Component fastening assembly, component fastener and screw grommet

A technology of screw rings and components, applied in the direction of connecting components, thin plate connections, mechanical equipment, etc., can solve the problems of noise, rust and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

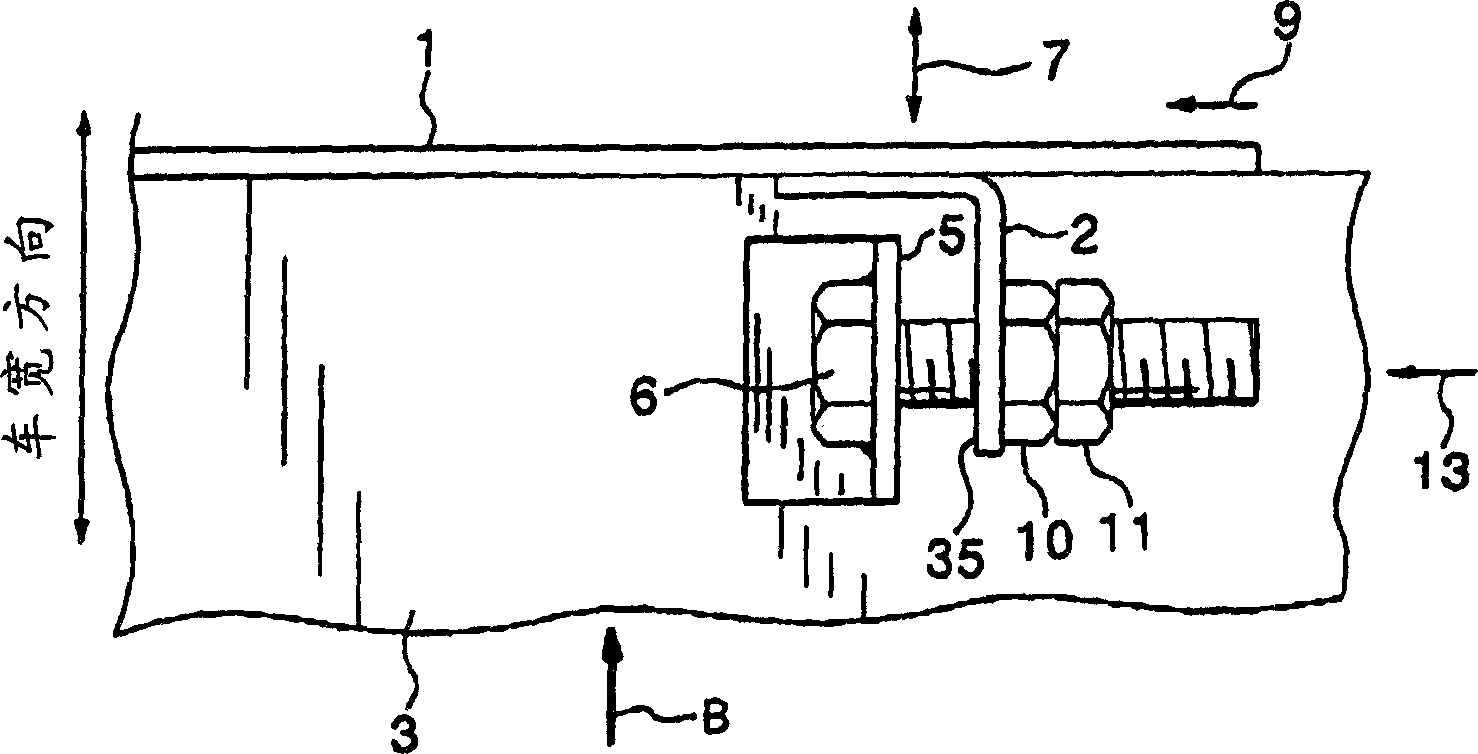

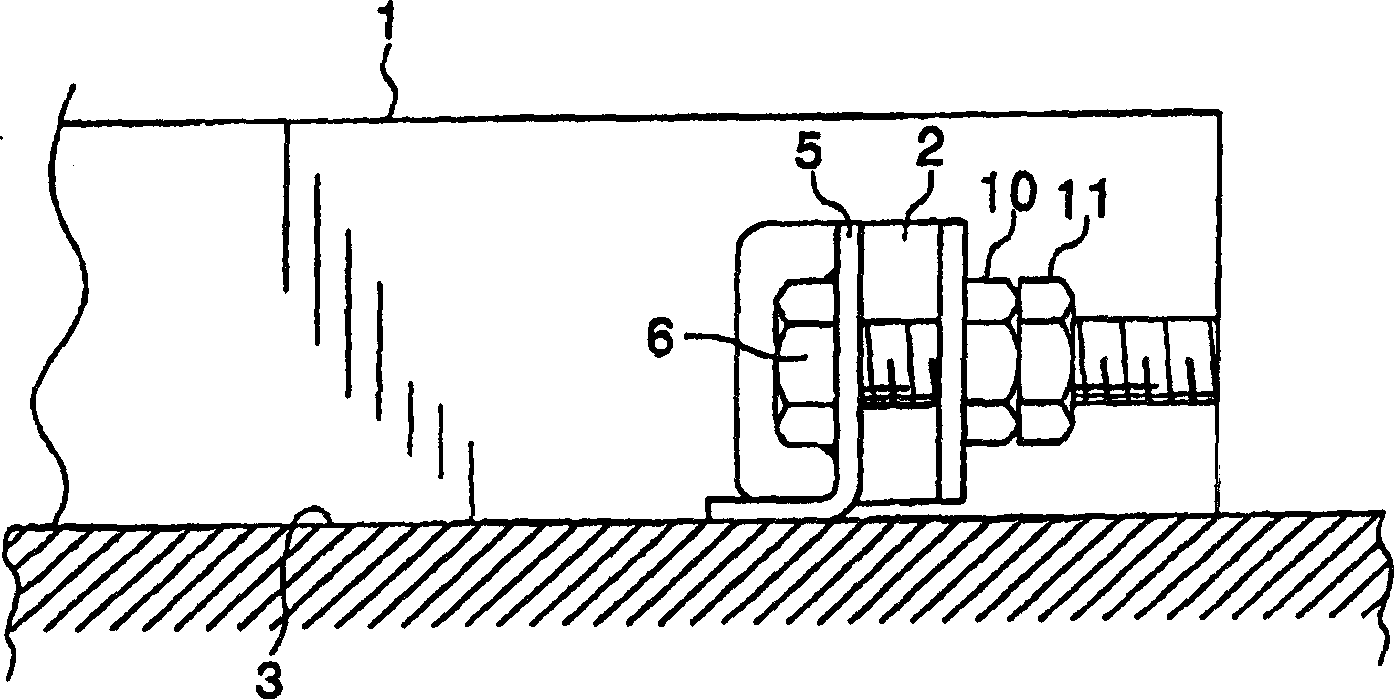

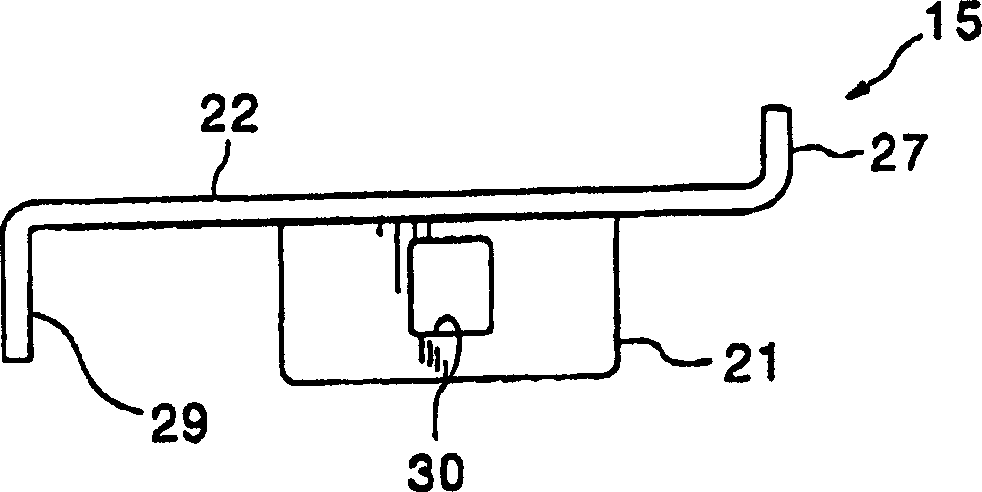

[0025] An embodiment of the present invention will now be described with reference to the drawings. In a component fastening device according to the present invention, a first L-shaped metal bracket 2, as shown in FIG. In addition to the first bracket 2, the component fastening device according to the invention comprises a second metal bracket 15, as Figures 2 to 4 As shown in it, it is installed on the automobile body as the workpiece, and the screw collar 17, as Figures 5 to 8 Manufactured as a single piece of synthetic resin as shown. The second workpiece holder 15 and the screw collar 17 constitute a part fastener of the part fastening device. Figures 9 to 11 A part fastener 18 is shown, in which the screw collar 17 is connected to a second support 15 which is fastened to the vehicle body 3 as workpiece. Figures 12 to 14 It is shown that the cover 1 is fastened as an attachment part to the vehicle body 3 as workpiece by means of fastening devices according to the in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap