Machine for cutting wafers

A technology for cutting machines and wafers, applied in the direction of routers, sawing equipment, metal sawing equipment, etc., can solve the problems of small parallel cutting, separation disc approach, low function and efficiency of wafer cutting machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

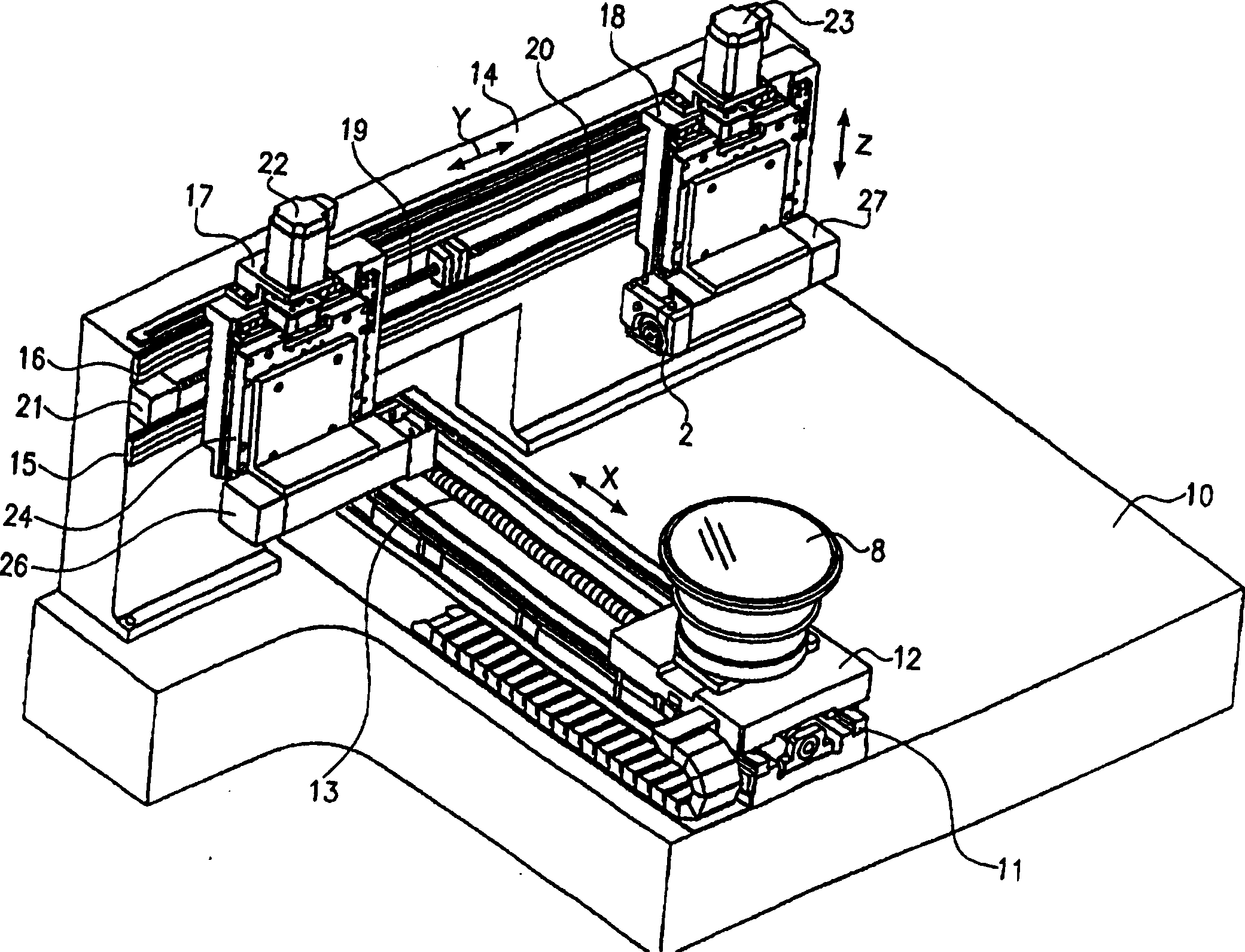

[0020] figure 1 is a perspective view of a wafer dicing machine according to the present invention. The cutting machine comprises a frame 10 fastened to a guide 11 supporting thereon a carriage 12 in a longitudinally displaceable manner on the guide 11 . The carriage 12 can be moved, for example, by means of a ball screw 13 . The carriage 12 carries a working platform 8 which is rotated around a vertical axis by a drive (not shown).

[0021] The frame 10 secures an operating table 14 comprising mutually parallel horizontal guides 15, 16 on which carriages 17, 18 are supported in a horizontally movable direction. Their movement is achieved by means of ball screws 19, 20 or similar, here moved by a drive 21 in a known manner.

[0022] The two carriages 17 and 18 each have mounted thereon a motor 22 and 23 for vertically moving the carrying carriages 24, 25 by means of a drive system (not shown).

[0023] The carrier slides 24 , 25 each have a bearing block 26 , 27 each havin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap