Element making appts., its making method and electronic appts.

A technology for manufacturing devices and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, discharge tube/lamp manufacturing, inking devices, etc., and can solve problems such as inability to eject liquids, missing ink dots, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Next, the device manufacturing apparatus of the present invention will be described.

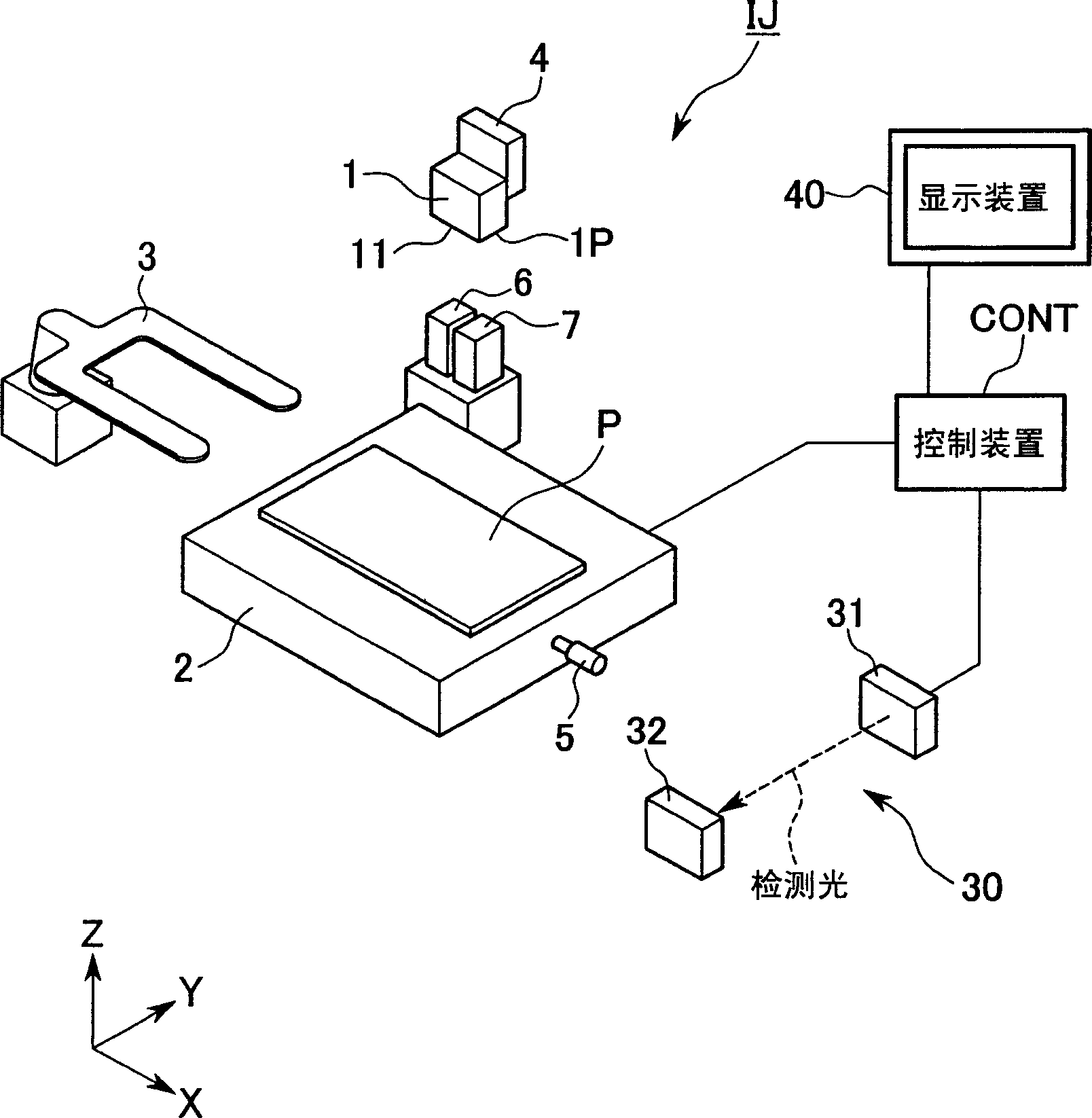

[0047] figure 1 It is a schematic perspective view showing an embodiment of the device manufacturing apparatus of the present invention.

[0048]The device manufacturing apparatus of this embodiment includes a droplet discharge device having a discharge head capable of discharging droplets of a liquid material (liquid) containing a functional material.

[0049] exist figure 1 Among them, the device manufacturing device (droplet ejection device) IJ has: a spray head 1 for ejecting liquid droplets of a liquid material, a table top device 2 for supporting a substrate P of a base material for manufacturing a device, and a substrate P is carried in and out ( loading and unloading) to the transport device 3 on the stage device 2, and the control device CONT for controlling the overall operation of the device manufacturing apparatus IJ including the discharge operation of the nozzle head 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com