Linear motor capable of positioning load

A technology of linear motors and coil groups, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of large attraction of magnets and coil laminations, large total mass of magnets and back irons, and limited coil acceleration, etc., to achieve static friction Effects of reduced force, shorter response time, and reduced moving mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

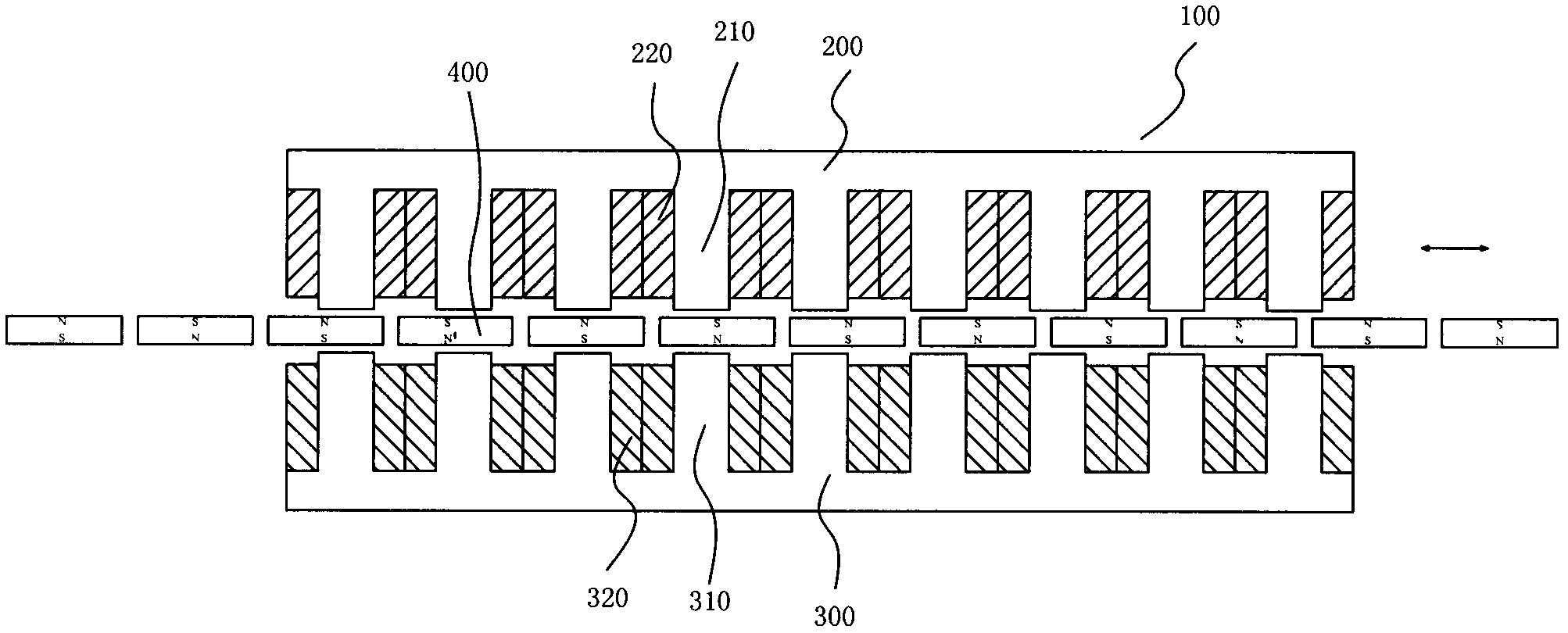

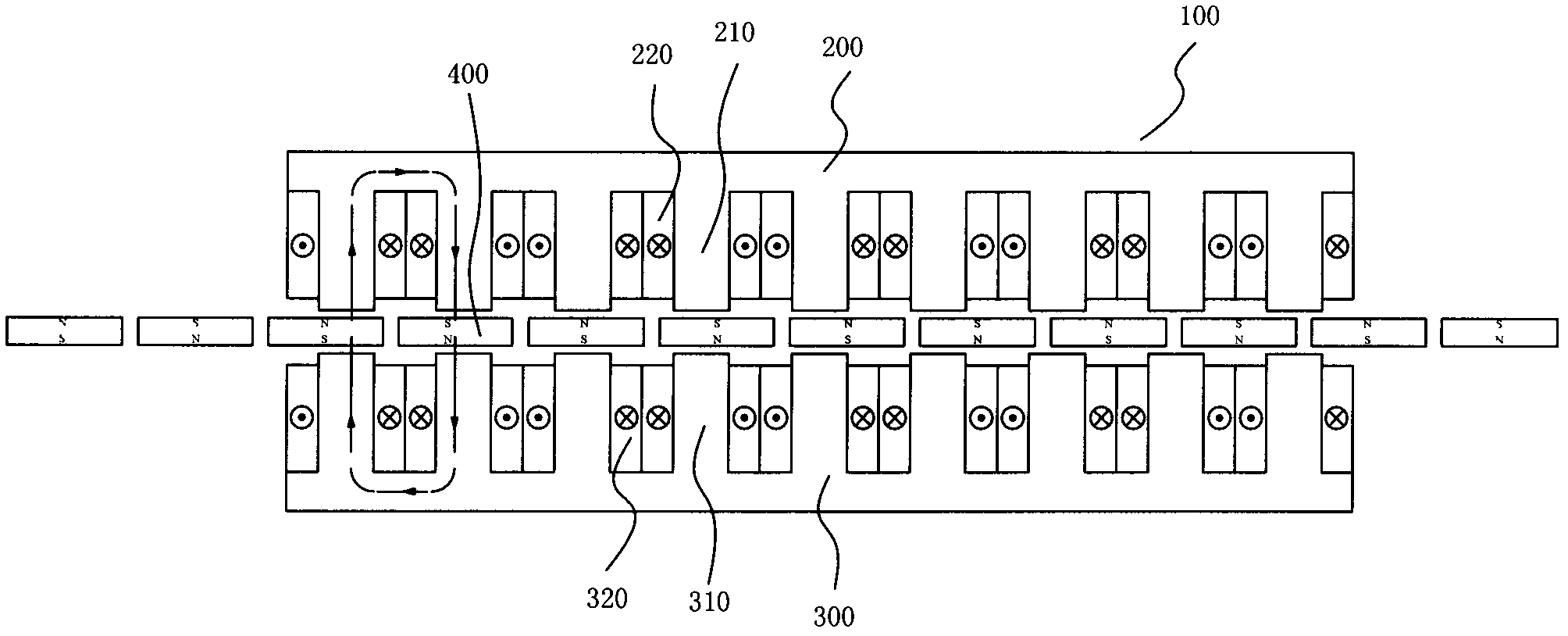

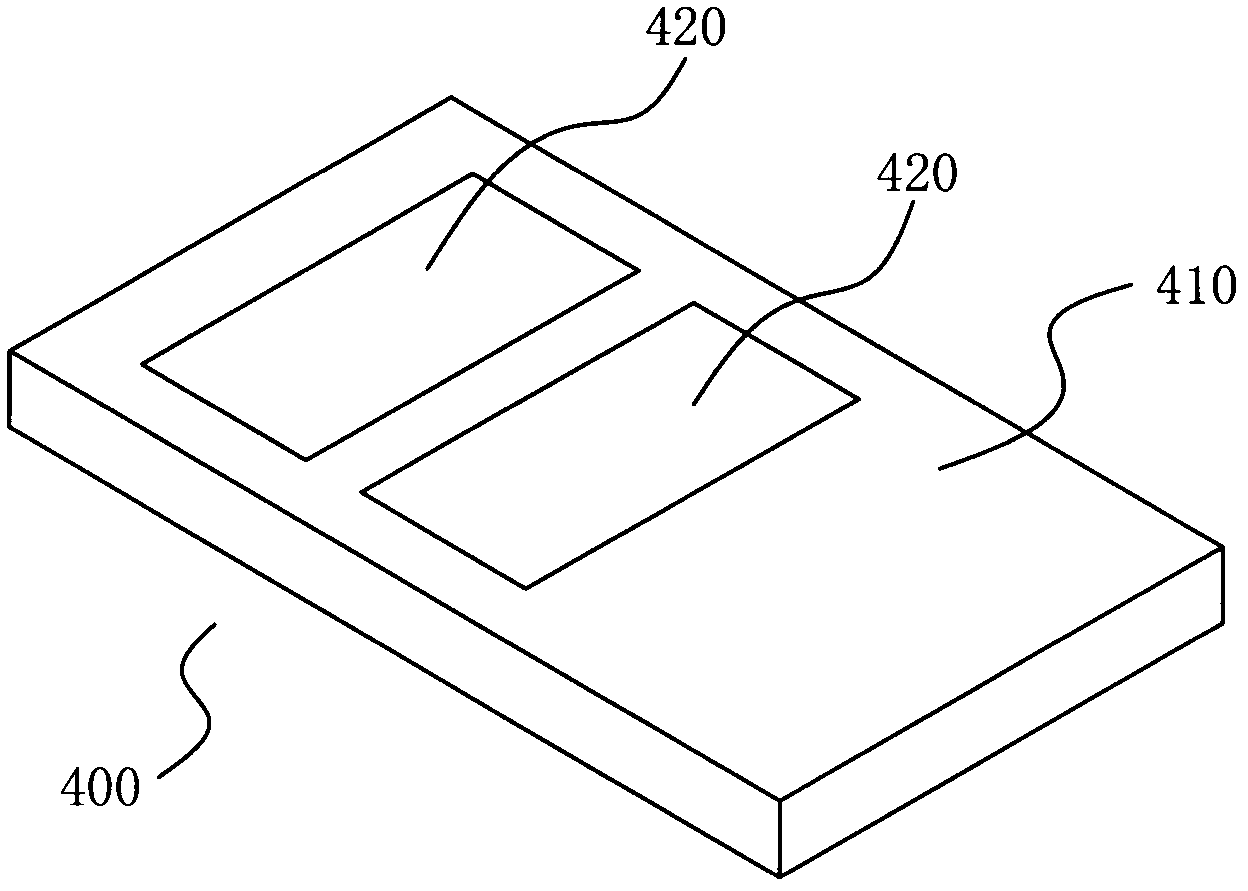

[0086] see figure 1 , a linear motor for positioning loads, including a coil set 100 and a magnet row 400, the coil set 100 and the magnet row 400 are arranged in a straight line. The coil group 100 is two groups, including an upper coil group 200 and a lower coil group 300. The upper coil group 200 includes an upper stator tooth 210 and a coil 220 wound on the upper stator tooth 210, and the lower coil group 300 includes a lower stator tooth 310 and a coil wound on the upper stator tooth 210. The coil 320 on the lower stator tooth 310 , the upper stator tooth 210 and the lower stator tooth 310 are disposed opposite to each other, and the magnet row 400 is disposed in the middle of the two coil groups 100 . The distance between the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com