Stable type building timber equal-distance cutting device

An isometric cutting and cutting device technology, applied in wood processing appliances, forming/shaping machines, special forming/shaping machines, etc. The effect of precise cutting distance, improved stability, and improved practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

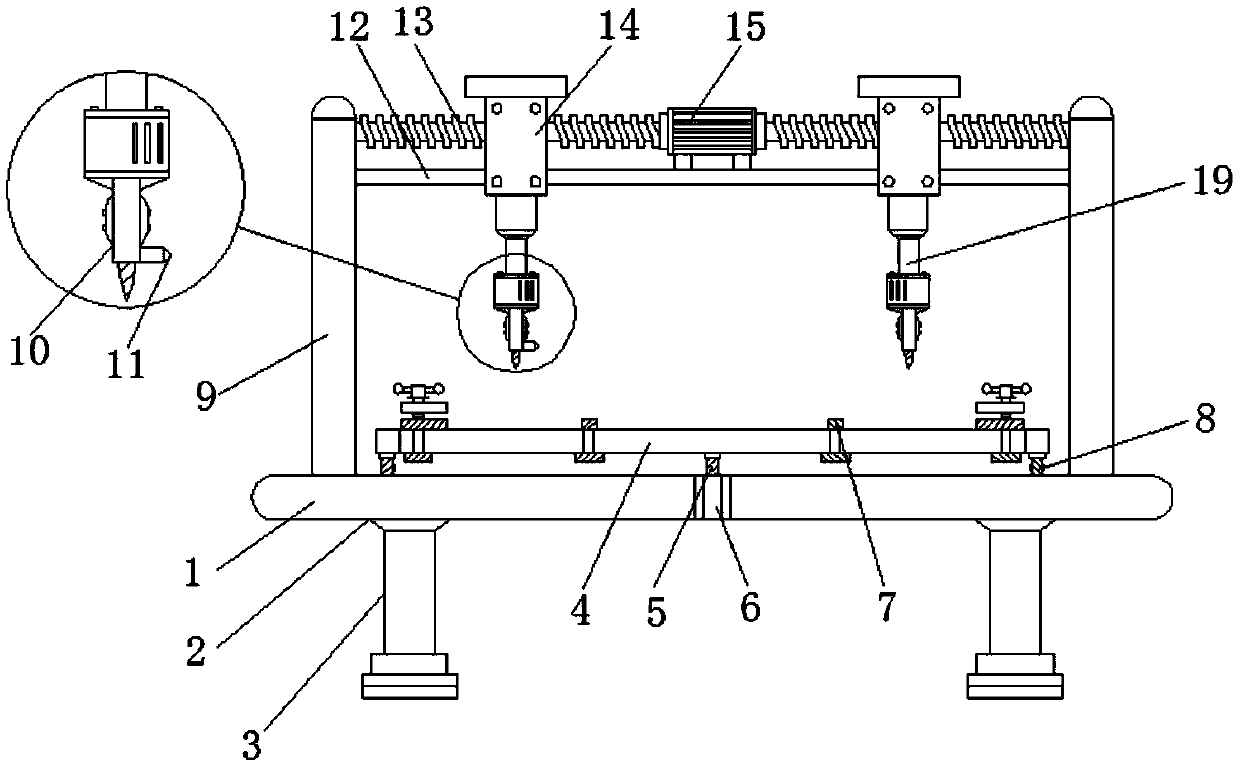

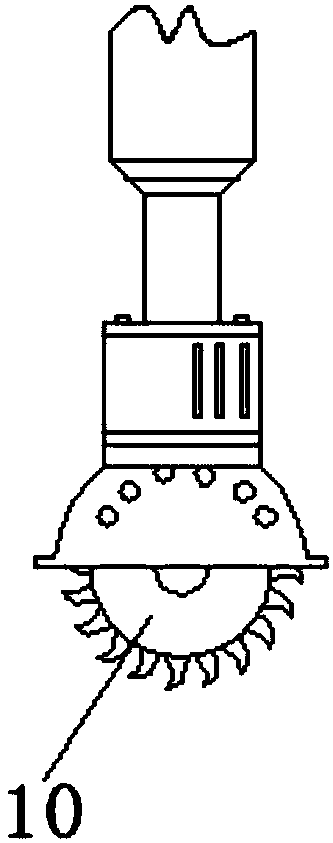

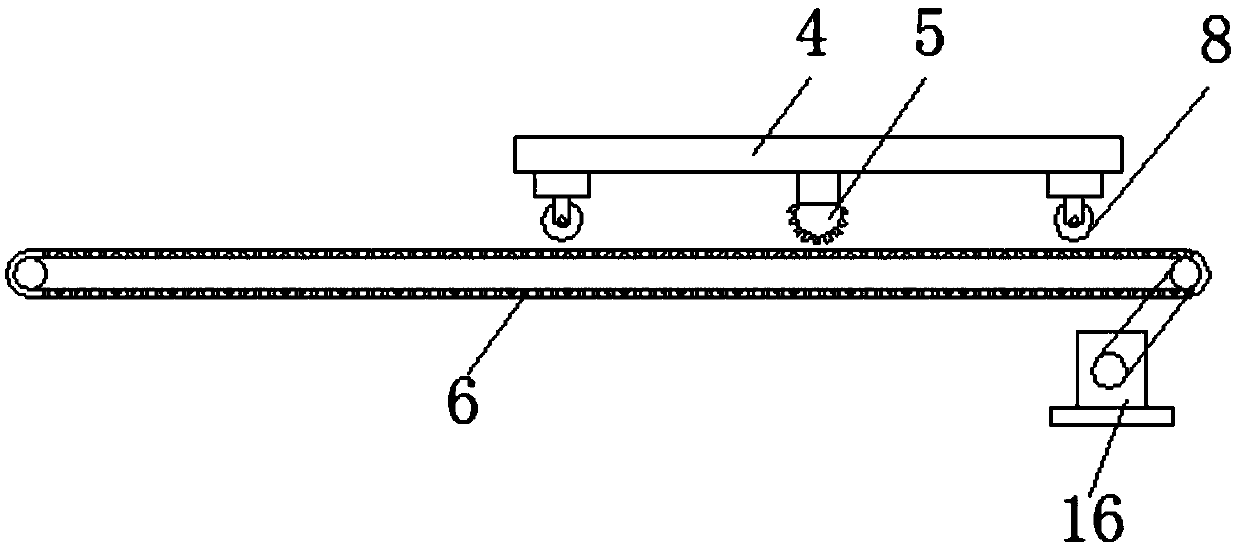

[0021] refer to Figure 1-4 , a stable construction timber equidistant cutting device, comprising a cutting device body 2, a fixed plate 4, a cutting machine 10 and a biaxial motor 15, characterized in that the bottom of the cutting device body 2 is symmetrically provided with support legs 3, and supports The top of the leg 3 is fixedly connected with the worktable 1, and the top of the worktable 1 is slidably connected with the fixed plate 4 through the pulley 8, and the fixed plate 4 passes through the chute 17, the limit bar 18 and the support bar symmetrically opened on the front and rear sides. 7 Sliding connection, the middle position of the bottom of the fixed...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap