Inner weight correcting method for electronic high-accuracy balance

An electronic balance, high-precision technology, applied in the field of weighing instruments, can solve problems such as difficulty in weight adjustment, calibration deviation, and difficulty in correcting internal calibration weights.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

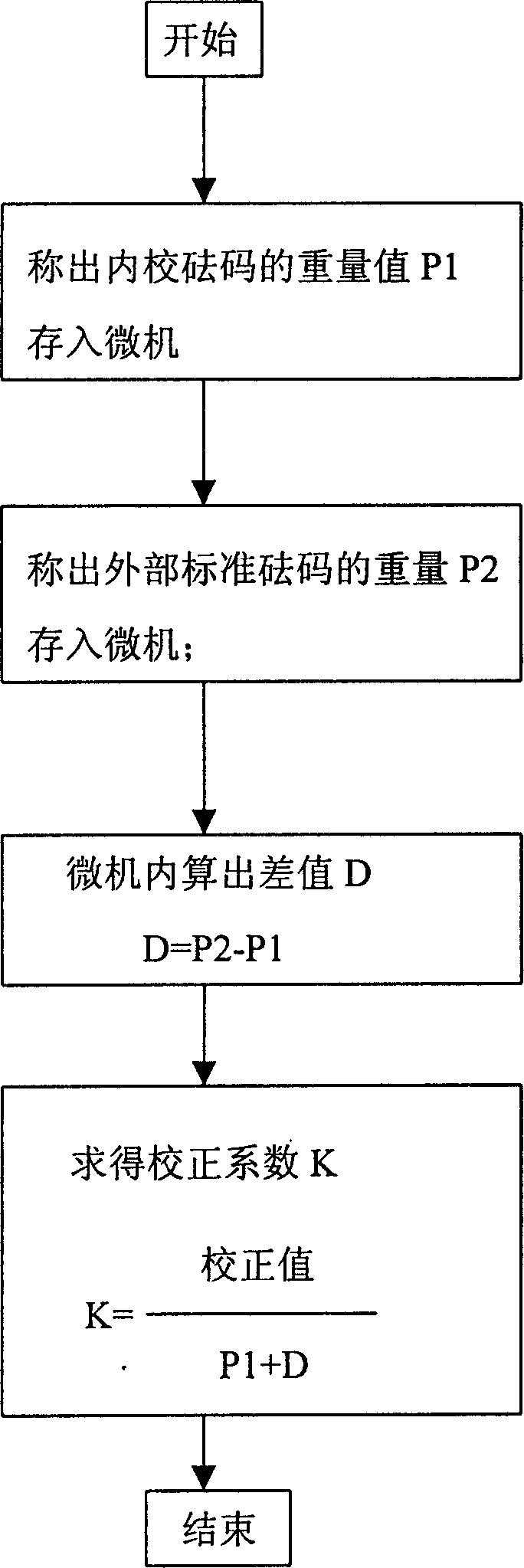

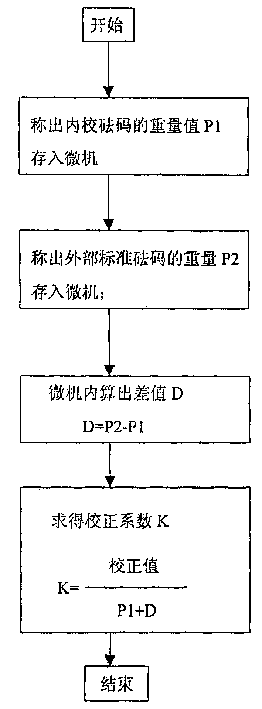

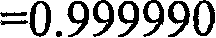

[0012] This implementation makes an explanation according to the flow chart. For example, there is an electronic balance with a weighing range of 200 grams and an actual division value of 0.0001 grams. The nominal value of the internal calibration weight is 200 grams. First start the program, and use the weighing system of this balance to weigh the weight value P1 of the internal calibration weight as 200.0010 grams, and store it in the memory of the computer, and then use a standard weight of 200 grams with an error of less than 0.05 mg, which is also in the balance. The weighing system weighs its weight P2 as 200.0020 grams, and the difference D obtained in the microcomputer is D=P2-P1, which is 200.0020-200.0010=.0010 grams, which is the correction amount of the internal calibration weight, according to the formula: = 0.999990 Multiply the K value with the weighing data to get an accurate digital display.

[0013] Its weighing process is: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com