Wave distribution board of speedboat yacht

A wave splitter and speedboat technology, applied in the direction of ships, hydrodynamic characteristics/hydrostatic characteristics, hulls, etc., can solve the problems of hindering the high-speed advancement of the hull, consuming the forward power of the hull, etc. Practical and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention is described in further detail with preferred embodiment:

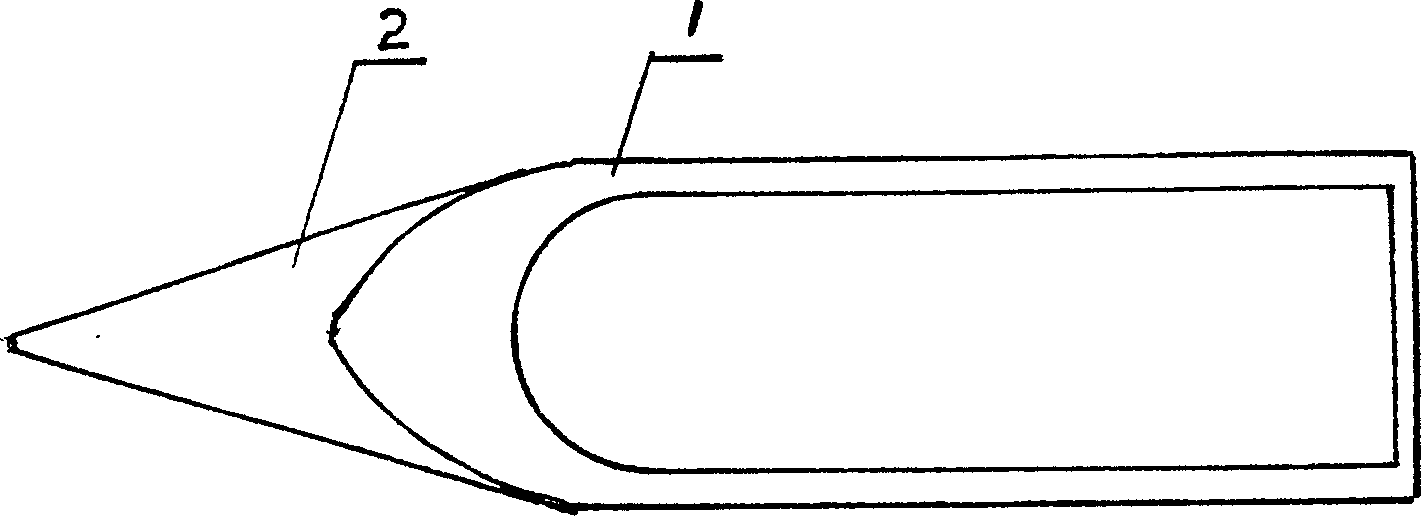

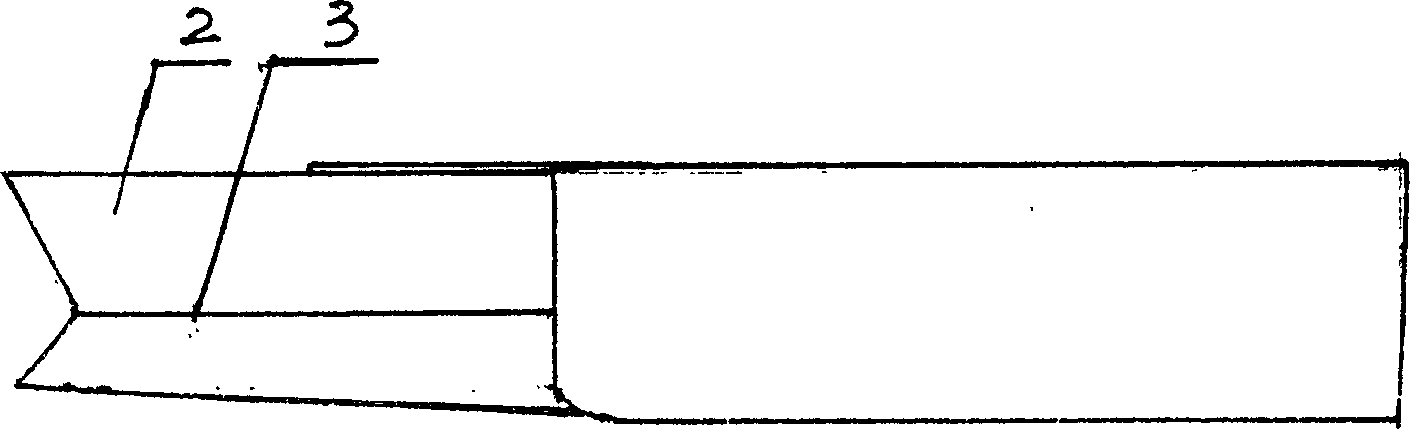

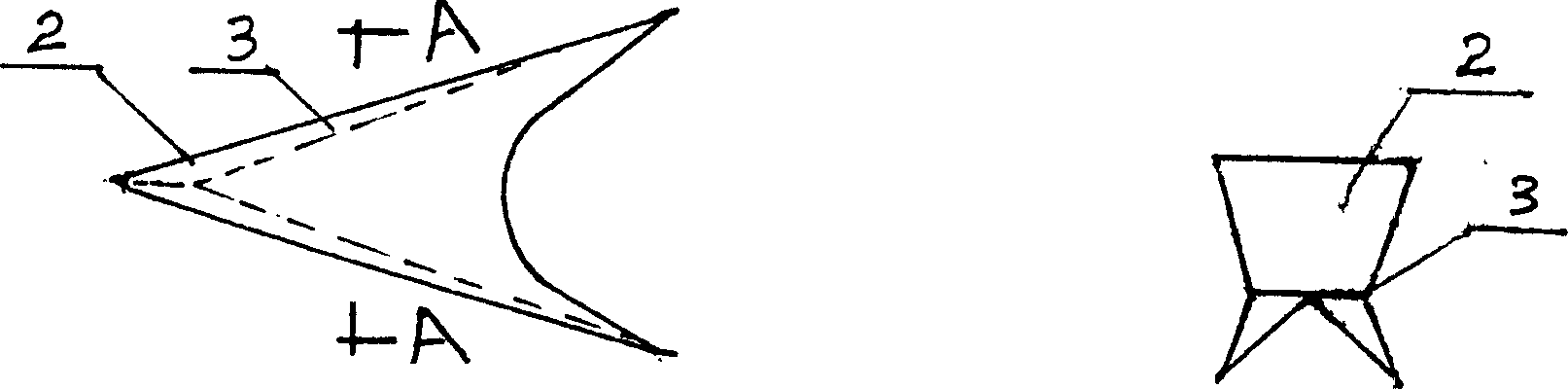

[0014] The present invention is a triangular integral wave splitter (2) fixedly arranged on the front part of the hull (1). 1) fixedly connected, triangular push plates (4) are provided on both sides of the water line (3) bottom of the wave splitter (2). When the hull is running fast in the water, the two side push plates (4) at the bottom of the waterline of the wave splitter (3) separate the waves from the middle in the water, and the waves on the side are slightly stirred up by the inclined plane and separated to the two sides. Reach the purpose that the hull is like running on calm water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com