Injection apparatus and molding method in injection molding machine

A technology of injection molding machine and injection device, which is applied in the field of molding, can solve problems such as insufficient filling and low-pressure molding, and achieve the effects of suppressing defects, preventing insufficient filling, and easy filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

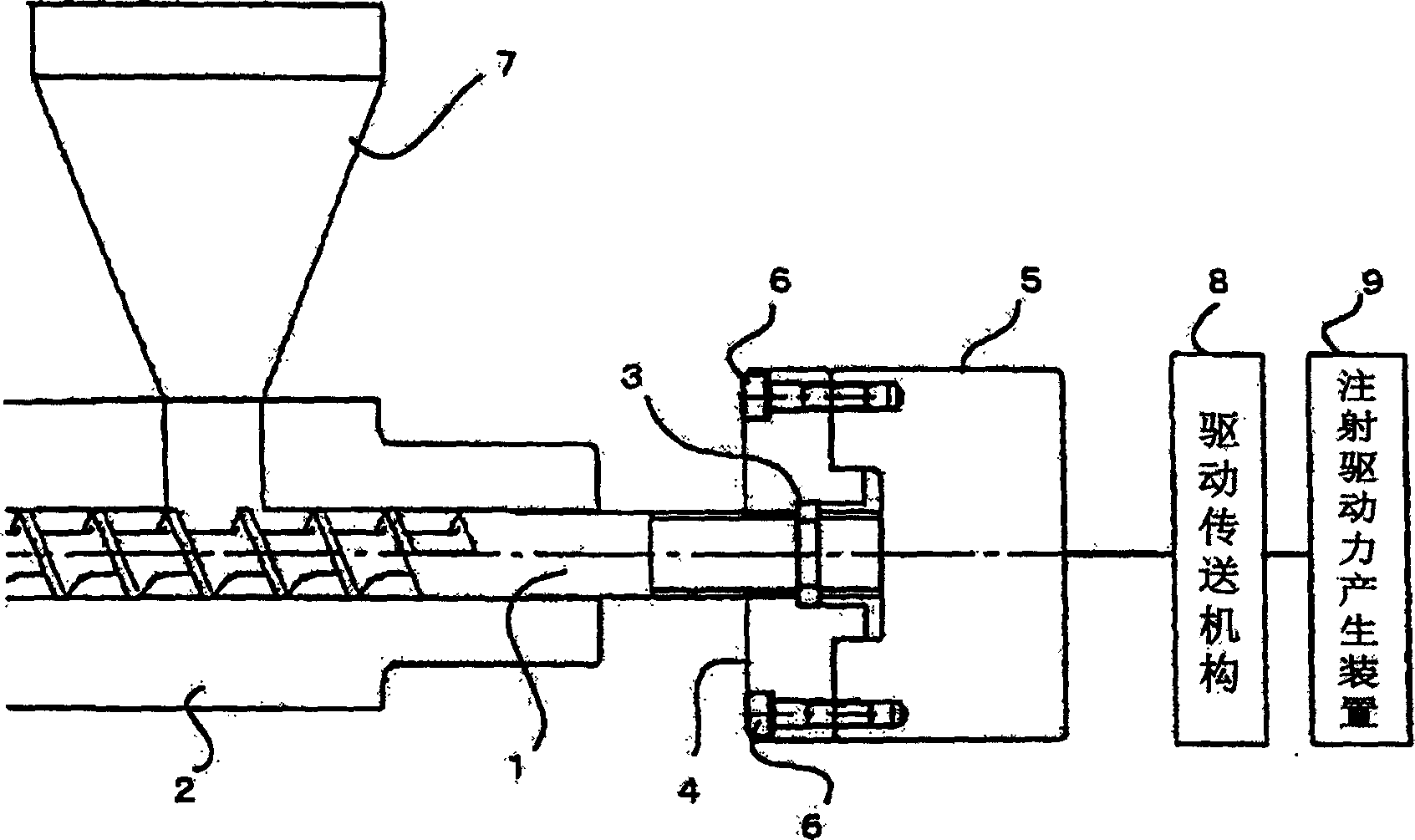

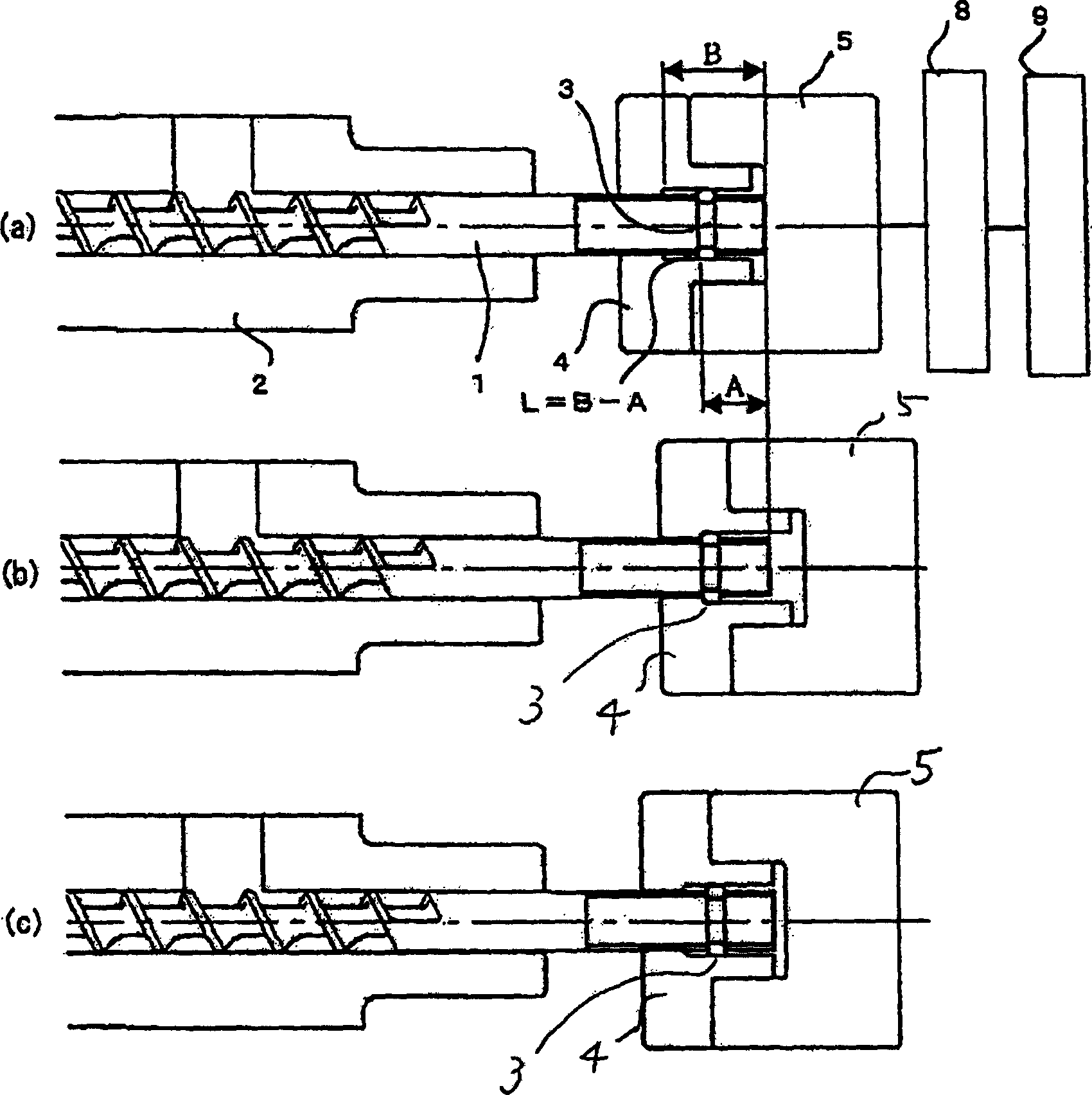

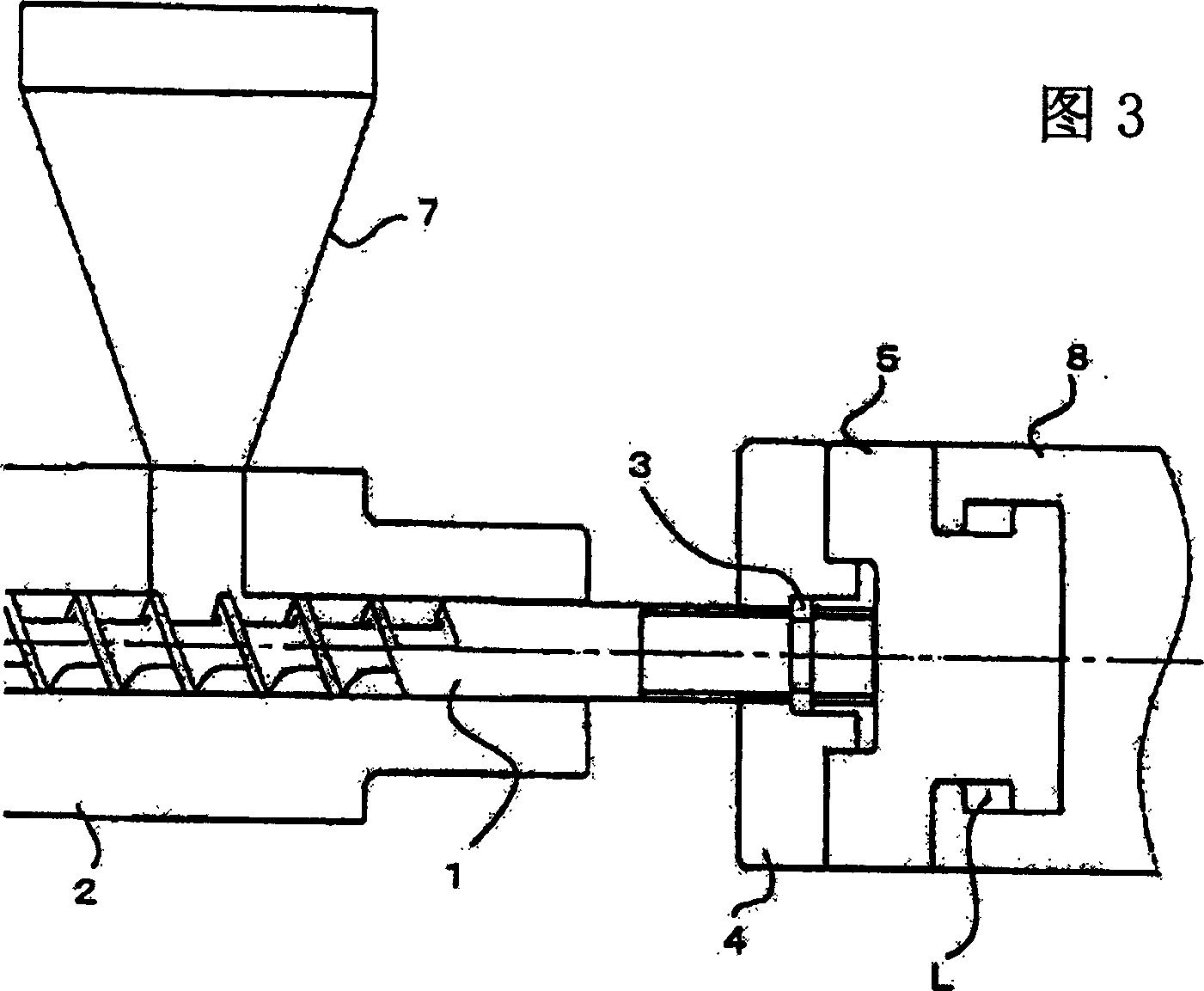

[0024] figure 2 It is a schematic diagram of the connection relationship between the screw and the screw mounting part in the first embodiment of the present invention. and, with figure 1 The same elements of the shown prior art examples are denoted by the same symbols. And, with figure 1 The original example shown is the same, the bushing 4 and the sleeve 5 are secured by bolts, figure 2 Bolts are omitted.

[0025] In this first embodiment, a dead zone in which the two can move relative to each other is set between the screw 1 and the screw mounting part composed of the sleeve 5 and the bushing 4, and figure 1 The conventional example shown is different. That is, if figure 2 As shown, the stop ring 3 provided on the screw 1 will not contact the stop ring restraining face of the bush 4 even when the terminal surface of the screw 1 is in contact with the face of the sleeve 5 . That is to say, the stop ring 3 will not be squeezed by the sleeve 5 and the bush 4 . The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com