Process for preparing aluminium oxide nano fibre

A technology of alumina nano and fiber, applied in chemical instruments and methods, alumina/aluminum hydroxide, colloid chemistry, etc., can solve the problems of expensive and complicated raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

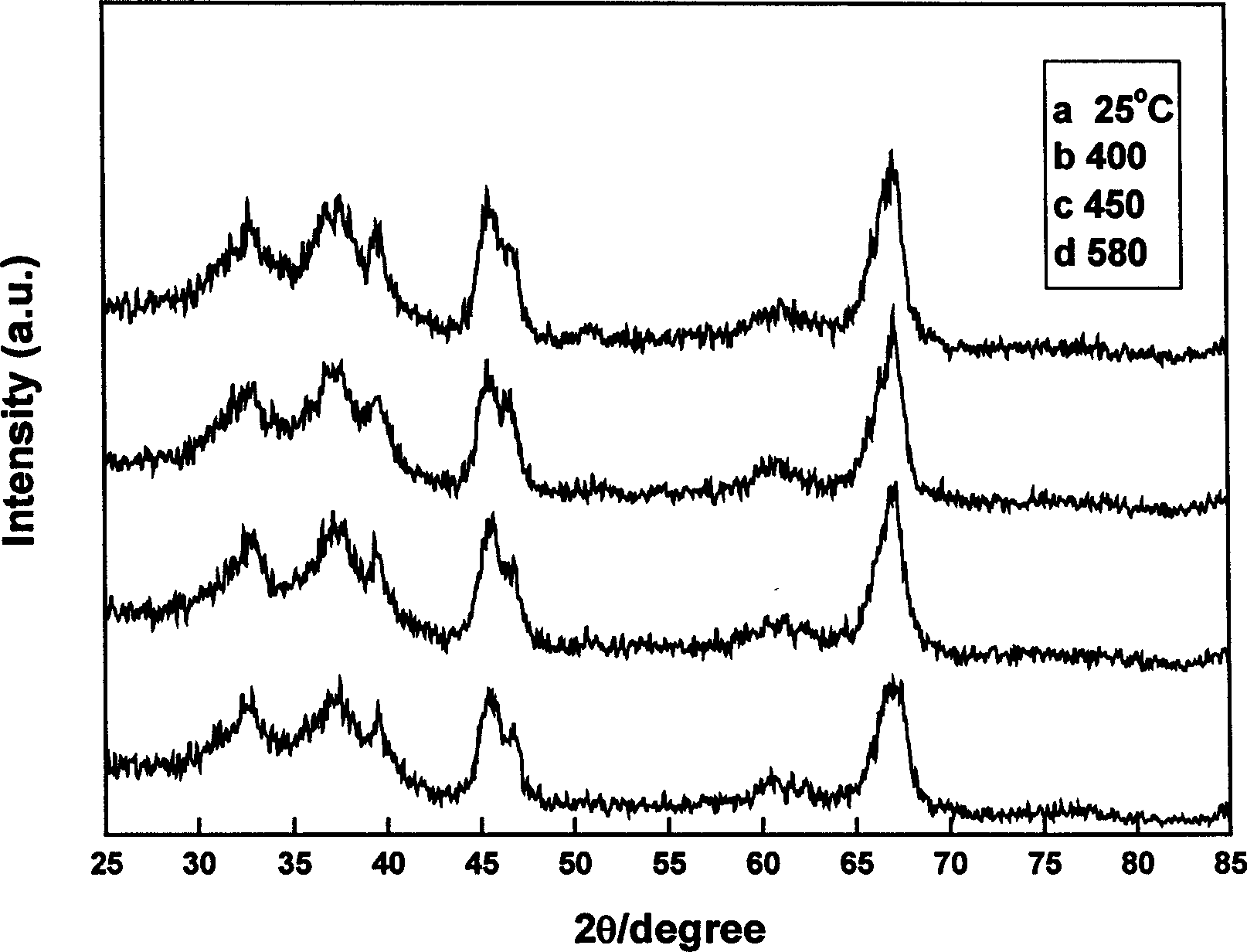

[0020] Dissolve 14g of hexamethylenetetramine in 30ml of water to prepare solution A, dissolve 15g of aluminum nitrate in 20ml of water to prepare solution B, slowly drop solution A into solution B under stirring (control temperature at 30°C) to obtain clear transparent sol. The sol was hydrolyzed in a 70°C water bath for 60 minutes to obtain a transparent gel. The resulting gel was soaked in absolute ethanol for one day and then replaced with fresh ethanol. This was repeated three times in a row to extract the water therein, and the obtained gel was used for supercritical drying. See the above content for the supercritical fluid operation process. The alumina nanofiber precursor is calcined in a muffle furnace to prepare alumina nanofibers, and the calcining temperatures are 400°C, 450°C, 500°C, and 580°C. The sample BET test results are shown in Table 1, and the sample XRD analysis results are shown in Table 1. figure 1 , the TEM results of the samples are shown in Figu...

Embodiment 2

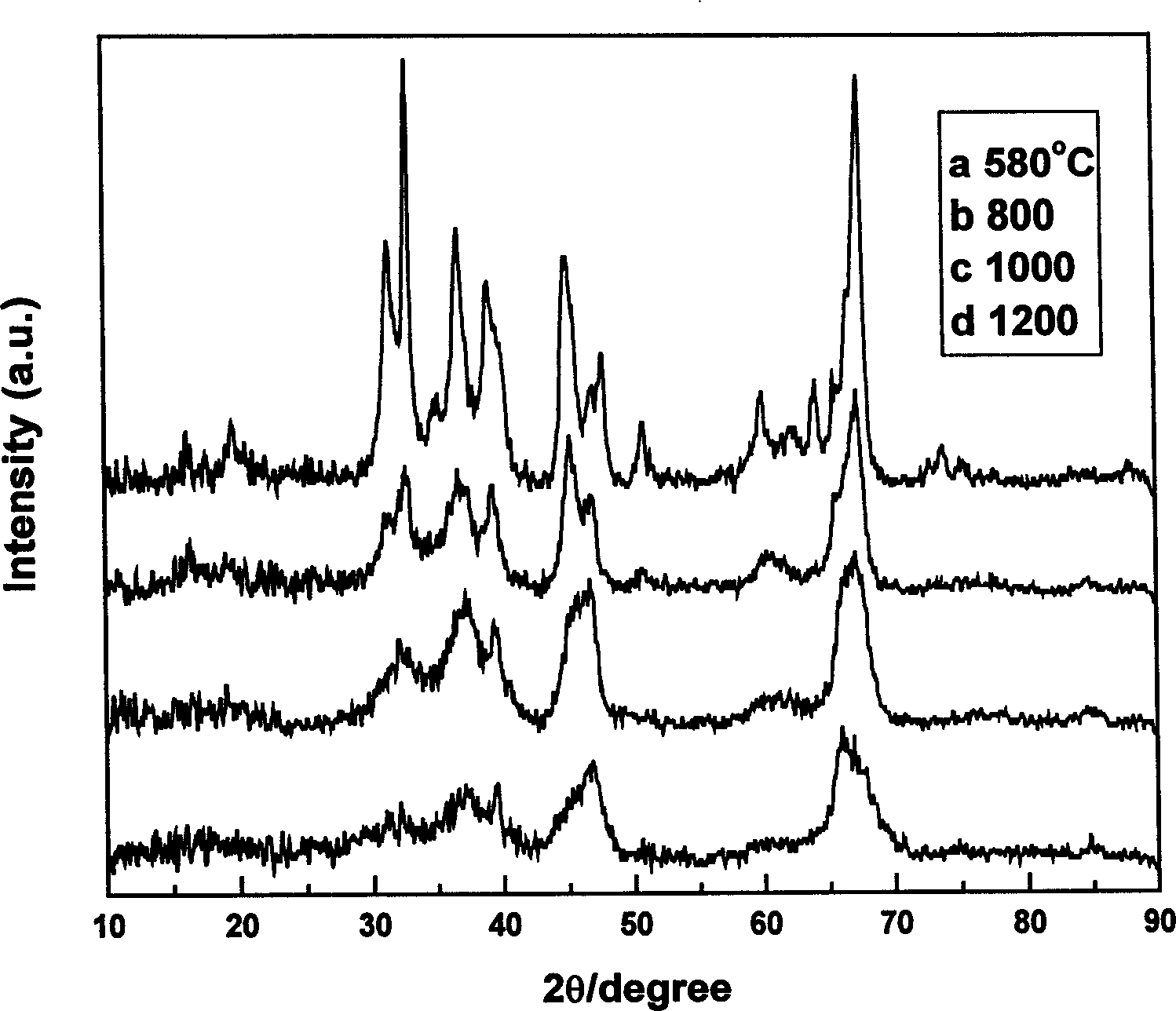

[0021] Dissolve 7g of hexamethylenetetramine in a mixed solution of 31ml of ethanol and 7ml of water to obtain solution A, dissolve 15g of aluminum nitrate in a mixed solution of 16ml of ethanol and 4ml of water to obtain solution B, slowly drop solution A under stirring Add solution B (control the temperature at 30° C.) to obtain a clear and transparent sol. The sol was placed in a 70ml hydrothermal kettle at 95°C for 2 hours to obtain a milky white gel. After aging for 1 day, the gel became transparent, and the obtained gel was used for supercritical drying. See the summary of the invention for the supercritical fluid operation process. The alumina nanofiber precursor is calcined in a muffle furnace to prepare alumina nanofibers, and the calcining temperatures are 580°C, 800°C, 1000°C, and 1200°C. The sample BET test results are shown in Table 1, and the sample XRD analysis results are shown in Table 1. figure 2 , the sample TEM results are shown in Figure 6 , Figure ...

Embodiment 3

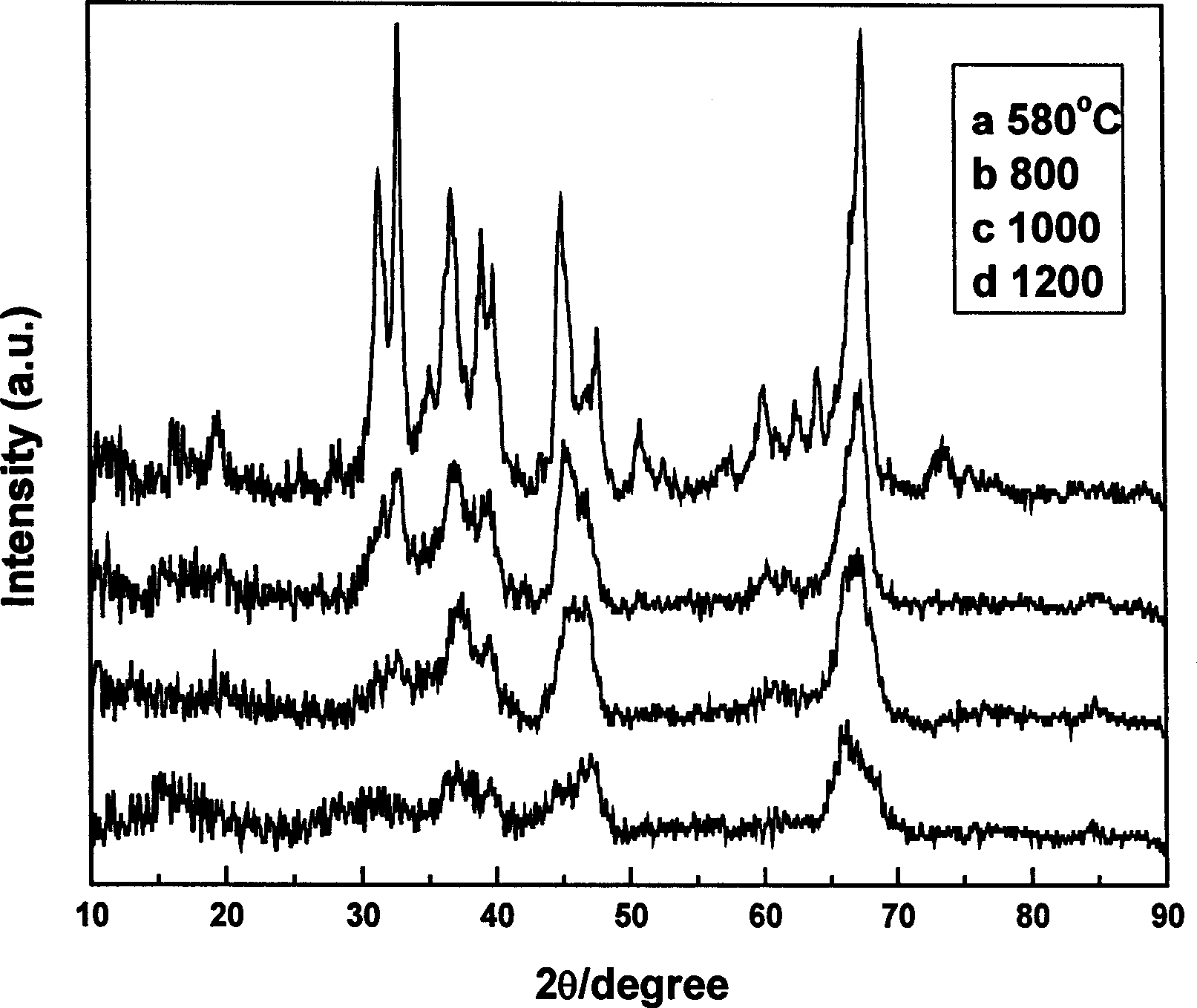

[0022] Dissolve 4.2g of hexamethylenetetramine in a mixed solution of 31ml of ethanol and 5ml of water to prepare solution A, dissolve 15g of aluminum nitrate in a mixed solution of 16ml of ethanol and 4ml of water to prepare solution B, and dissolve the solution under stirring A was slowly dropped into solution B (controlling the temperature at 30°C) to obtain a clear and transparent sol. The sol was placed in a 70ml hydrothermal kettle at 95°C for 2 hours to obtain a milky white gel. After aging for 1 day, the gel became transparent, and the obtained gel was used for supercritical drying. See the summary of the invention for the supercritical fluid operation process. The alumina nanofiber precursor is calcined in a muffle furnace to prepare alumina nanofibers, and the calcining temperatures are 580°C, 800°C, 1000°C, and 1200°C. The sample BET test results are shown in Table 1, and the sample XRD analysis results are shown in Table 1. image 3 , the sample TEM results are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com