Optimum lifter for slide cushion plate-transport device

A lifting device and lifter technology, which is applied in the direction of lifting devices, lifting frames, conveyor objects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

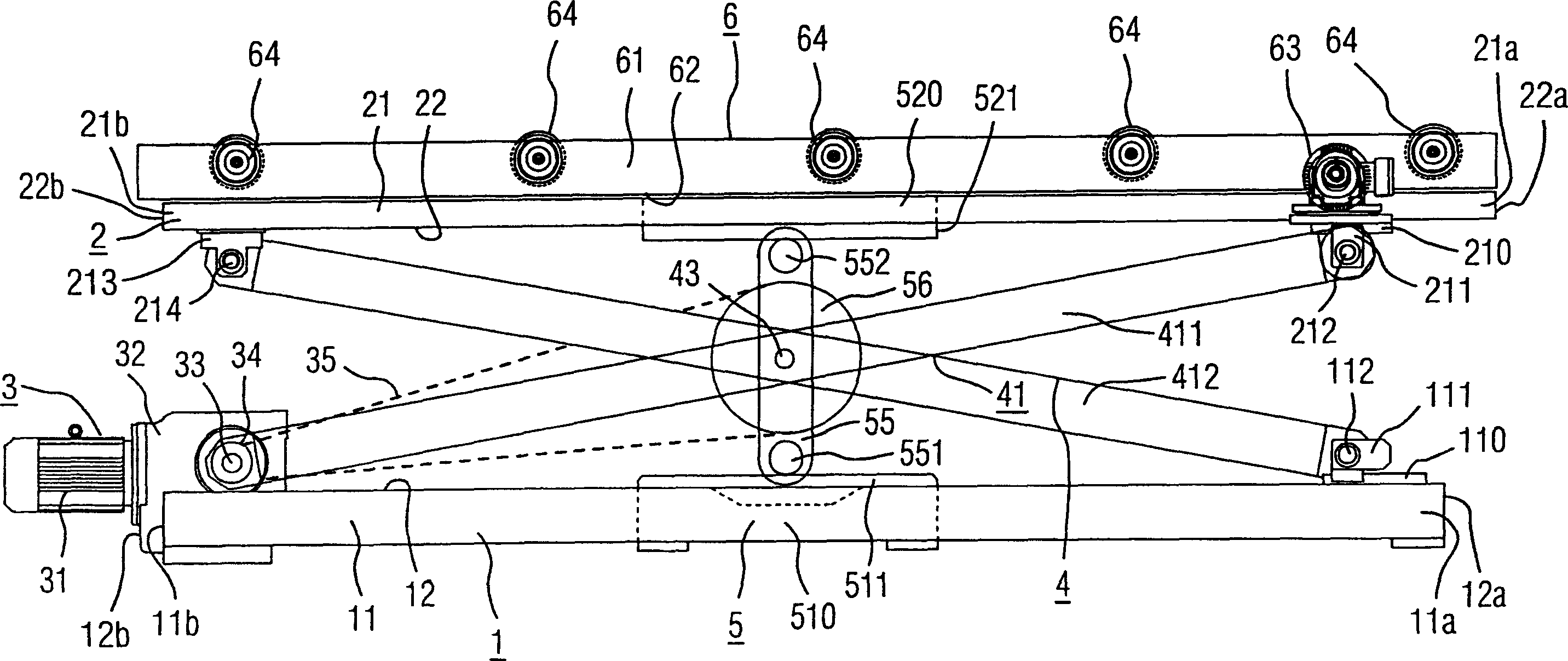

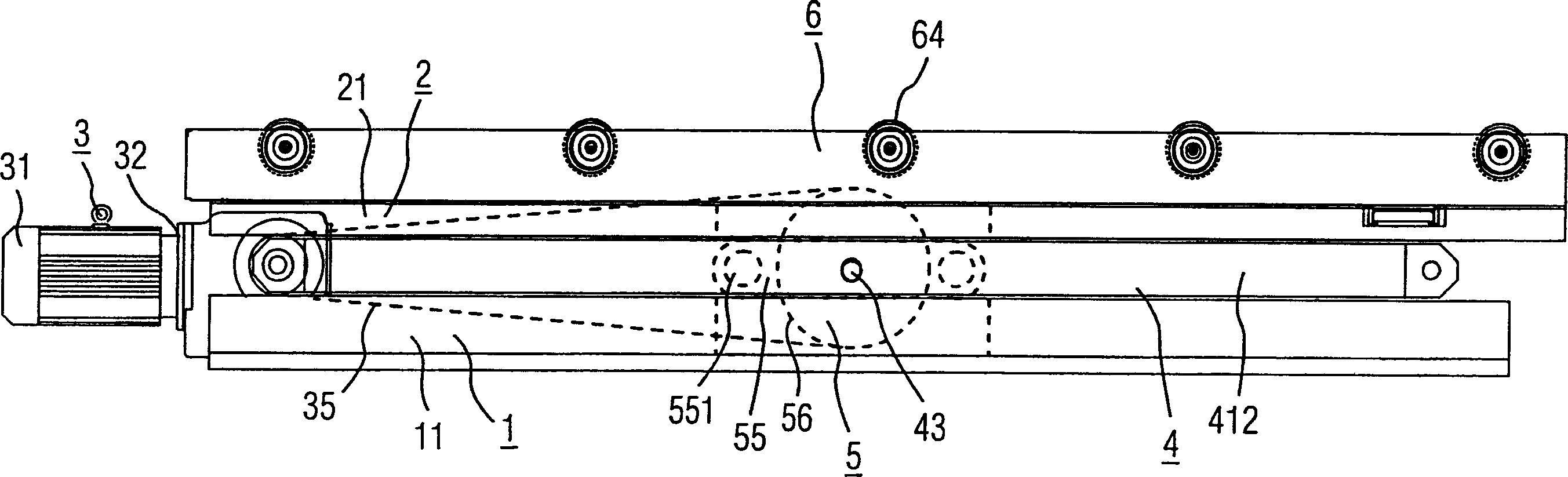

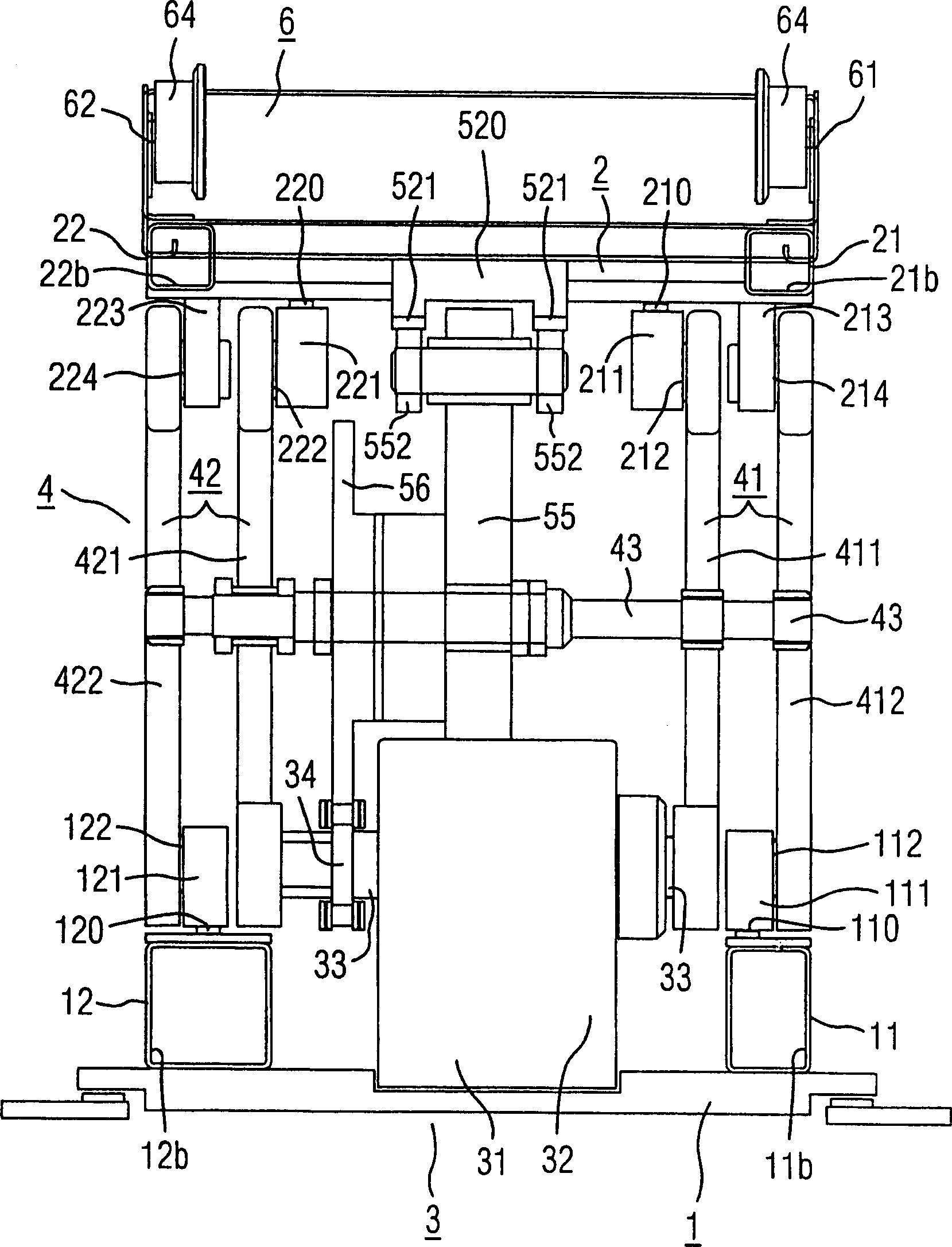

[0018] figure 1 A particularly advantageous embodiment of the lifting device according to the invention is shown as an example in a side view, in which the lifting device has been raised to the top dead center, ie to the structurally permitted maximum lifting height.

[0019] figure 1 The bottom frame of the shown design has a first and a second stringer 11 , 12 , wherein the stringer 11 lies in the plane of the drawing and the stringer 12 is behind the plane of the drawing. These longitudinal beams are firmly connected to each other by corresponding cross braces.

[0020] Between the rear end side 11b of the first longitudinal beam 11 and the rear end side 12b of the second longitudinal beam 12, a driving part 3 is mounted on the bottom frame. It preferably comprises a drive motor 31 followed by variable speed transmission 32 . On the central drive shaft 33 of the transmission 32 , which extends transversely to the longitudinal beams 11 , 12 , is mounted on the one hand a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com