Paper handling unit of ink-jet printer

A printer and paper discharge technology, applied in printing devices, printing, etc., can solve the problems of limited number of printable, minimum spacing cannot be maintained, image formation, etc., and achieve the effect of improving printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

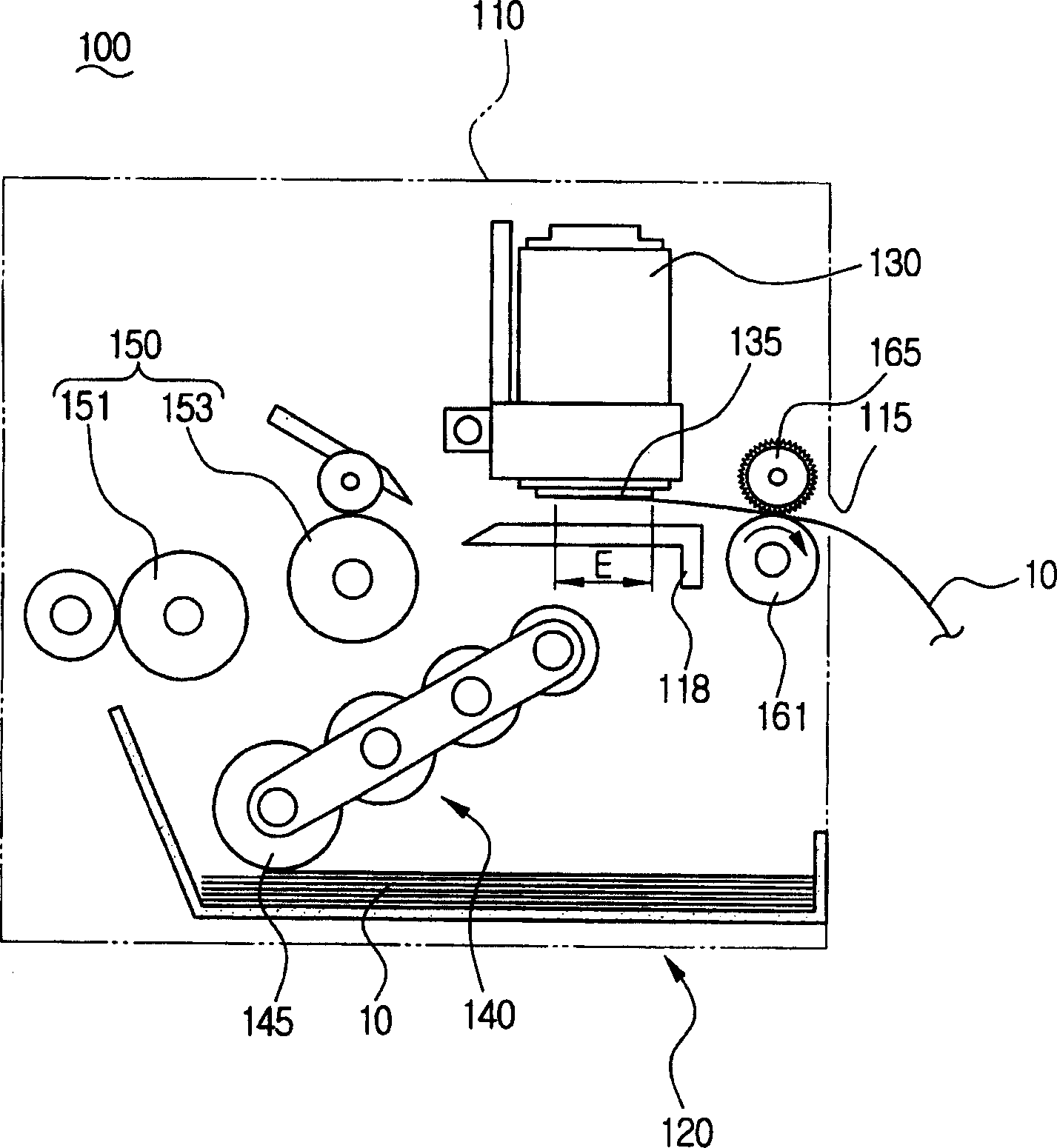

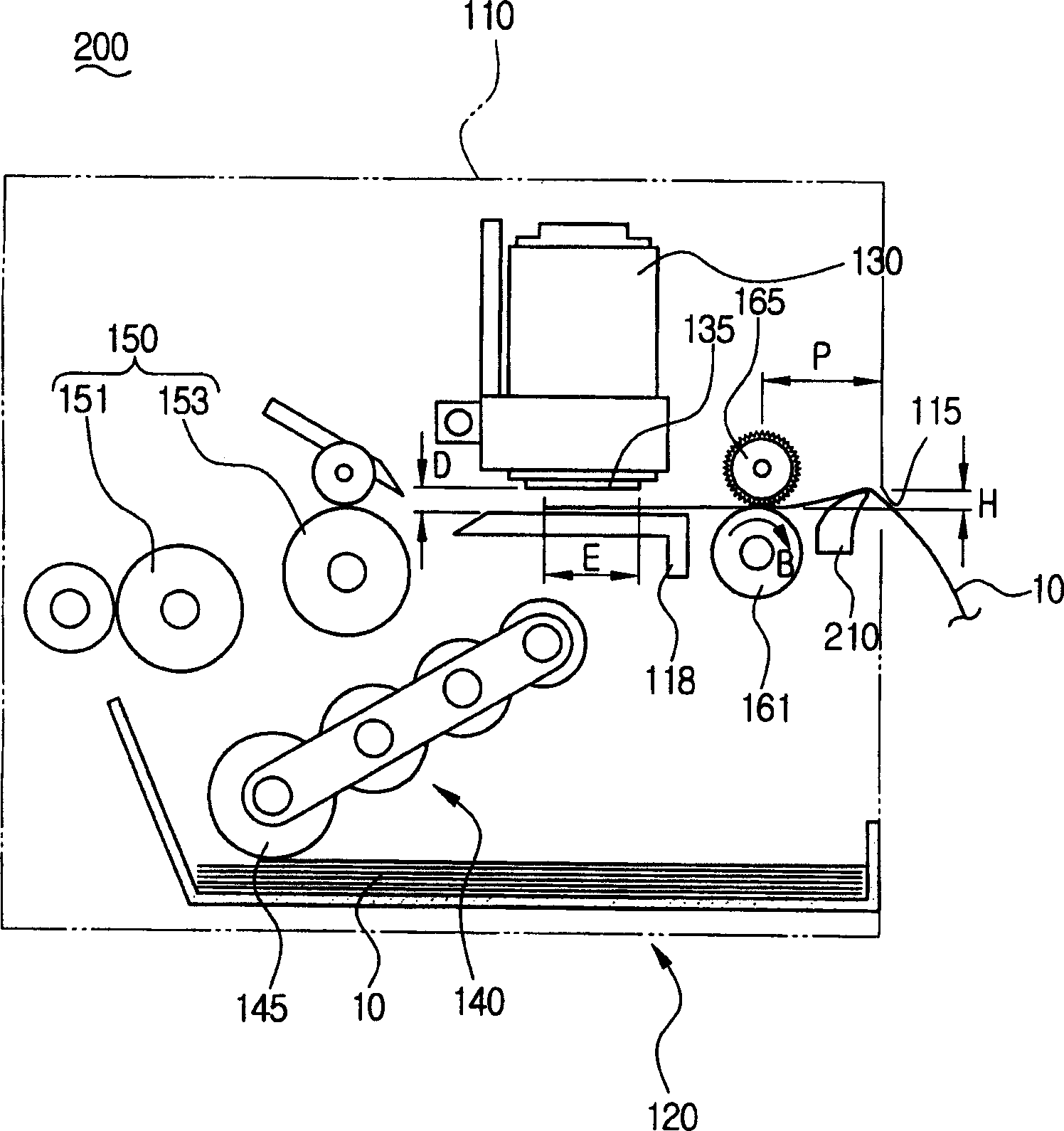

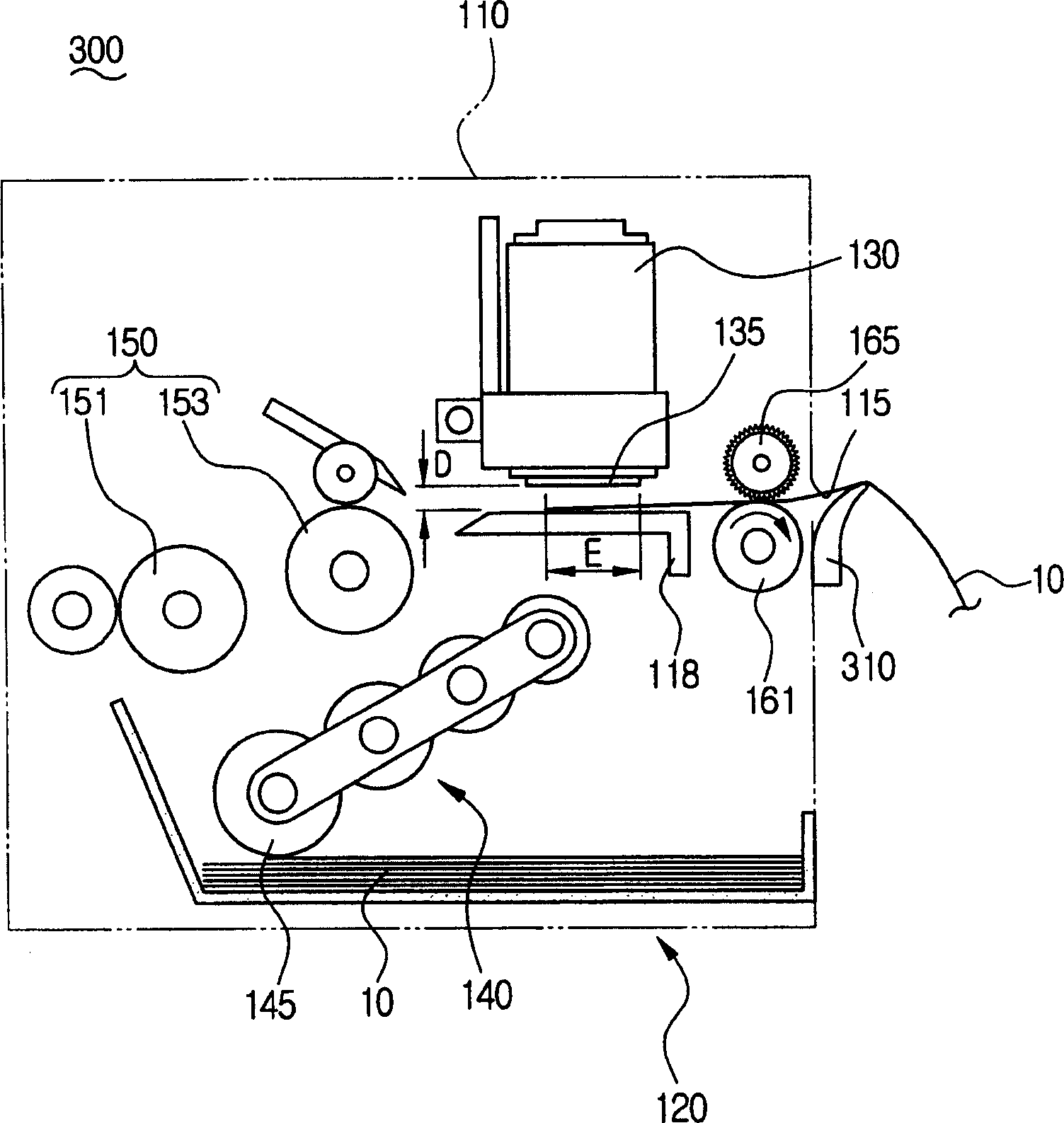

[0037] Preferred embodiments of the invention will now be described in detail, examples of which are illustrated in the accompanying drawings, in which like reference numerals refer to like elements. The embodiments are described below in order to explain the present invention by referring to the figures.

[0038] Such as figure 2 As shown, according to the first preferred embodiment of the present invention, the paper discharge unit of the inkjet printer 200 includes a paper discharge roller 161 and a paper discharge guide member 210. When the front end of the paper 10 just comes out of the paper discharge roller 161, said The paper discharge guide member just guides the front end of the paper 10 upward.

[0039] The paper discharge roller 161 is installed downstream of the ink cartridge 130 in the paper discharge direction, and is driven by a driving unit so as to be rotatable forward and backward. Hereinafter, forward rotation of the discharge roller 161 refers to rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com