High frequency component and installation structure thereof

A component and high-frequency technology, applied in the field of high-frequency components and their installation structures, can solve the problems of inability to achieve thinning, inability to achieve lightweight, and cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

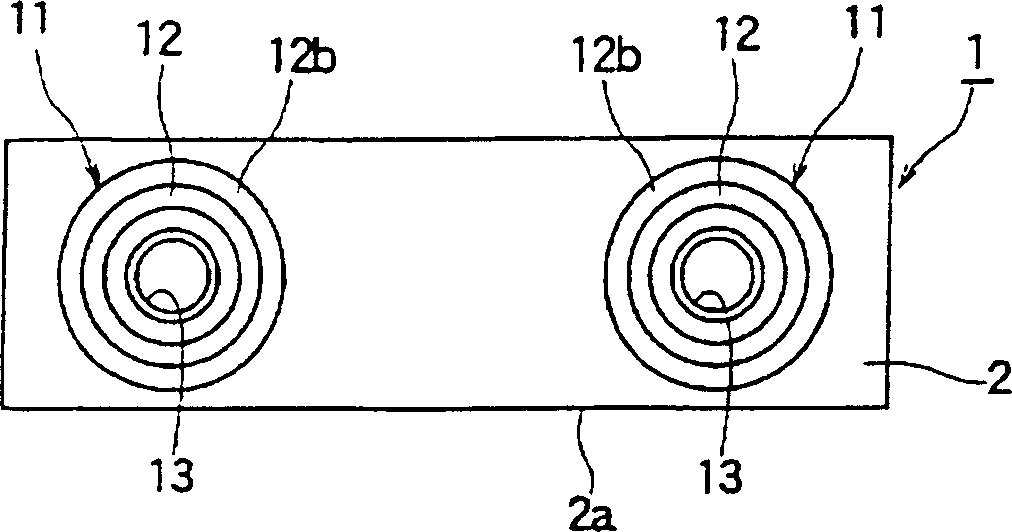

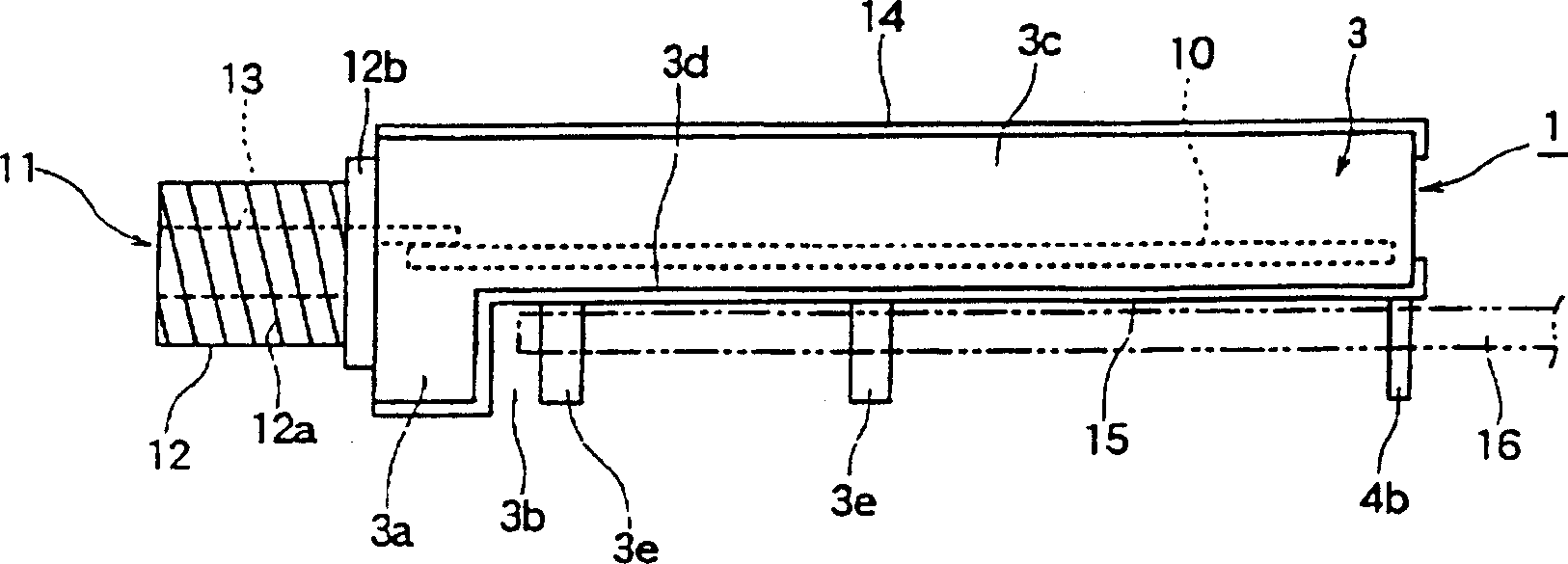

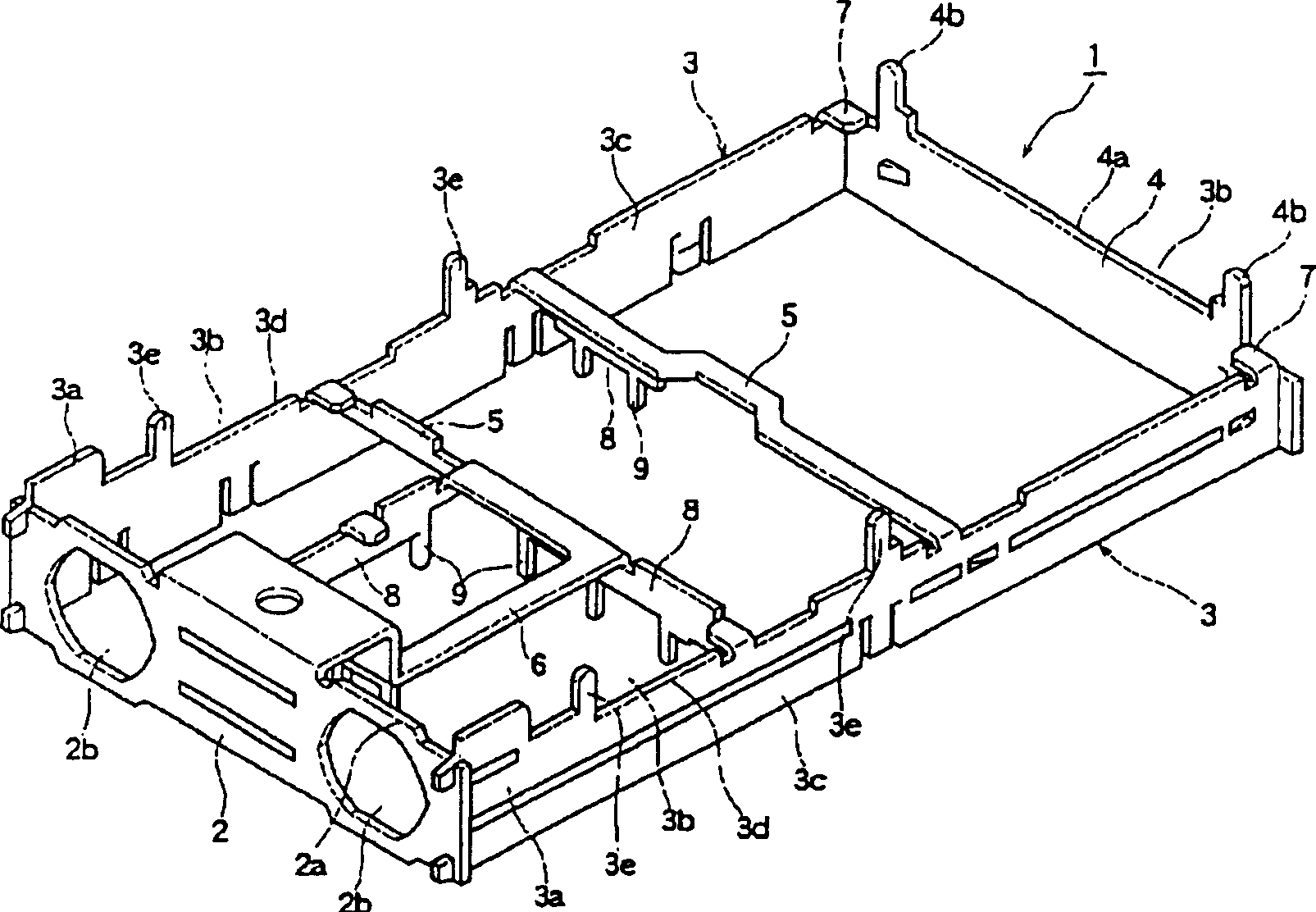

[0030] Below, a schematic diagram illustrating the high-frequency component of the present invention and its installation structure, figure 1 It is a front view showing the first embodiment of the high-frequency module of the present invention. figure 2 It is a side view showing the first embodiment of the high-frequency module of the present invention and its mounting structure. image 3 It is a perspective view showing a state in which the housing is turned upside down in the first embodiment of the high-frequency module of the present invention. Fig. 4 is an explanatory diagram showing a method of manufacturing a frame of the first embodiment of the high-frequency module of the present invention.

[0031] 5 is a perspective view showing a housing according to a second embodiment of the high-frequency module of the present invention. Figure 6 It is an explanatory drawing showing the manufacturing method of the housing according to the second embodiment of the high-freque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com