Cloth feeding mechanism of sewing machine

A technology of cloth feeding mechanism and sewing machine, which is applied in the direction of cloth feeding mechanism, sewing machine components, sewing equipment, etc., and can solve the problems that the amount of cloth feeding does not reach the expected value, difficulty in adjustment, difficulty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] (Overall configuration of the embodiment)

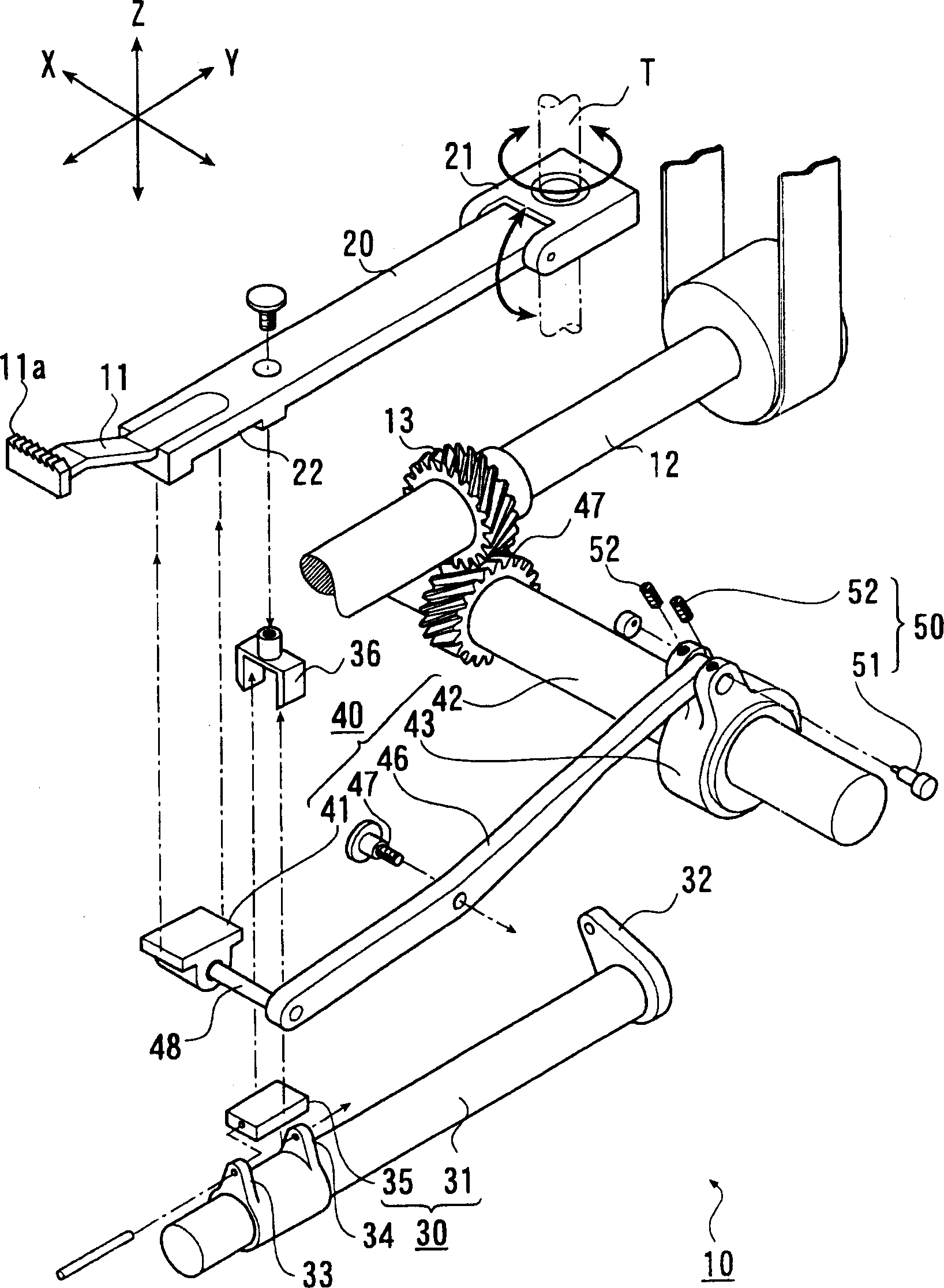

[0044] Below, refer to Figure 1 to Figure 5 Embodiments of the present invention are described. The lower feed mechanism 10 is mounted on, for example, a cylindrical sewing machine, and is a mechanism for feeding out the cloth on the throat plate in a predetermined direction by a predetermined feed amount.

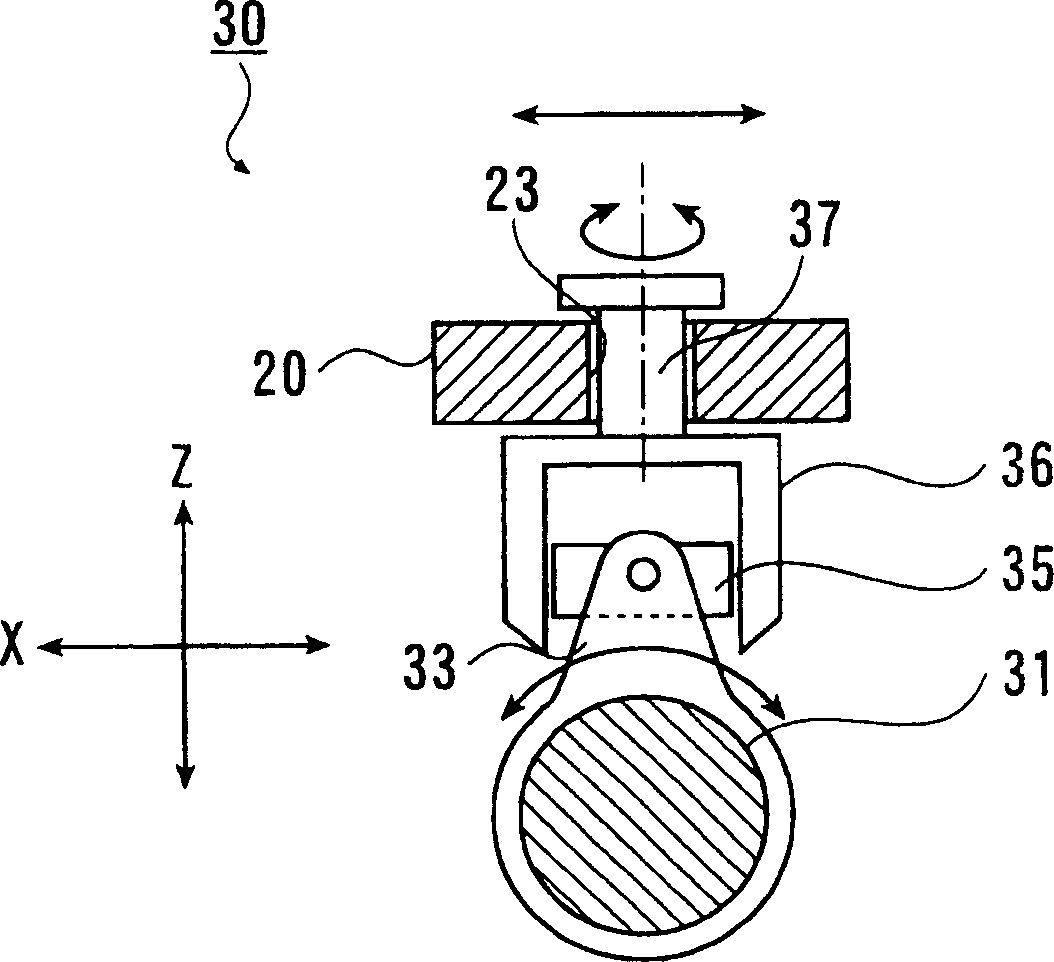

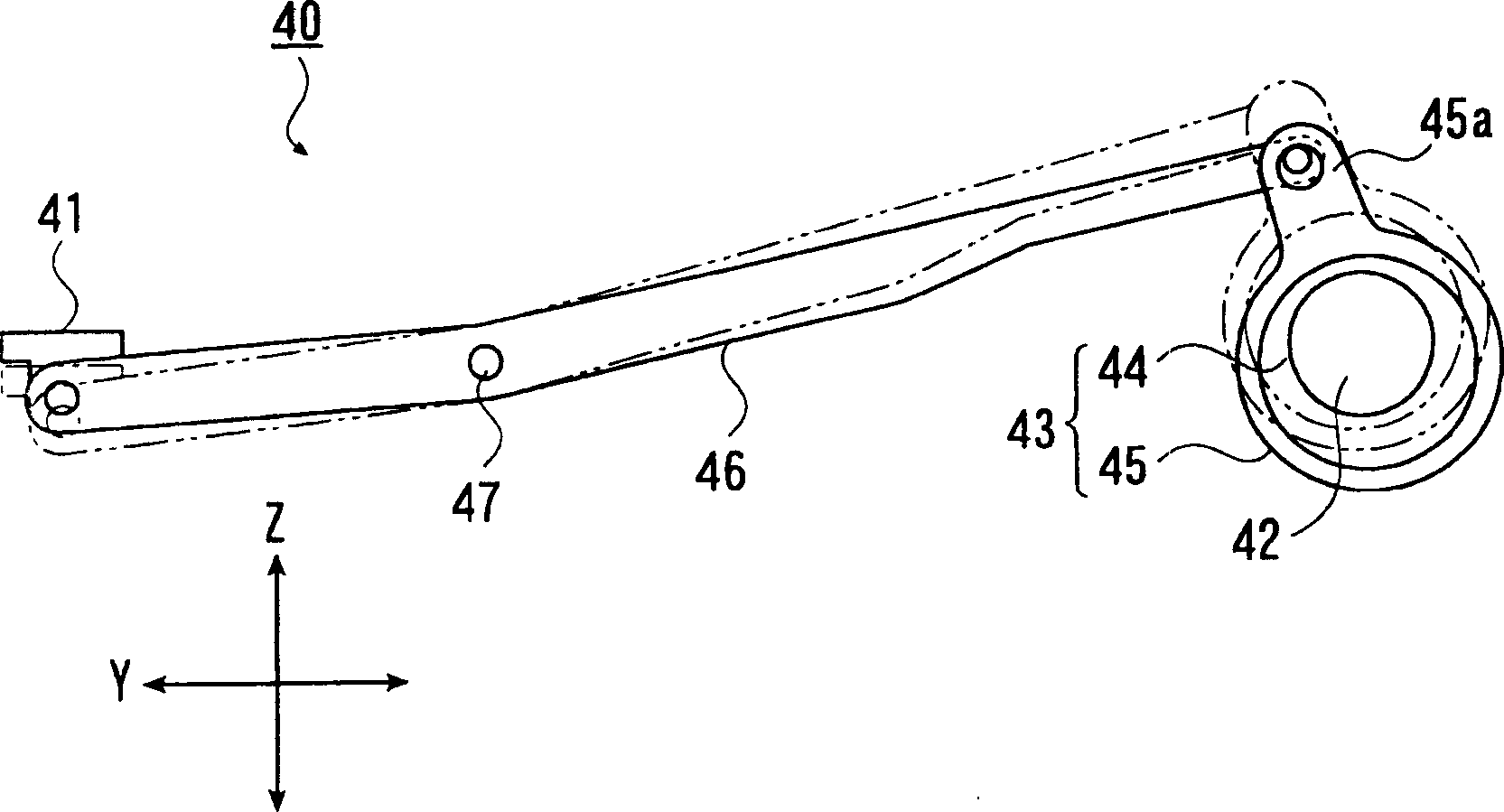

[0045] The cloth feed mechanism 10 of the sewing machine has serrated teeth 11a on its upper end surface, and includes a feed dog 11 that abuts the cloth from below a needle plate (not shown) and feeds it in a predetermined cloth feeding direction 2. The front end supports the feeding dog 11 and supports the end of the feeding rod 20 so as to swing in the up-down direction and the feeding direction. The feeding swing mechanism 30 makes the feeding rod 20 swing in the feeding direction. A vertical swing mechanism 40 for swinging the cloth rod 20 in the vertical direction, and a height adjustment mechanism 50 for adjustin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com