Hole plug

A hole plug and head technology, applied to nuts, superstructure sub-assemblies, applications, etc., can solve problems such as unreliable insertion operations, and achieve the effects of easy insertion, restraining radial shrinkage, and improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

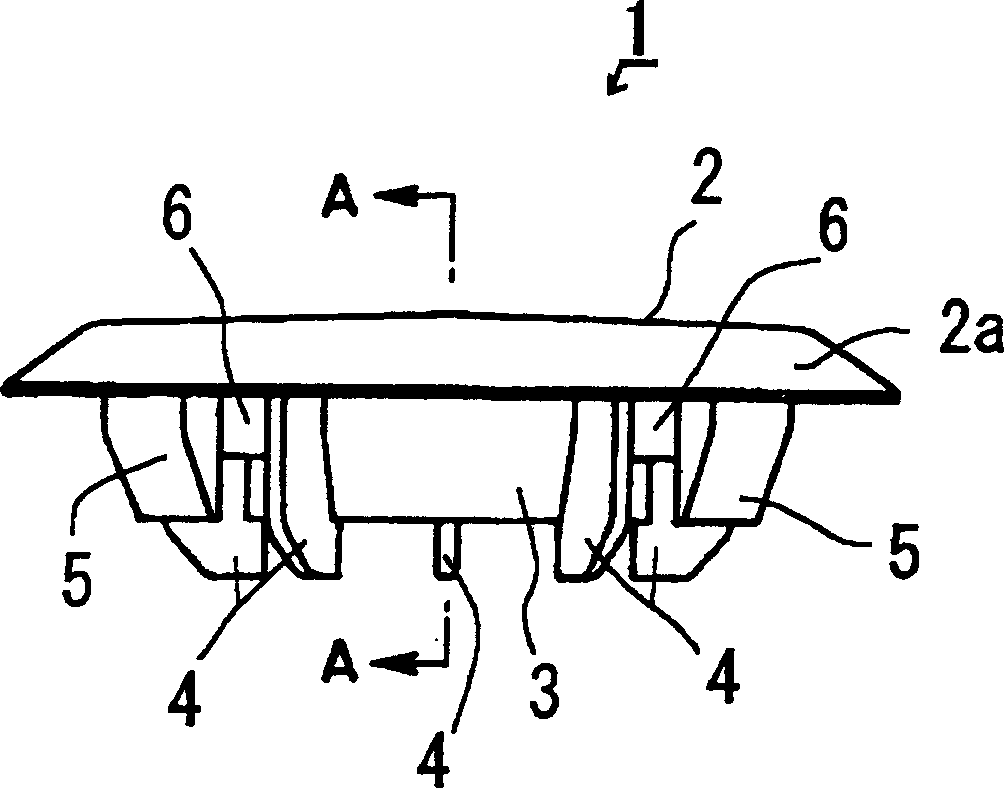

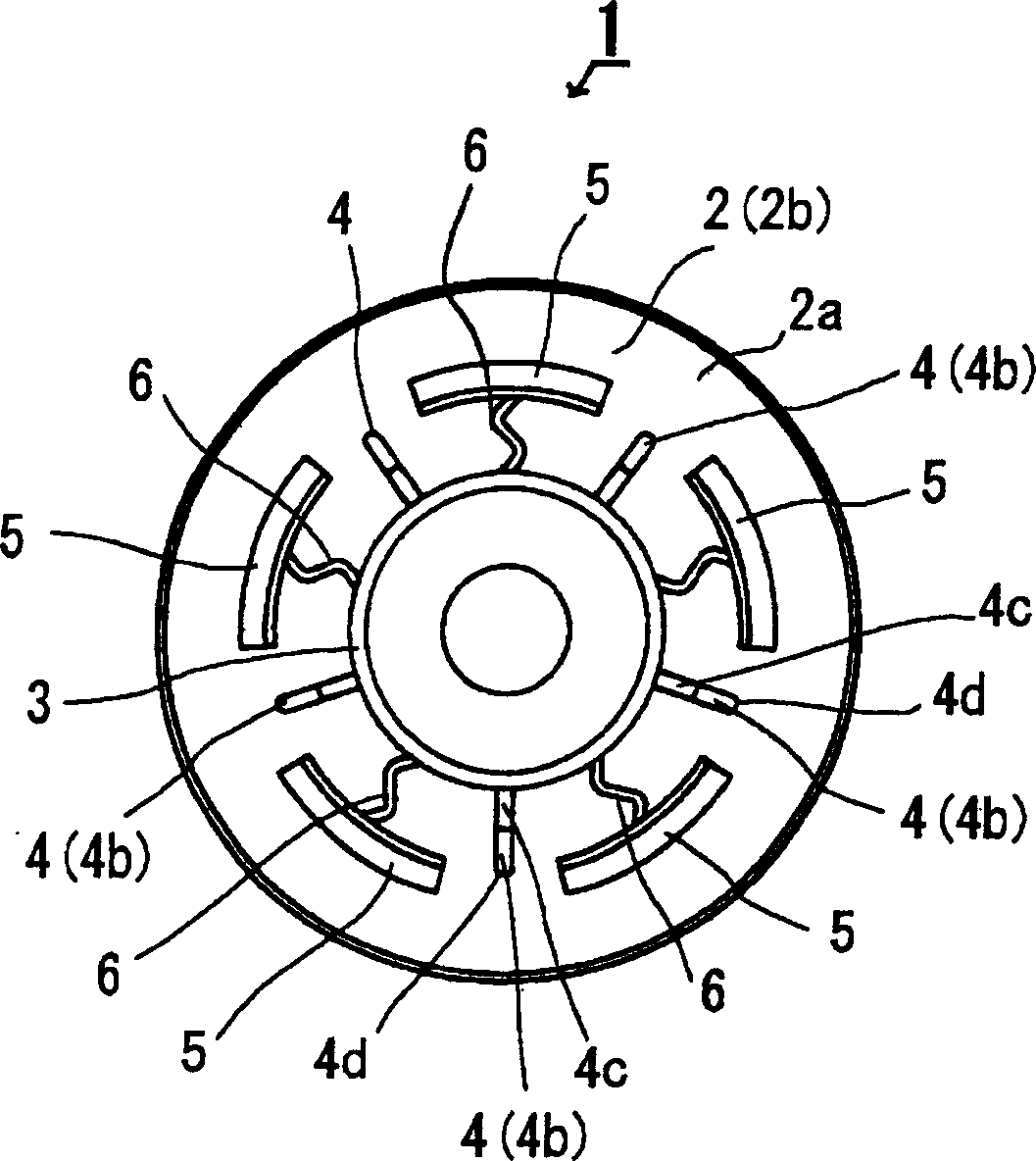

[0028] exist Figure 1 ~ Figure 4 Among them, symbol 1 is the hole plug of this embodiment, and the hole plug 1 has: a head 2, a pillar portion 3, a plurality of (5 in this embodiment) guide portions 4, and a plurality of foot portions. (5 in this embodiment) upright plate portions, a plurality of (5 in this embodiment) support portions 6 as support means, and these members 2 to 6 are integrally molded using synthetic resin such as polyethylene.

[0029] The head portion 2 is formed in a thin disc shape. Most of the head 2 is flat except for the peripheral portion 2a, which can be given elasticity by bending and is inclined toward the inner surface 2b side as it goes radially outward of the head 2.

[0030] The said pillar part 3 stands upright from the inner surface 2b of the said head part 2. As shown in FIG. The pillar portion 3 is formed in a cylindrical shape fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com