Connector

A technology of connectors and terminal joints, applied in the field of connectors, to achieve the effects of enhanced locking force, improved operability, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

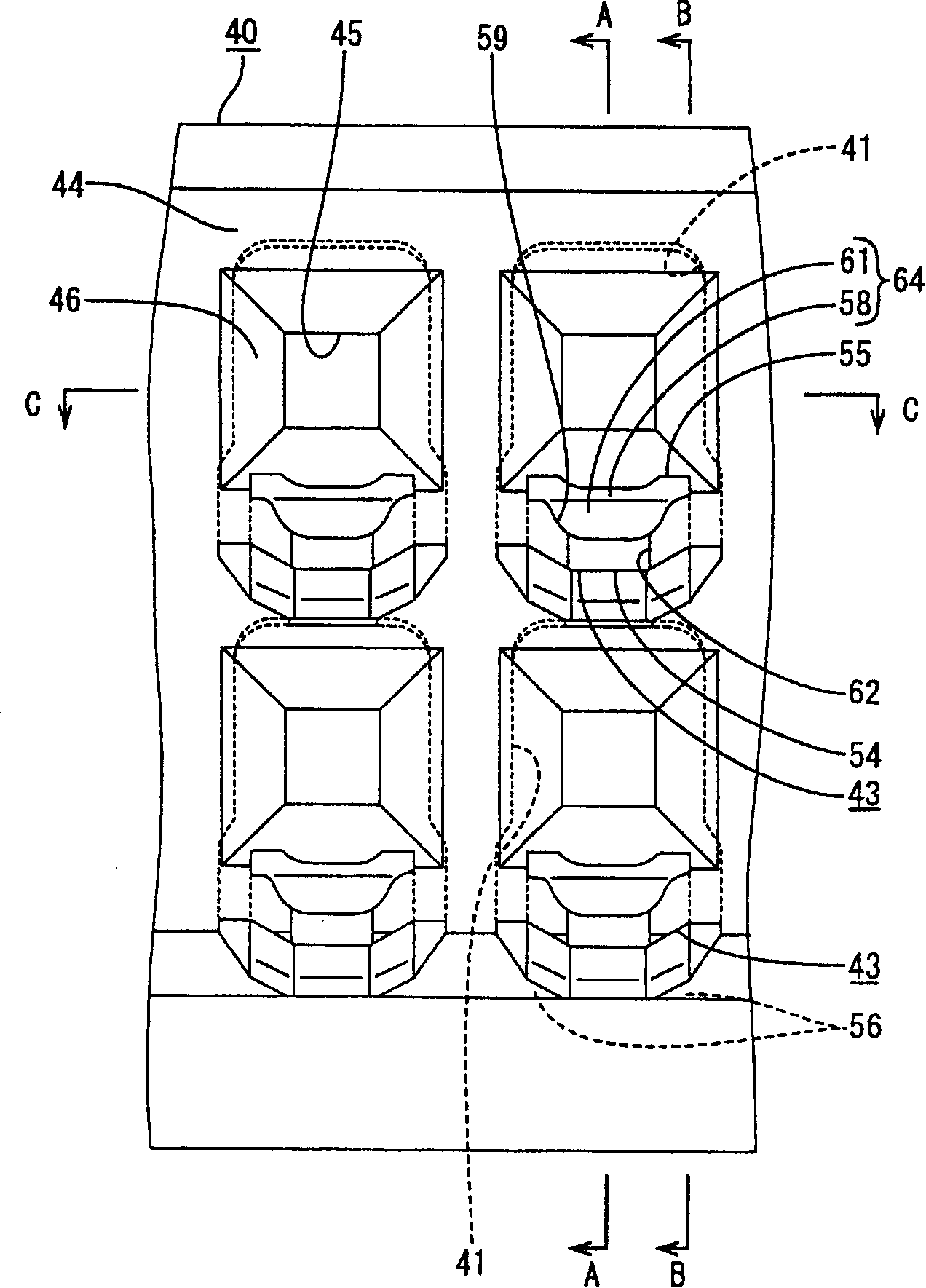

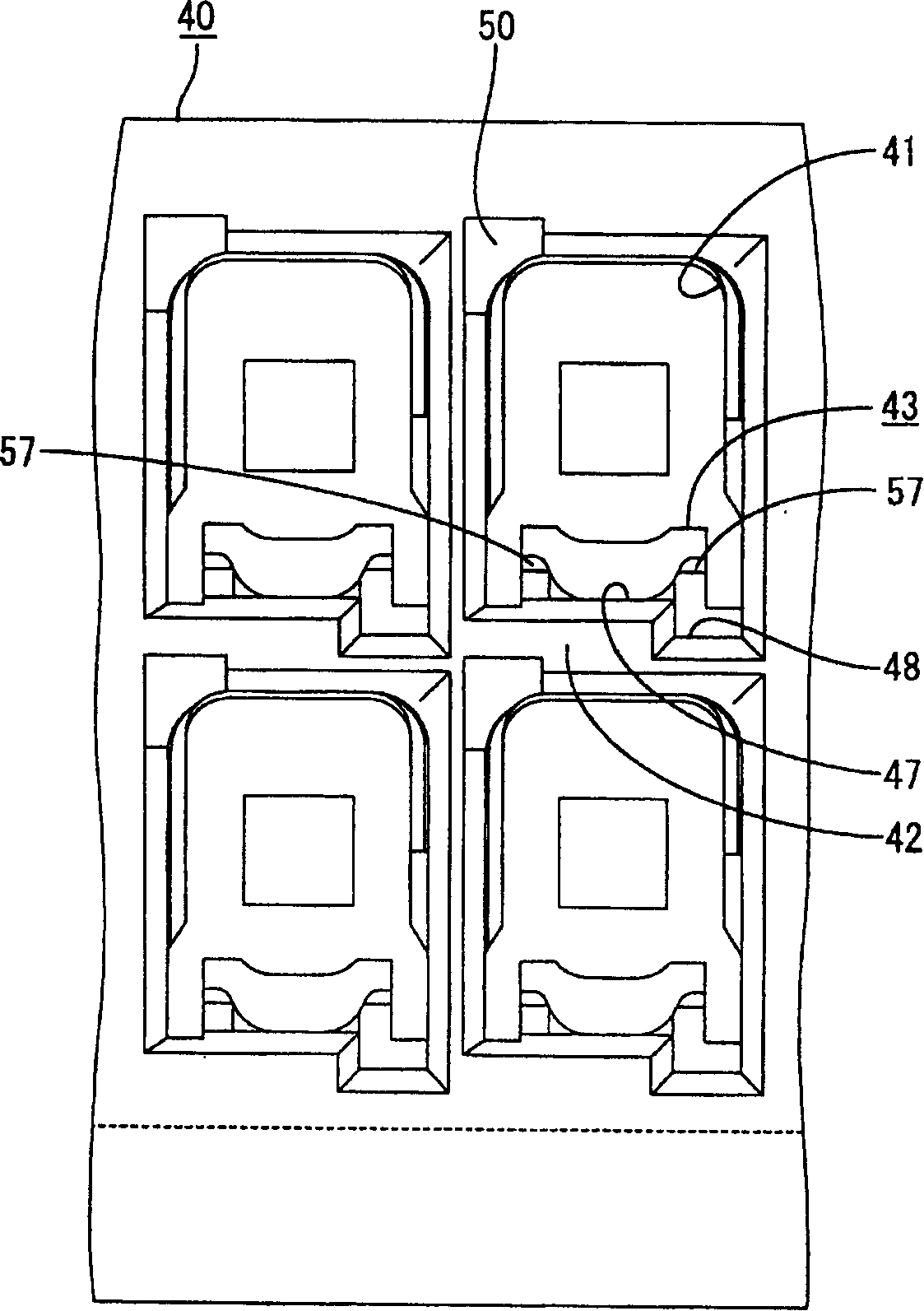

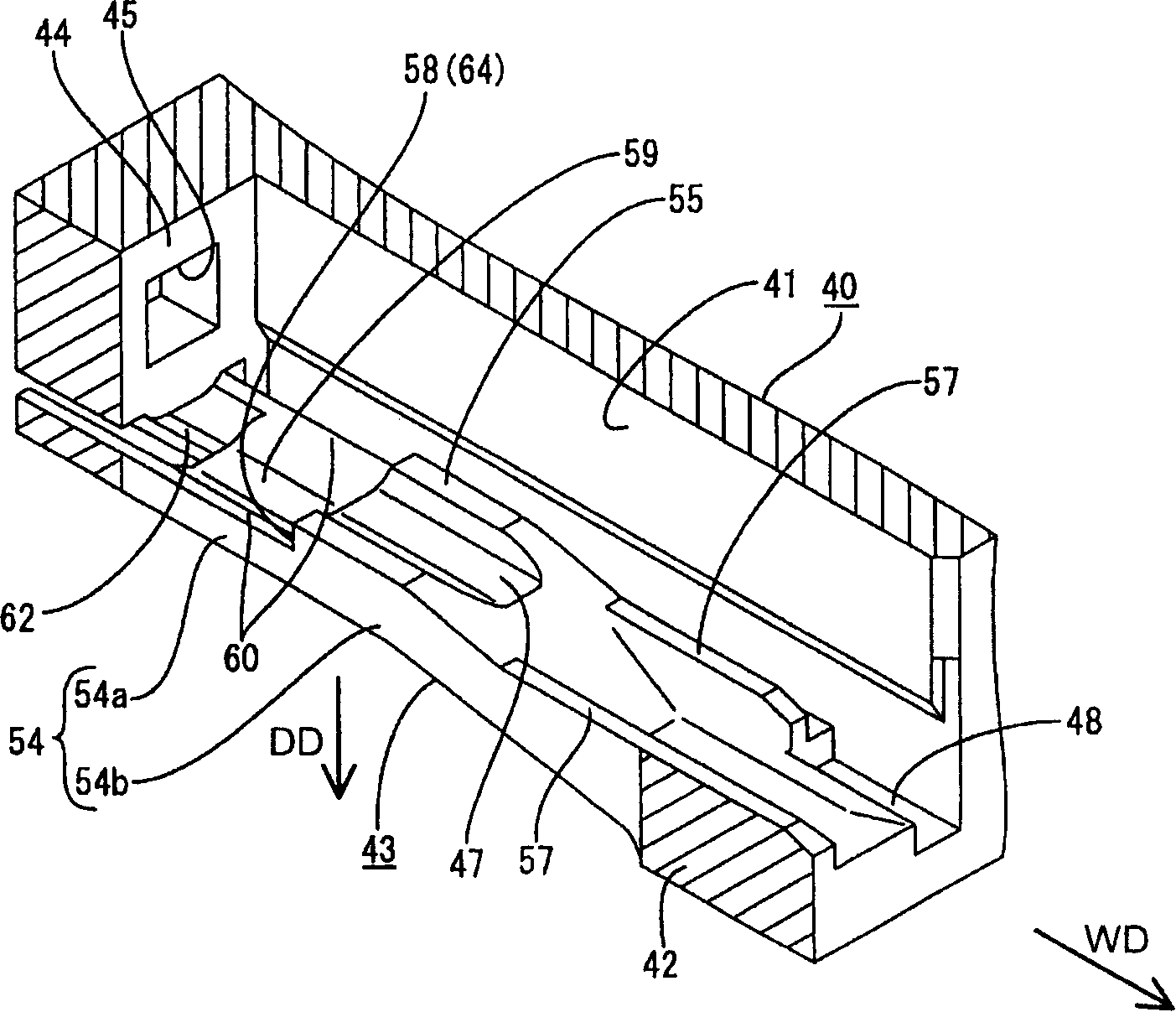

[0044] refer to Figures 1 to 1 6 describes a preferred embodiment of the present invention. In this embodiment, a female connector is shown in which one or more female terminal fittings 10 are at least partially inserted into a female connector housing 40 (hereinafter simply referred to as "female housing 40"). When at least partially housed in a female housing 40, the female terminal fitting 10 is electrically connectable to a male terminal fitting at least partially housed in a mating male housing (neither the male terminal fitting nor the male housing is shown), The male housing will be connected to the female housing 40 . In the following description, the directions 1WD in which the female terminal fitting 10 is inserted into the female housing 40 and withdrawn from the female housing 40 are referred to as the forward direction and the rearward direction, respectively, while reference is made to the vertical direction. Figure 7 .

[0045] The female terminal fitting 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com