Aluminum alloy formed by precipitation hardening and method for heat treatment thereof

A heat treatment method and precipitation hardening technology, which is applied in the field of precipitation hardening Al alloys and their heat treatment, can solve the problems of time-consuming heating, slow heating speed, reduced strength and ductility of Al alloys, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

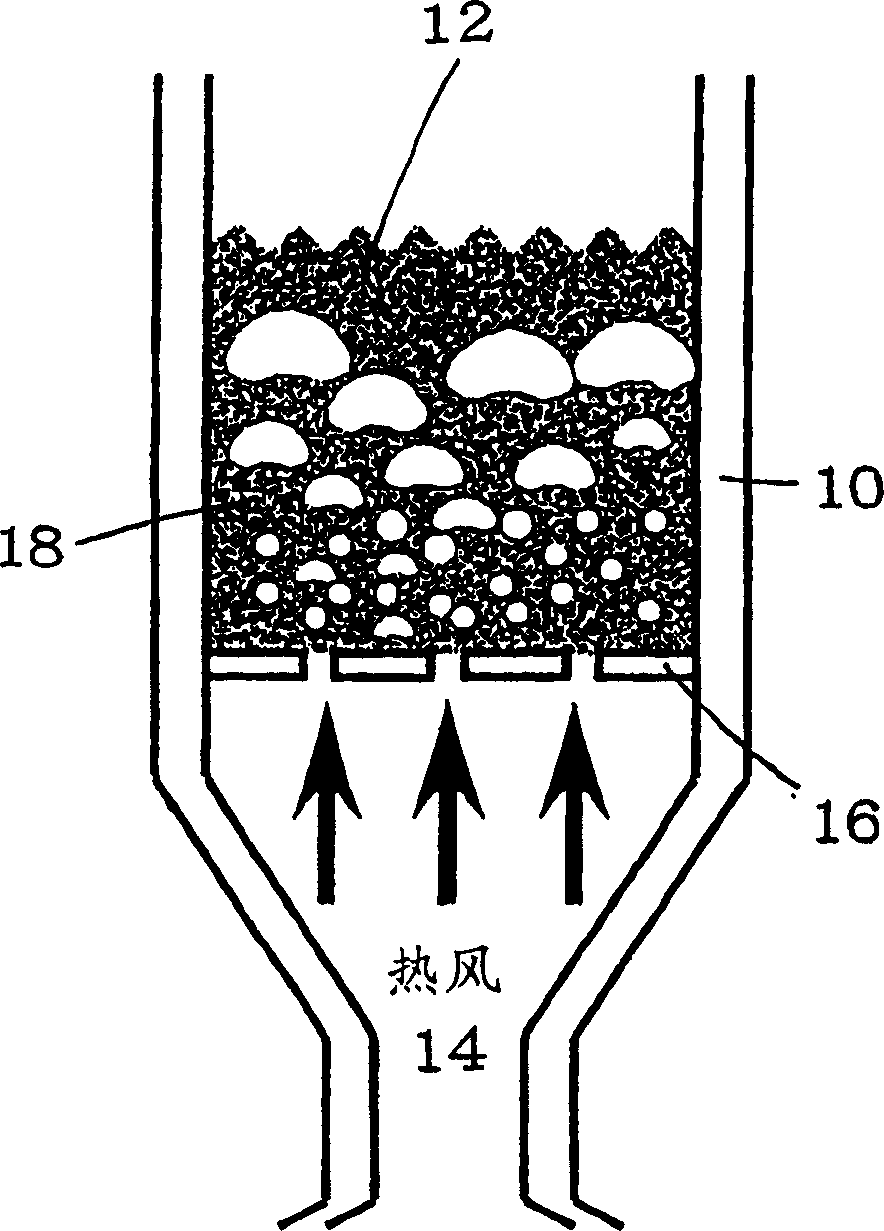

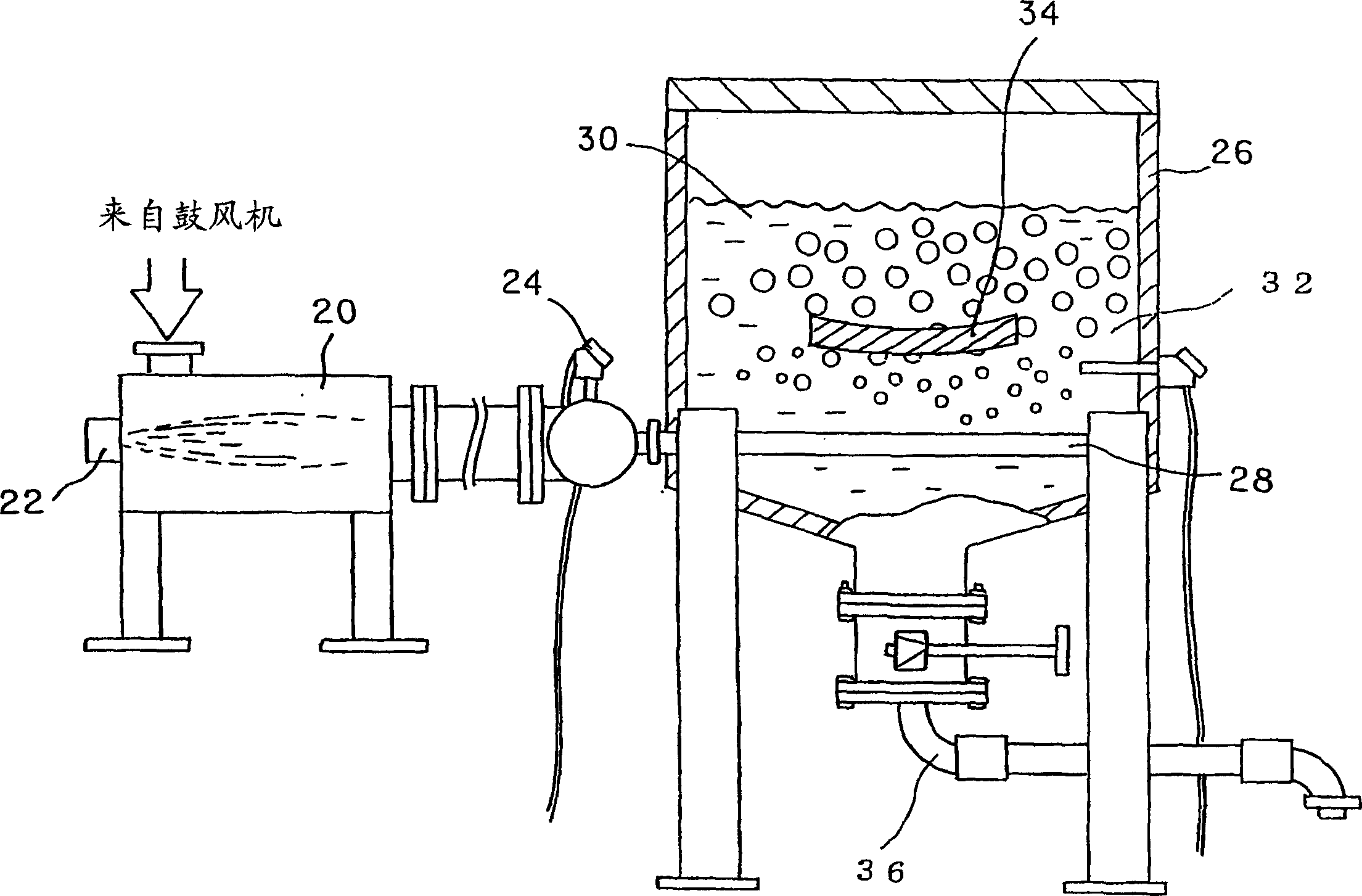

[0074] In a fluidized bed type solution annealing furnace, an atmospheric furnace was used as an aging furnace, and a method of heat-treating the cast of AC4CH Al alloy wheels was performed.

[0075] The fluidized bed solution annealing furnace has a square box shape of 1500mm×1500mm on one side, the height of the straight cylindrical part is 1800mm, and the lower part is composed of a trapezoidal fluidized bed container. In addition, the aging treatment furnace used a tunnel furnace (normal pressure furnace) well-known in the prior art. As the particulate matter, quartz sand having an average particle diameter of 50 to 500 μm is used.

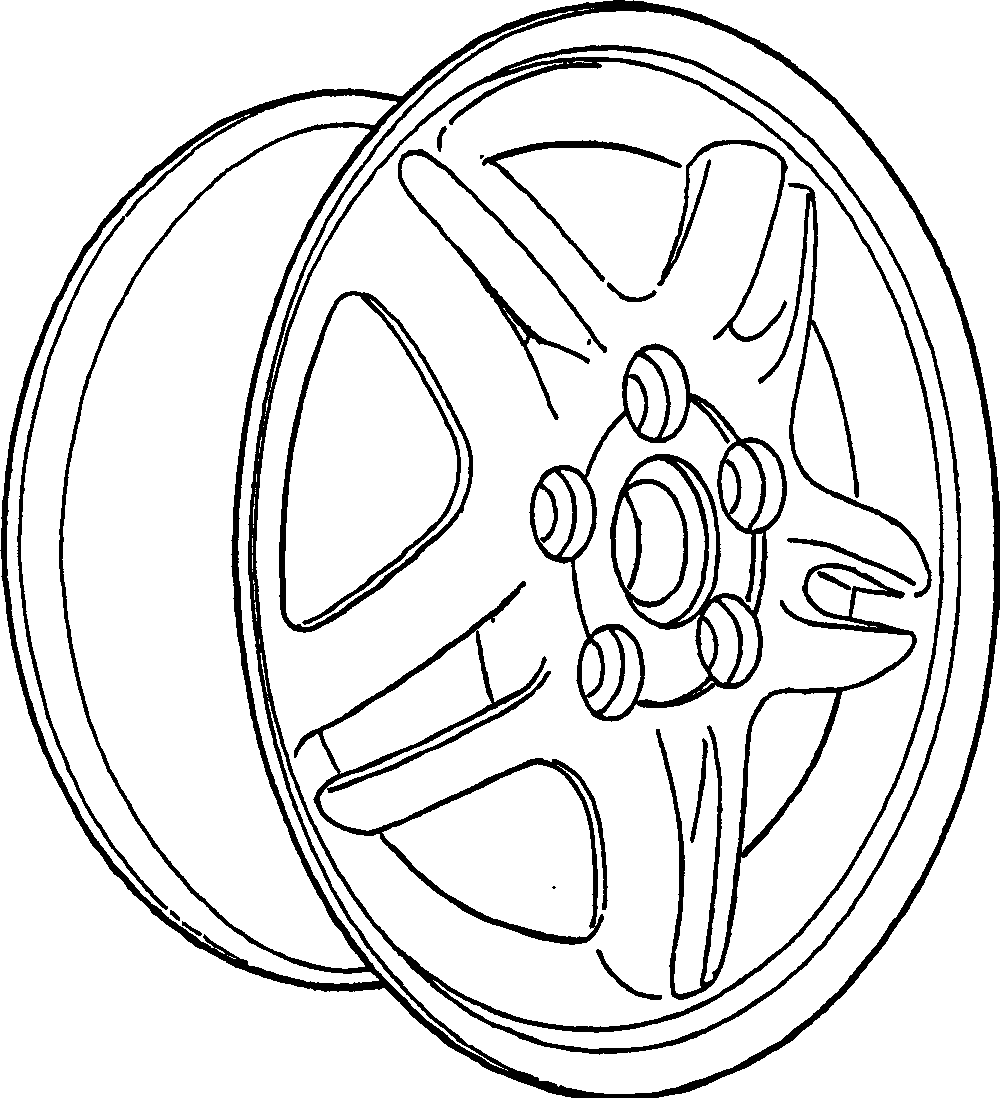

[0076] As the object of heat treatment, use image 3 In the shown cast aluminum wheel (14kg) for a vehicle, the test pieces are collected at three locations: the outer rim flange, the inner rim flange, and the spokes. The composition of the above-mentioned AC4CH Al alloy aluminum wheel contains 7.0% by mass of Si, 0.33% by mass of Mg, and 40ppm of...

Embodiment 2

[0084] As in Example 1, a test piece ( Figure 8 ), perform a rotating bending fatigue test to obtain the fatigue strength.

[0085] Here, the rotating bending fatigue test uses an Ono-type rotating bending fatigue tester. The test piece 1 is rotated at 3600 rpm in the atmosphere at room temperature and the stress is applied at a stress ratio of -1 at the same time. The relationship between the stress at the time of failure and the number of repetitions Measure fatigue strength. The result is shown in Figure 9-10 .

Embodiment 3

[0087] In Example 1, a test piece was collected from a vehicle aluminum wheel obtained when the solution annealing temperature was 550°C for 60 minutes, and the average area of the eutectic structure was measured as in Example 1.

[0088] The results are shown in Table 1. In addition, the results of the tensile test (tensile strength, 0.2% yield strength, elongation) at this time are shown in Picture 11 .

[0089] Sample name

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com