A spring operating mechanism

A technology of operating mechanism and frame, applied in the direction of contact drive mechanism, protection switch operation/release mechanism, etc., can solve the problems of inconvenient buffer buffer performance, debugging, etc., and achieve compact structure, convenient installation and debugging, and small space occupation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

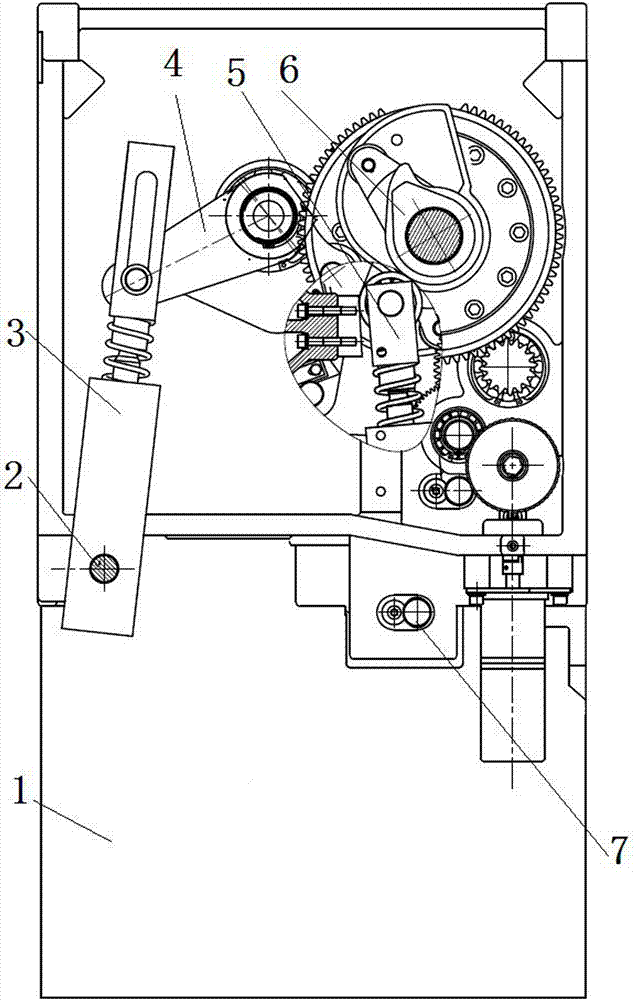

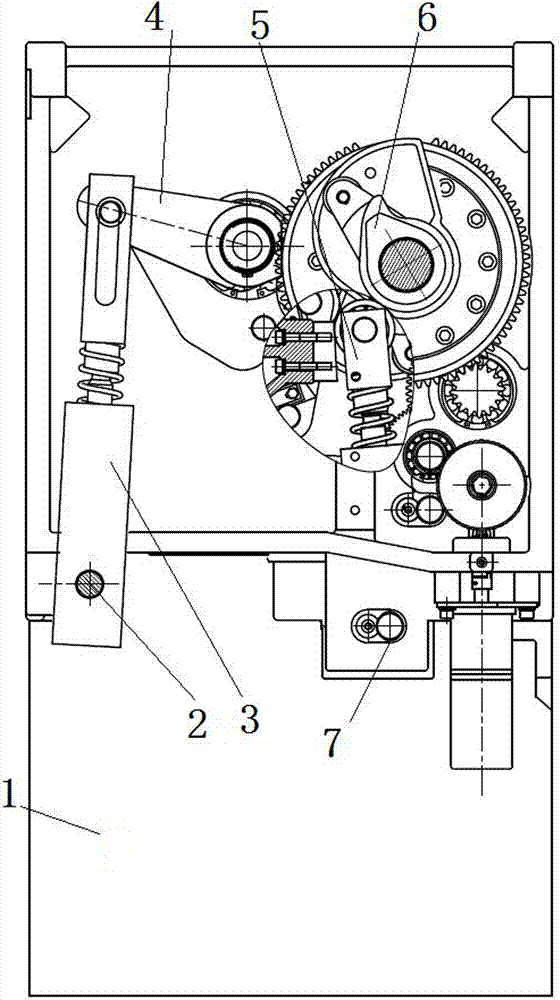

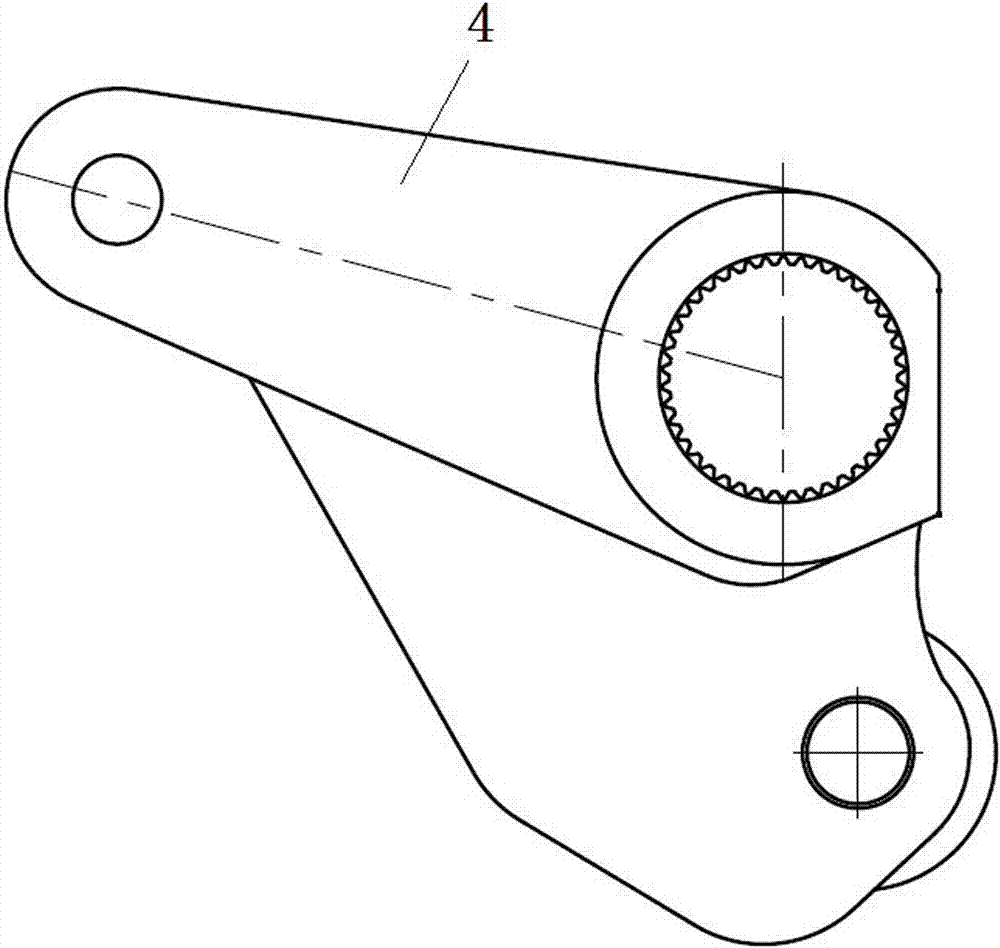

[0028] The embodiment of spring operating mechanism of the present invention: as Figure 1-14 As shown, the spring operating mechanism includes a frame 1, a transmission arm, and a closing cam 6, and the frame 1 is provided with an opening buffer 3 and a closing buffer 5 which are independently arranged. The opening buffer 3 includes the opening cylinder 32, the opening piston rod 37 coaxially guided and assembled with the opening cylinder 32, the left end (inner end) of the opening piston rod is provided with an opening piston part, the right end (outer end) ) is provided with a hinged part, and the hinged part is provided with a hinged long hole 42 for hinged connection with the transmission crank arm 4, and the length extension direction of the hinged long hole 42 is consistent with the length extension direction of the opening piston rod 37. The opening piston rod includes an opening piston rod body, the opening piston part is located at the left end of the opening piston ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com