Tricot machine

A warp knitting machine and yarn feeding technology, which is applied in the field of warp knitting machines and can solve problems such as high yarn tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

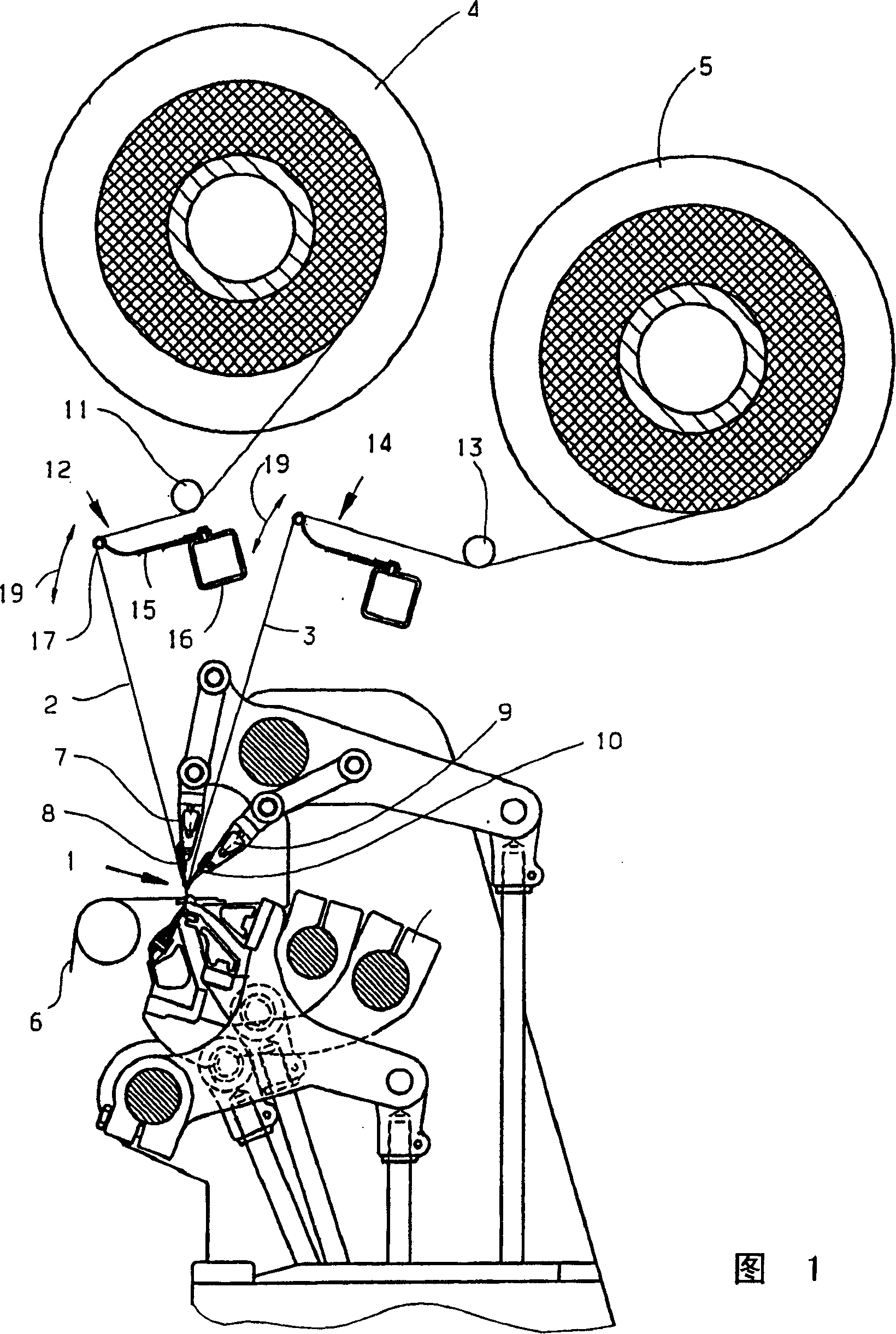

[0032] The warp knitting machine shown schematically and partially in Figure 1 has a knitting work area 1, and yarns 2, 3 are supplied to the knitting work area from warp beams 4 and 5, and the knitted fabric 6 woven from this work area is transported away. . The warp knitting machine has a comb device 7 with comb needles 8 and a comb device 9 with comb needles 10. Between the warp beam 4 and the bar needle 8, the yarn 2 is guided through a fixed guide tube 11 and a yarn tension device 12, on which the yarn is simultaneously deflected. In a similar manner, a guide tube 13 is arranged between the warp beam 5 and the bar needle 10, the guide tube is fixed, and a yarn tension device 14 is behind it. The above-mentioned two yarn tensioning devices are basically the same in structure. Therefore, only the yarn tension device 12 will be described in detail below.

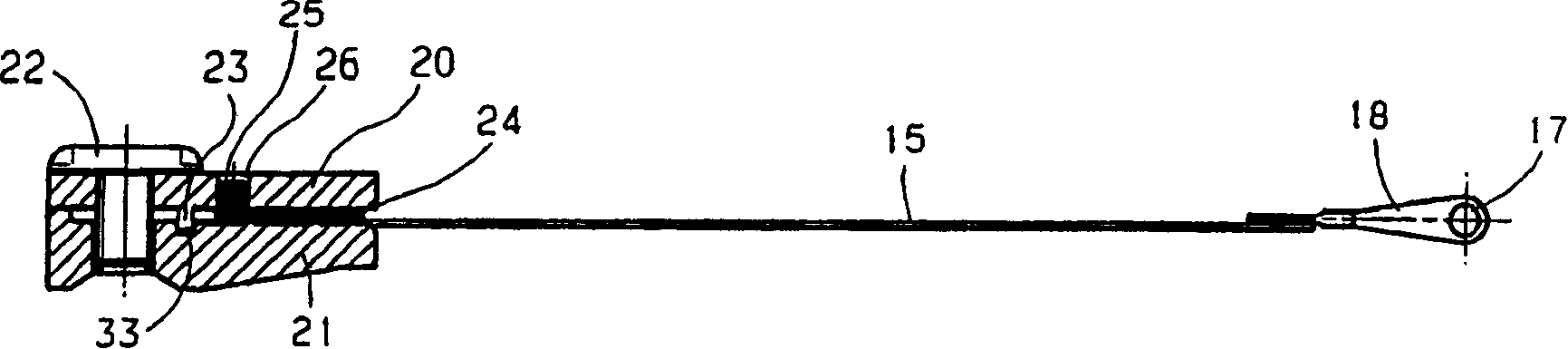

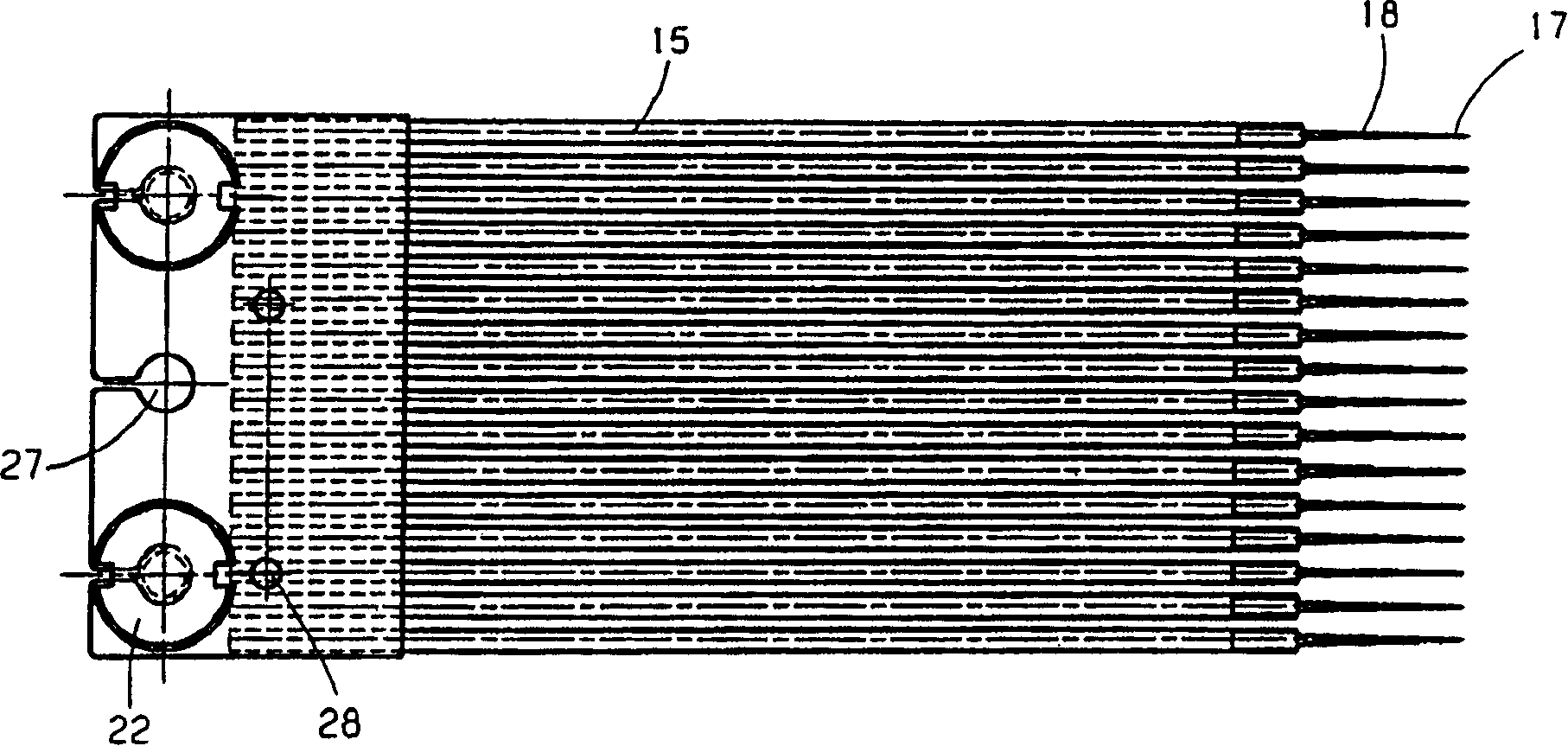

[0033] The yarn tensioning device 12 is equipped with a tension spring 15 for each of the yarns of the warp sheet 2, wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com