Permanent magnet vacuum circuit breaker

A permanent magnet vacuum and circuit breaker technology, applied in the direction of high-voltage air circuit breakers, circuits, electrical components, etc., can solve the development trend that cannot adapt to the miniaturization of inflatable cabinets, there are many movement transmission links of the motion axis, and the overall structure is complex and large, etc. problems, to achieve the effect of improving assembly efficiency and process effect, ensuring reliability and operating stability, and ensuring transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

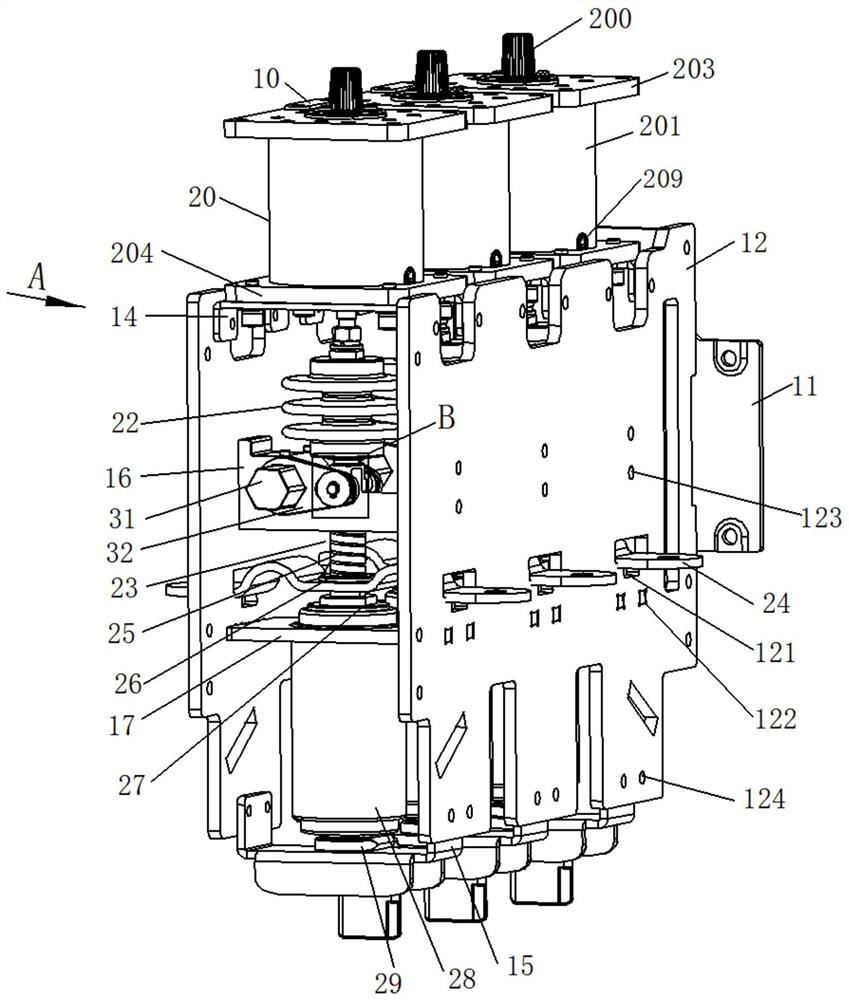

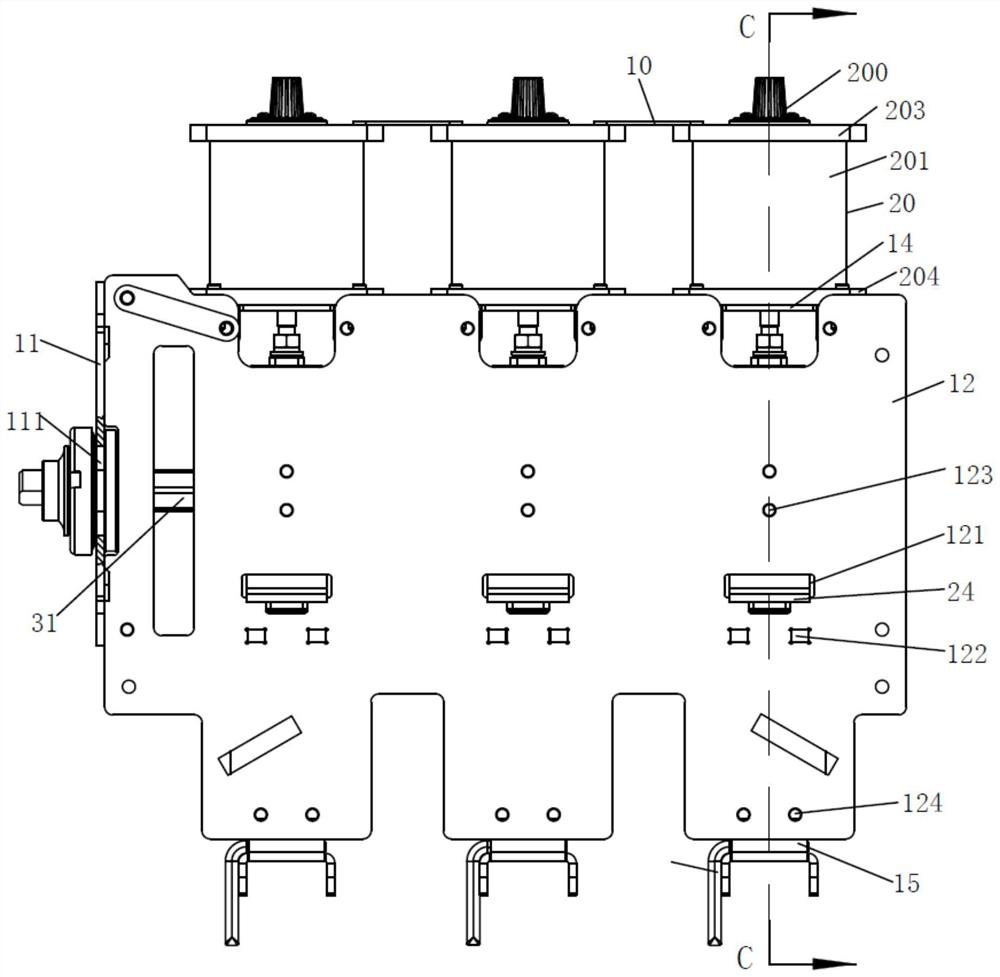

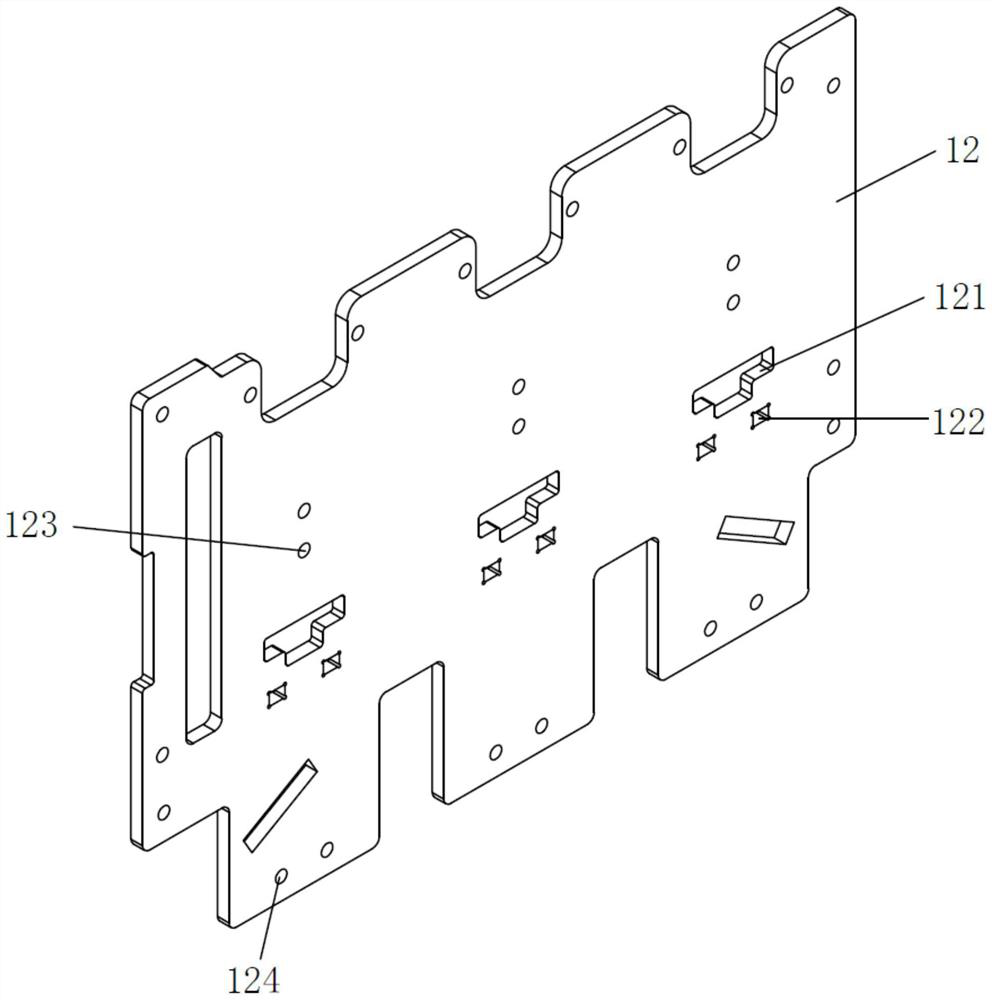

[0046]Such asFigure 1-18As shown, a permanent magnet vacuum circuit breaker, including a circuit unit and a receiving device for mounting the circuit unit, and the circuit unit comprises a permanent magnet mechanism 20, an insulating member 22, a connection assembly 23, a contact, a pressure spring 25, a conductive sheet 24, Vacuum arc interruption chamber 28, the switching and static contacts 29, and the same period, the permanent magnet mechanism 20 includes a dust cover 200 that the movable core tilt rod 206 and the anti-movable core tilt rod 206, the connection assembly 23 includes a first connecting rod 231, movable The core iron pulling rod 206 and the first connecting rod 231 are respectively provided with a milling, and the same assembly includes the same shaft 31, the transmission pin 33, the same seating seat 16, and the same period of the arm 32, respectively, respectively, respectively, respectively, respectively, the same axis 31 and the transmission pin 33 guide .

[0047...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com