Electric power steering system

An electric power steering and steering system technology, which is applied to electric steering mechanisms, automatic steering control components, steering mechanisms, etc., can solve problems such as deterioration of steering feel, poor steering wheel return, and uneven steering feel, and achieve the goal of improving steering feel Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

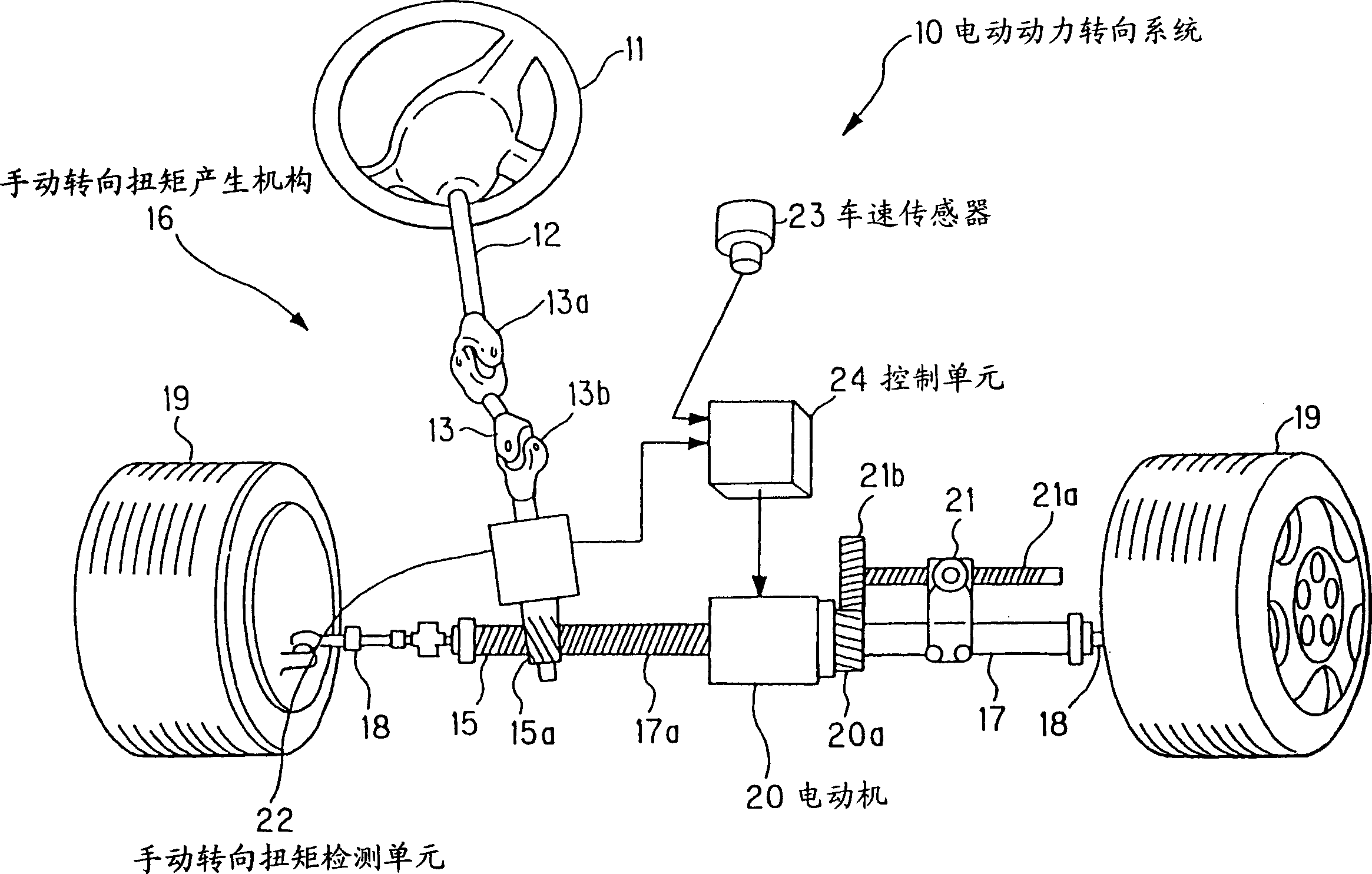

[0046] figure 1 is a diagram showing a typical configuration of an electric power steering system according to an embodiment of the present invention. In the electric power steering system 10, the manual steering torque generating mechanism 16 is formed by connecting the gear 15a of the rack-and-pinion transmission mechanism 15 with the steering shaft 12 integrally provided on the steering wheel 11 via the connecting shaft 13 having universal joints 13a, 13b. formed by connection.

[0047] The rack shaft 17 has rack teeth 17a meshed with the gear 15a, and when the rotational motion of the steering wheel is converted into reciprocating motion by the meshing of the gear 15a with the rack teeth 17a, the rack shaft 17 reciprocates, and the rack shaft 17 Its two ends are connected with the left and right front wheels 19 as turning wheels by steering tie ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com