Dissociating apparatus for papermaking raw material and method for dissociating papermaking raw material

A raw material and dissociation technology, applied in the direction of raw material separation, textile and papermaking, fiber raw material processing, etc., can solve the problems of low efficiency, occupying a large installation space, and the length of the rotating drum 200 is large, so as to improve the dissociation effect and increase the dissociation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

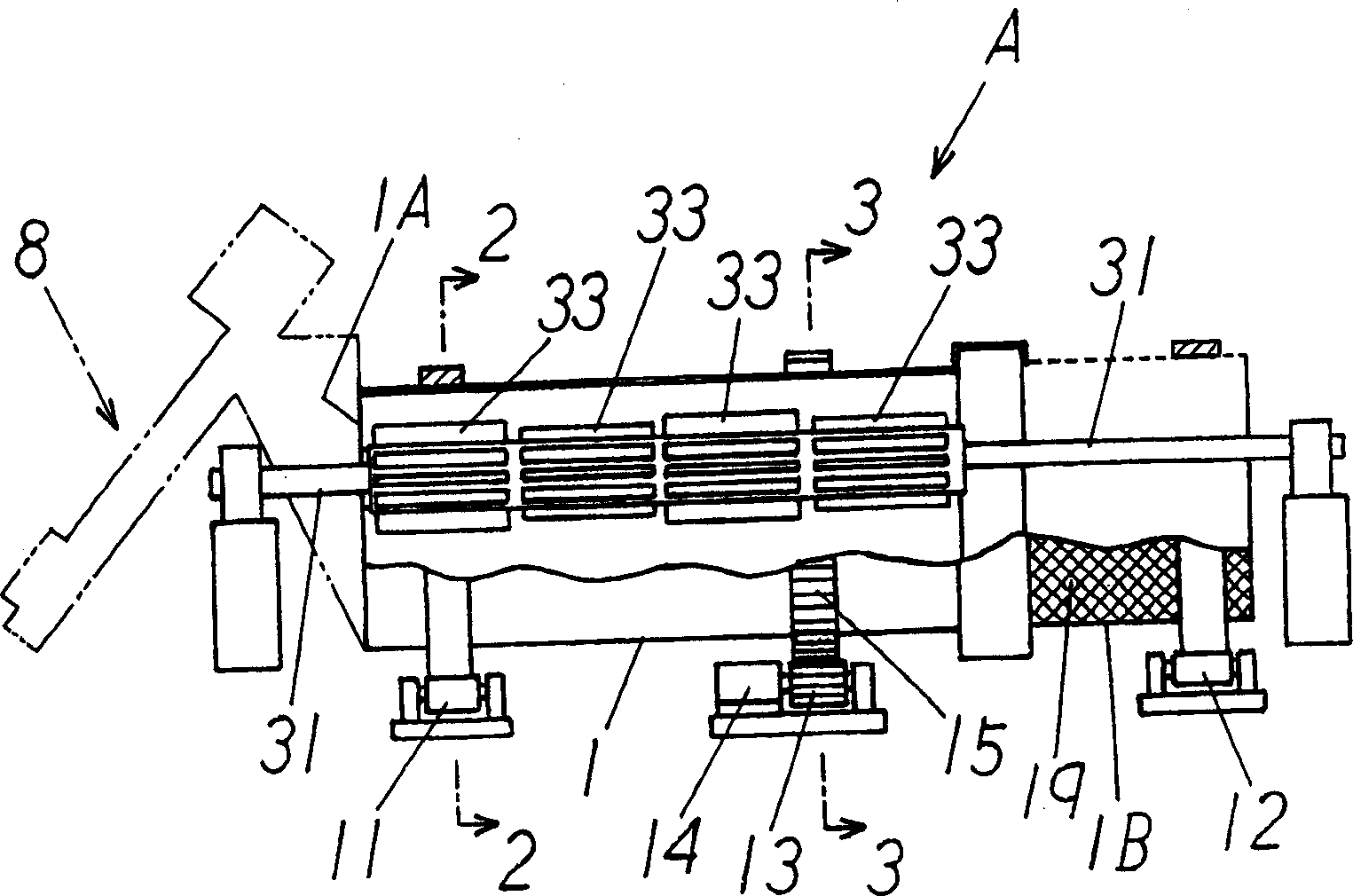

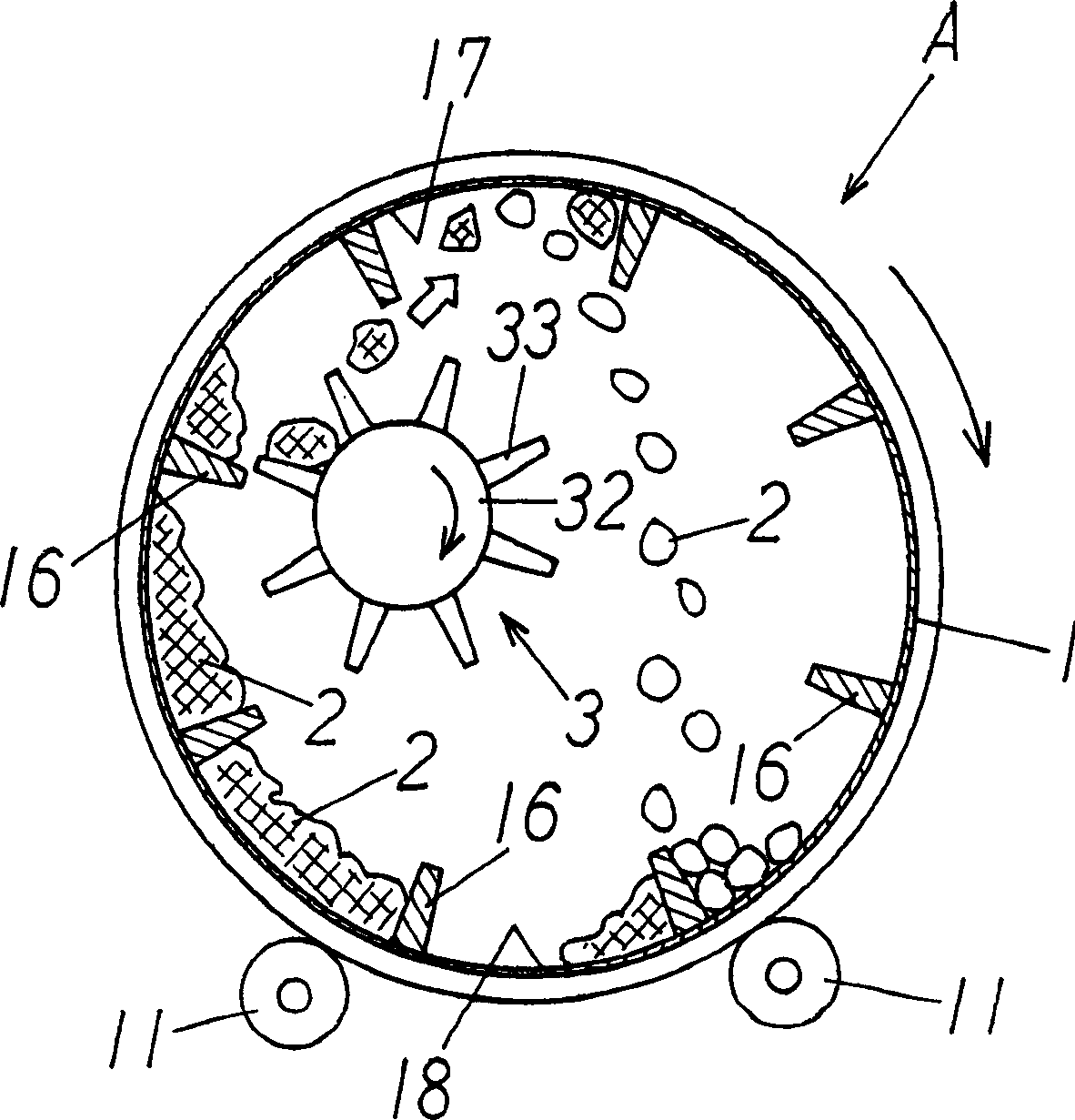

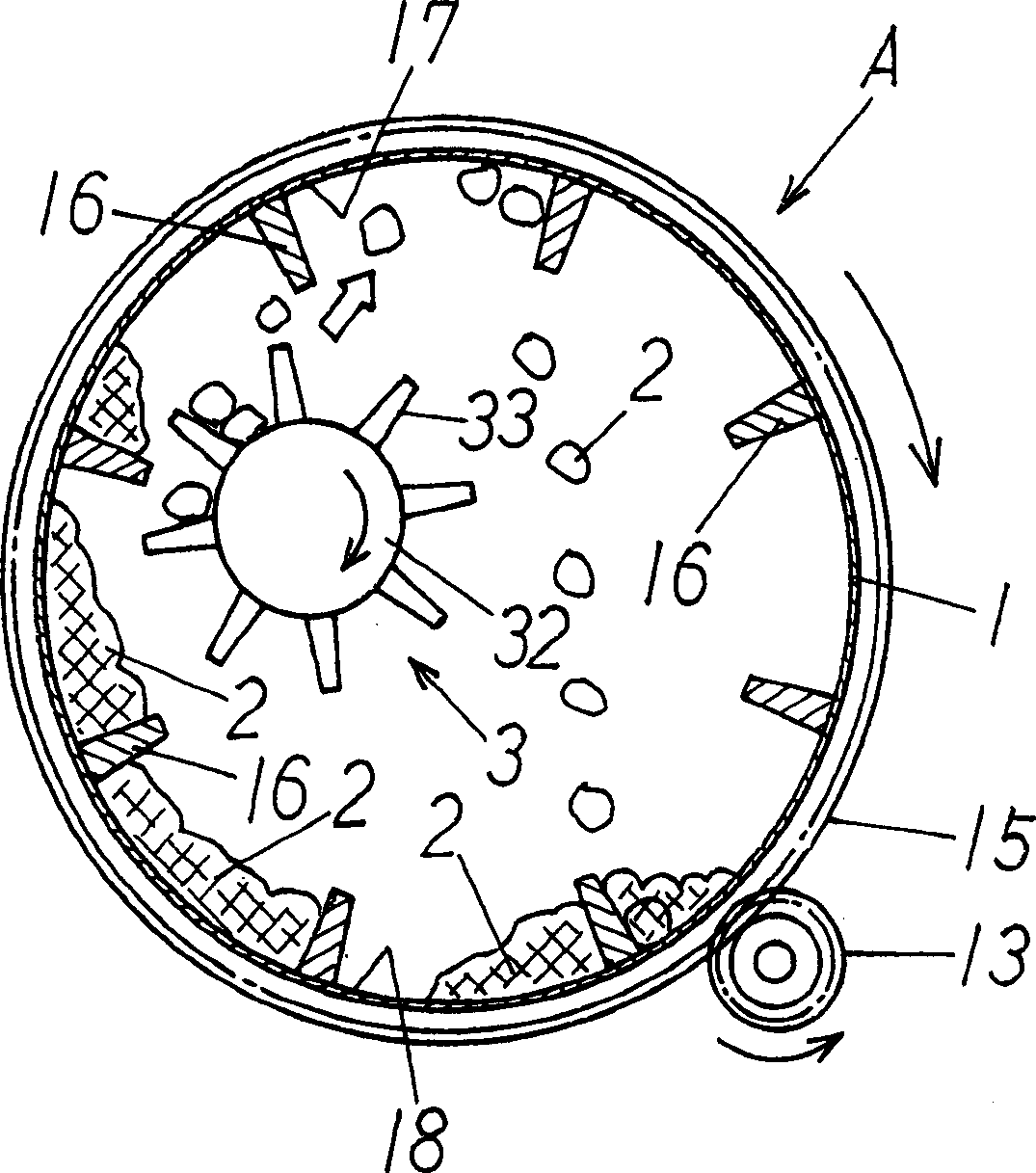

[0025] Next, an apparatus for disintegrating paper-making stock and a method for disintegrating paper-making stock according to an embodiment of the present invention will be described with reference to the accompanying drawings. exist Figure 1 to Figure 6 Among them, A is a dissociation device for papermaking raw materials, and the rotating drum 1 of the dissociation device A for papermaking raw materials is supported in a freely rotatable manner. 13 is supported for free rotation.

[0026] The driving roller 13 is driven by a motor 14 , and the driving roller 13 is provided with an engagement portion 15 that engages with the driving roller 13 provided on the outer periphery of the rotary drum 1 . Such as figure 2 and image 3 As shown, the driving roller 13 rotates counterclockwise, and the rotating drum 1 slowly rotates clockwise (for example, 10˜20 rpm).

[0027] On the rotary drum 1, a holding portion (for example, protrusion) 16 for holding the papermaking stock 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com