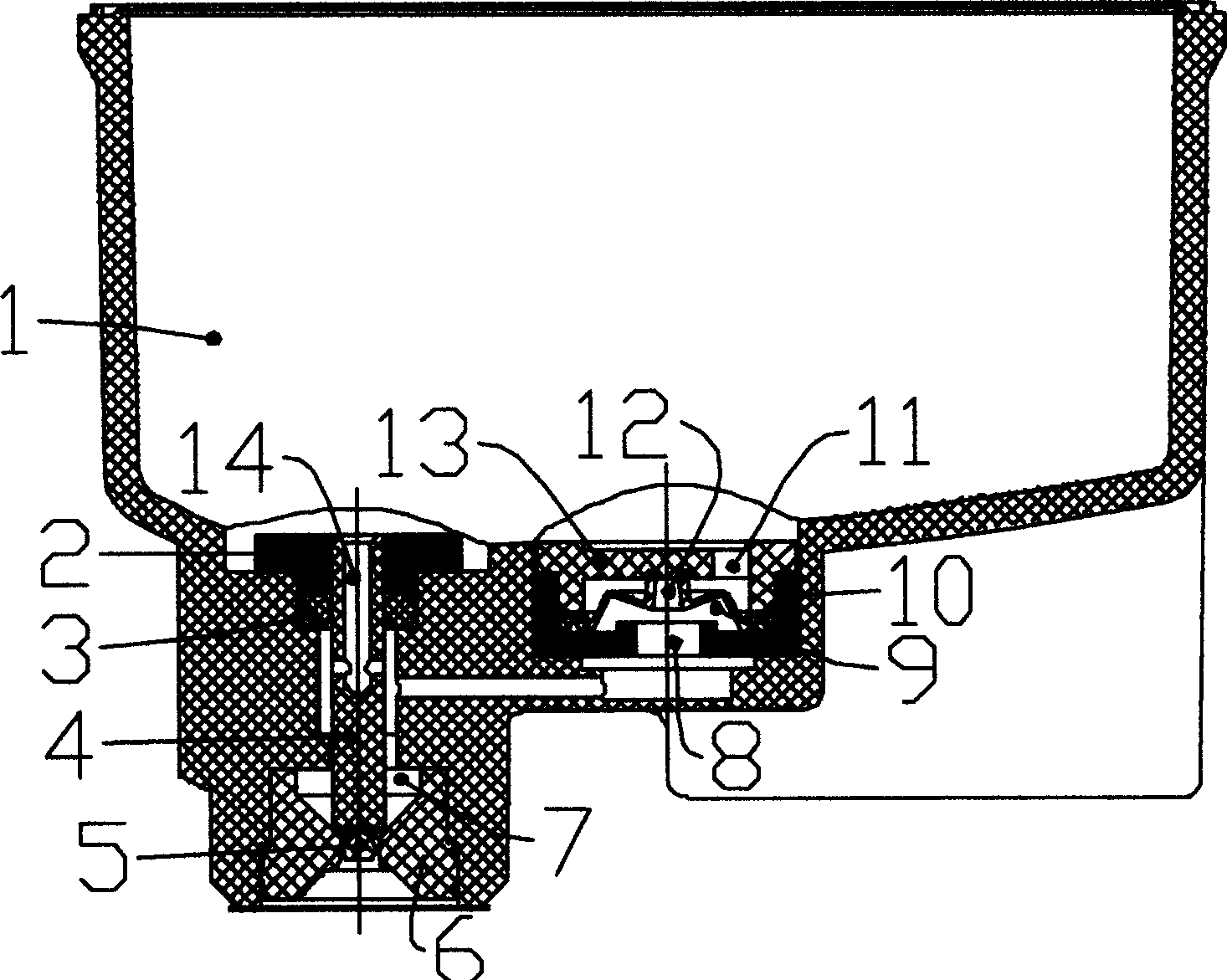

[0028] see figure 1 , figure 2 , there is a seal 6 built into the ink outlet, the stopper 5 is connected with the seal 6 through a thin annular film, and there is a one-way valve between the ink chamber 1 and the ink outlet, and the one-way valve has a through hole The bottom cover 10 of 8, the spool 9 with the central through hole 12 and the gland 13 with the through hole 11 are combined, and the spool 9 made of elastic material relies on its own elasticity to make the valve core with the central through hole The head of 12 is pressed tightly on the valve face of gland 13. The ink supply chamber 7 is the space between the valve surface and the stopper 5 . There is a prosthesis 4 on the axis where the ink supply needle 15 enters, and the prosthesis 4 is in clearance fit with the bush 2 fixed on the box body, and the sealing ring 3 ensures that when the prosthesis 4 moves axially relative to the bush 2, both The tightness between them is to ensure positive and equal volume...

no. 2 example

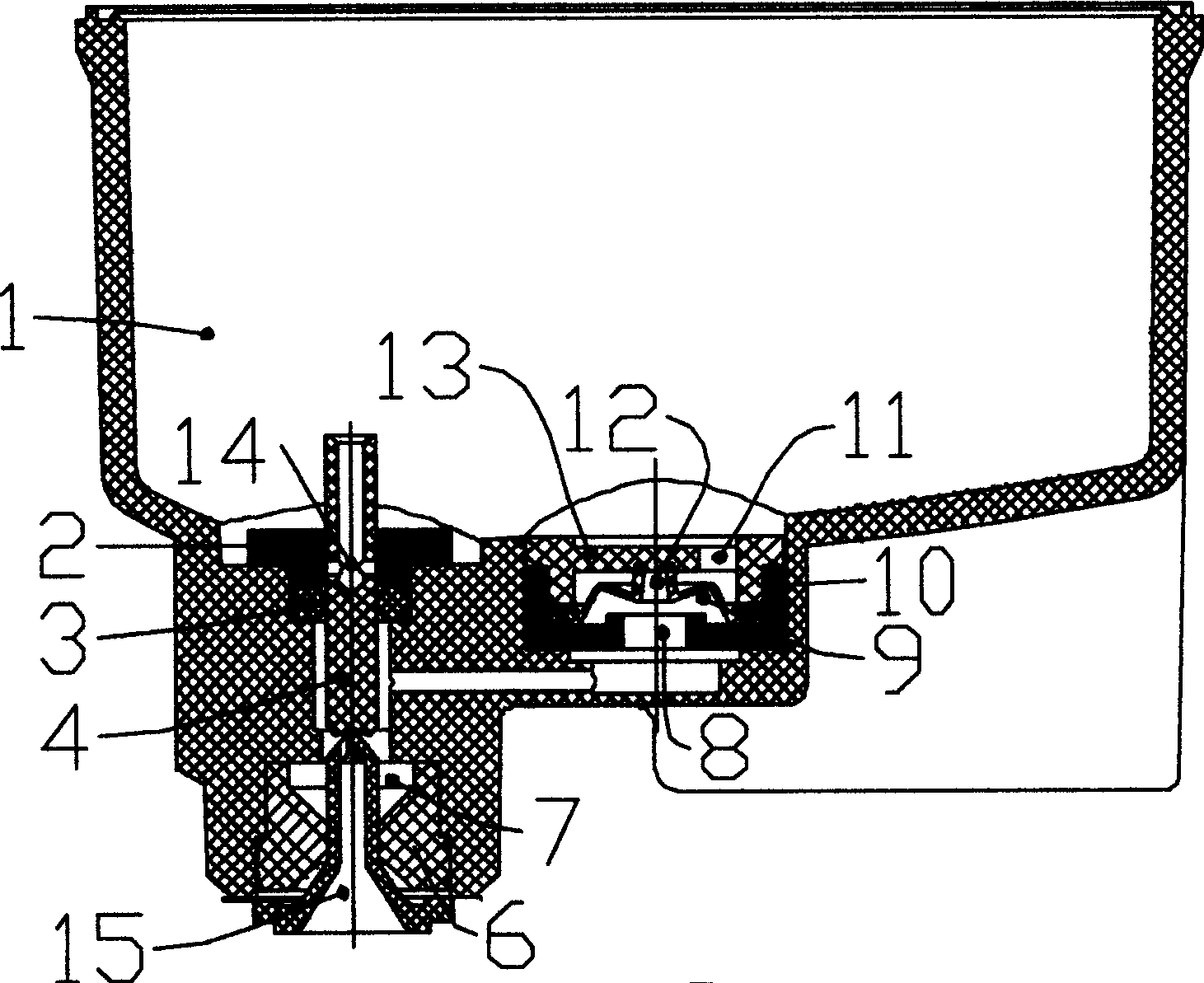

[0030] See Figure 3, Figure 4 , there is a seal 6 built into the ink outlet. Unlike the previous example, this example cancels the stopper. As can be seen from the figure, its function can be completed by the end of the prosthesis 4 located in the seal 6, and the outer end of the ink outlet There is a sealing film 16, and there is a one-way valve between the ink chamber 1 and the ink outlet. The gland 13 is combined, and the valve core 9 made of elastic material has the elasticity that the valve core 9 has by itself, so that the head with the central through hole 12 is pressed tightly on the valve surface of the gland 13. The ink supply chamber 7 is a space between the valve surface and the sealing member 6 . There is a prosthesis 4 on the axis where the ink supply needle 15 enters, and the prosthesis 4 is in clearance fit with the bush 2 fixed on the box body, and the sealing ring 3 ensures that when the prosthesis 4 moves axially relative to the bush 2, both The tightness...

no. 3 example

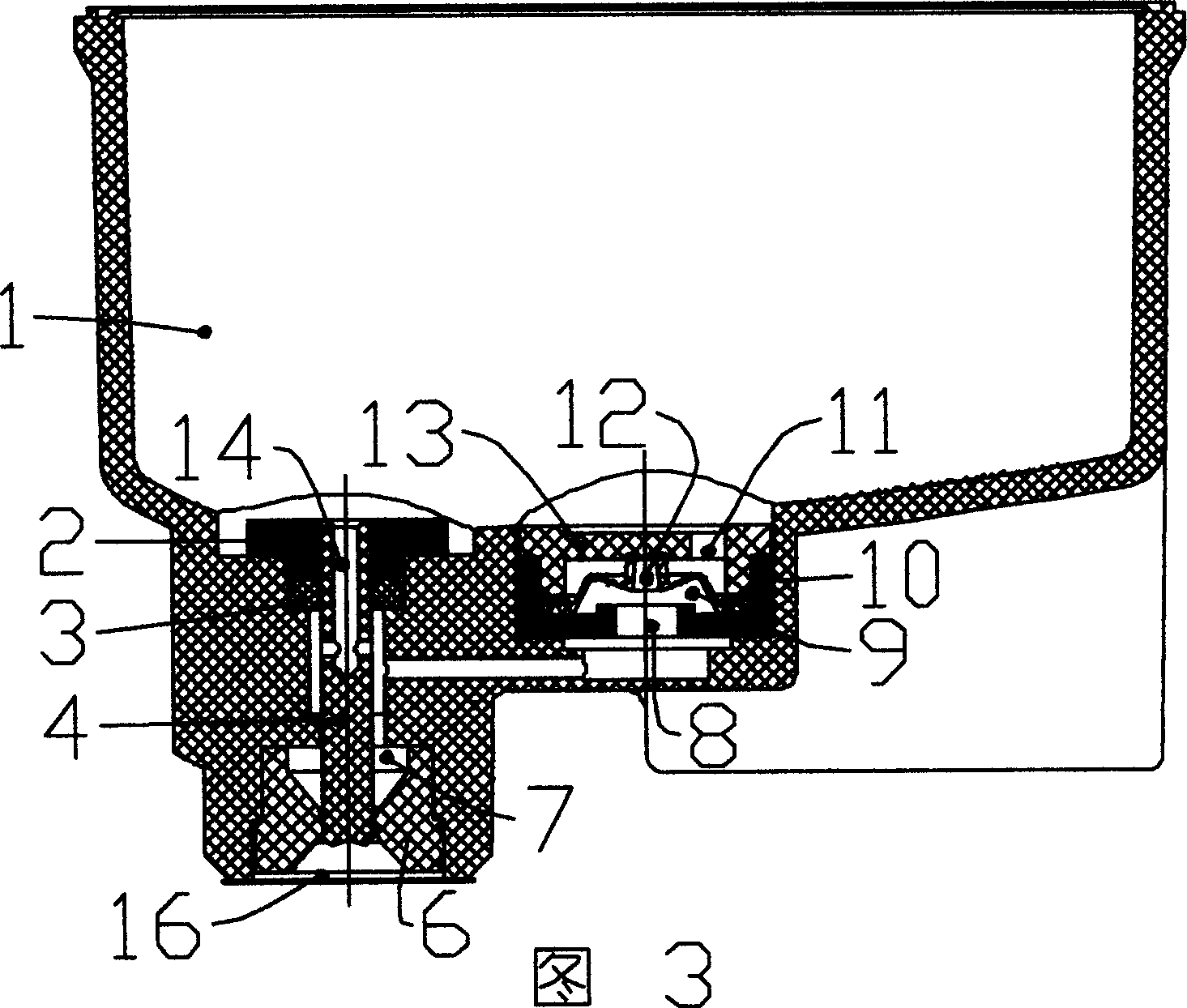

[0032] Referring to Fig. 5, there is a seal 6 built into the ink outlet, the stopper 5 is connected with the seal 6 through a thin annular film, and there is a one-way valve between the ink chamber 1 and the ink outlet, and the one-way valve is controlled by a The bottom cover 10 that has through hole 8, the spool 9 that has center through hole 12 and the gland 13 that has through hole 11 are combined to form, and the spool 9 that elastic material is made relies on the elasticity that self has, makes with The head of the central through hole 12 is tightly pressed against the valve surface of the gland 13 . The ink supply chamber 7 is a space between the valve surface and the sealing member 6 . There is a pressure relief passage between the ink chamber 1 and the ink supply chamber 7, and a one-way pressure relief valve 17 for pressure relief is reversely arranged in the passage, that is, the valve only works when the pressure of the ink supply chamber 7 reaches or exceeds the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com