Injection molder

A technology for injection molding and forming machines, which is applied in the field of injection molding machines, and can solve problems such as deflection of fixed templates, lack of connecting rods, skewing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

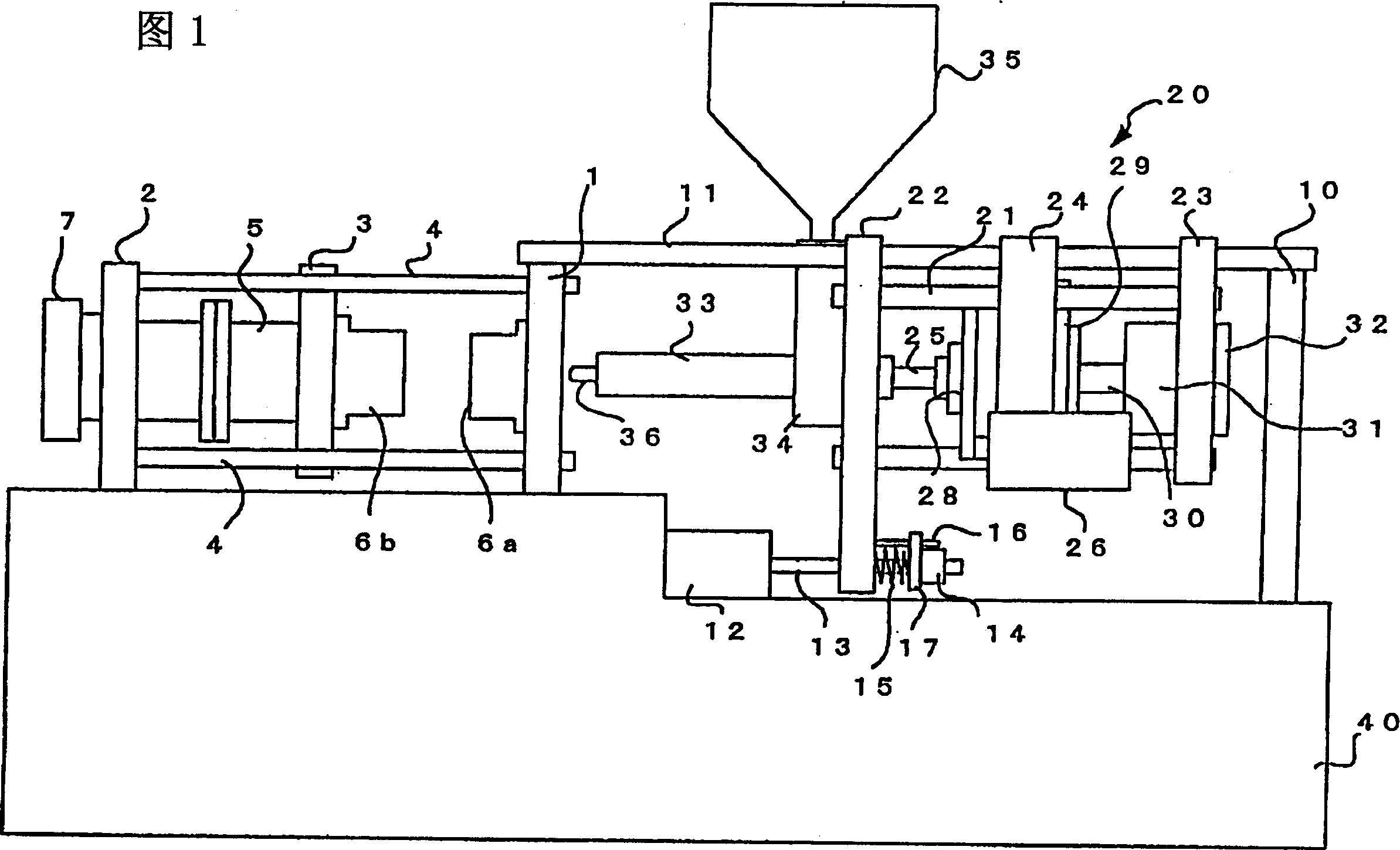

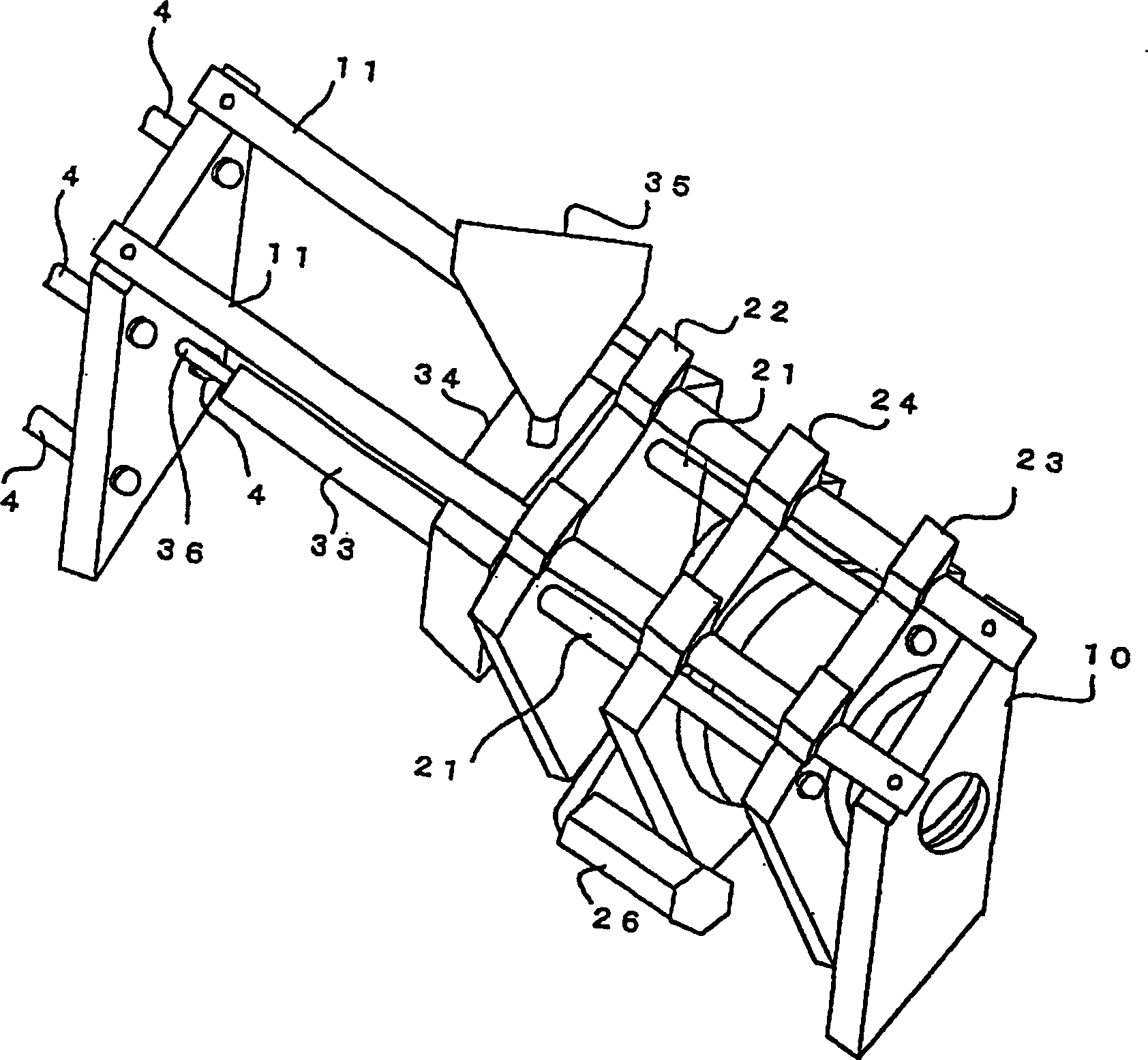

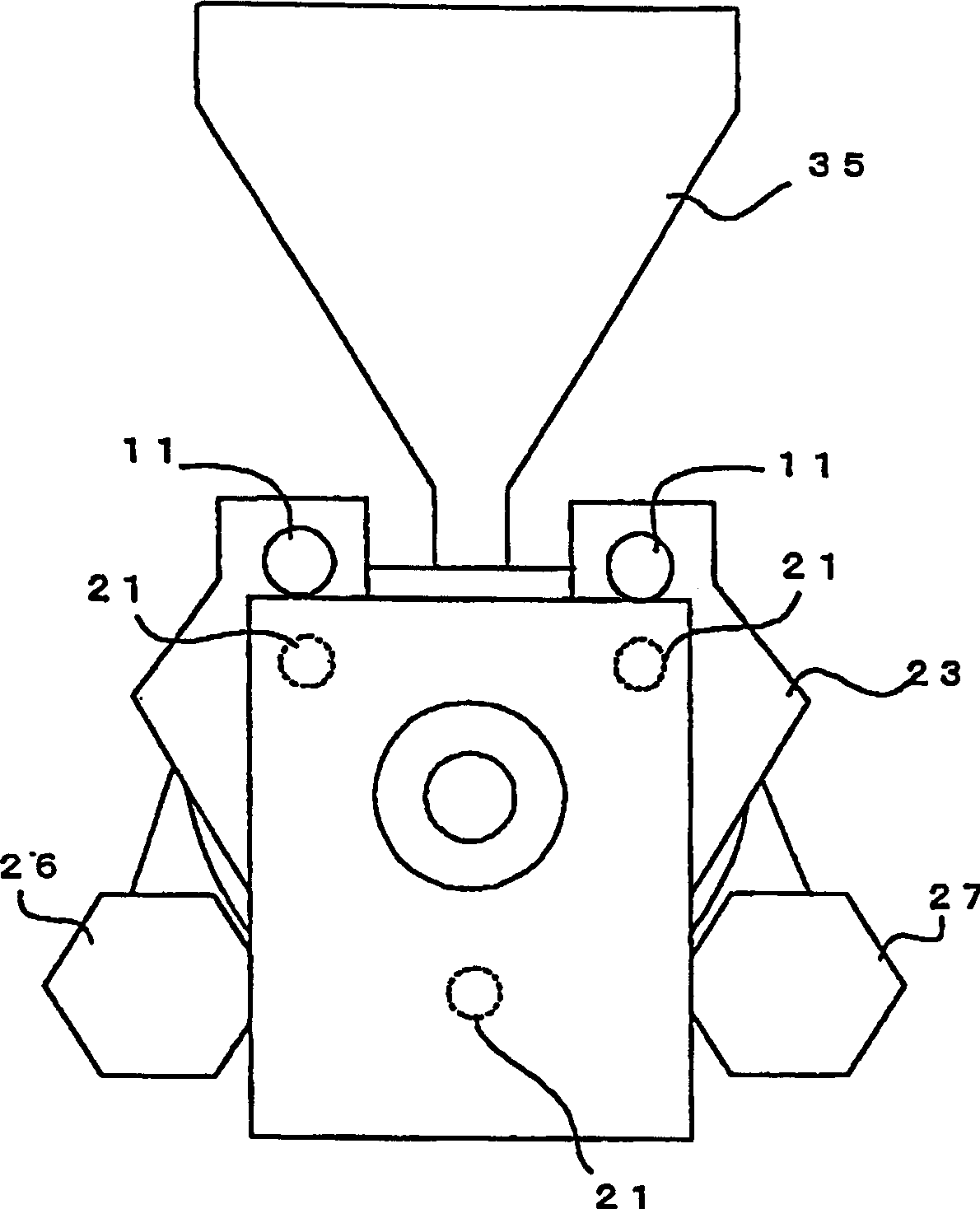

[0020] Fig. 1 is a front view of an injection molding machine according to an embodiment of the present invention. figure 2 It is a perspective view of the injection device side. image 3 It is a side view seen from the right side of Figure 1. A fixed template 1 is fixed to the machine base 40, and a mold clamping mechanism is arranged on one side of the fixed template 1. That is, the back platen 2 forming a part of the mold clamping mechanism is installed above the machine base 40, and four connecting rods 4 are installed between the back platen 2 and the fixed template 1. Between the back platen 2 and the fixed template 1, the movable template 3 is slidably mounted on the four connecting rods 4, and guided by the connecting rods 4, it can move in the left-right direction in FIG. 1. A clamping mechanism 5 is arranged between the back platen 2 and the movable template 3. On the fixed template 1, a fixed side metal mold 6 a is installed, and a movable side metal mold 6 b is instal...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap