Electric valve

A technology of electric valves and valve bodies, which is applied in the direction of lifting valves, valve devices, valve details, etc., and can solve problems such as impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

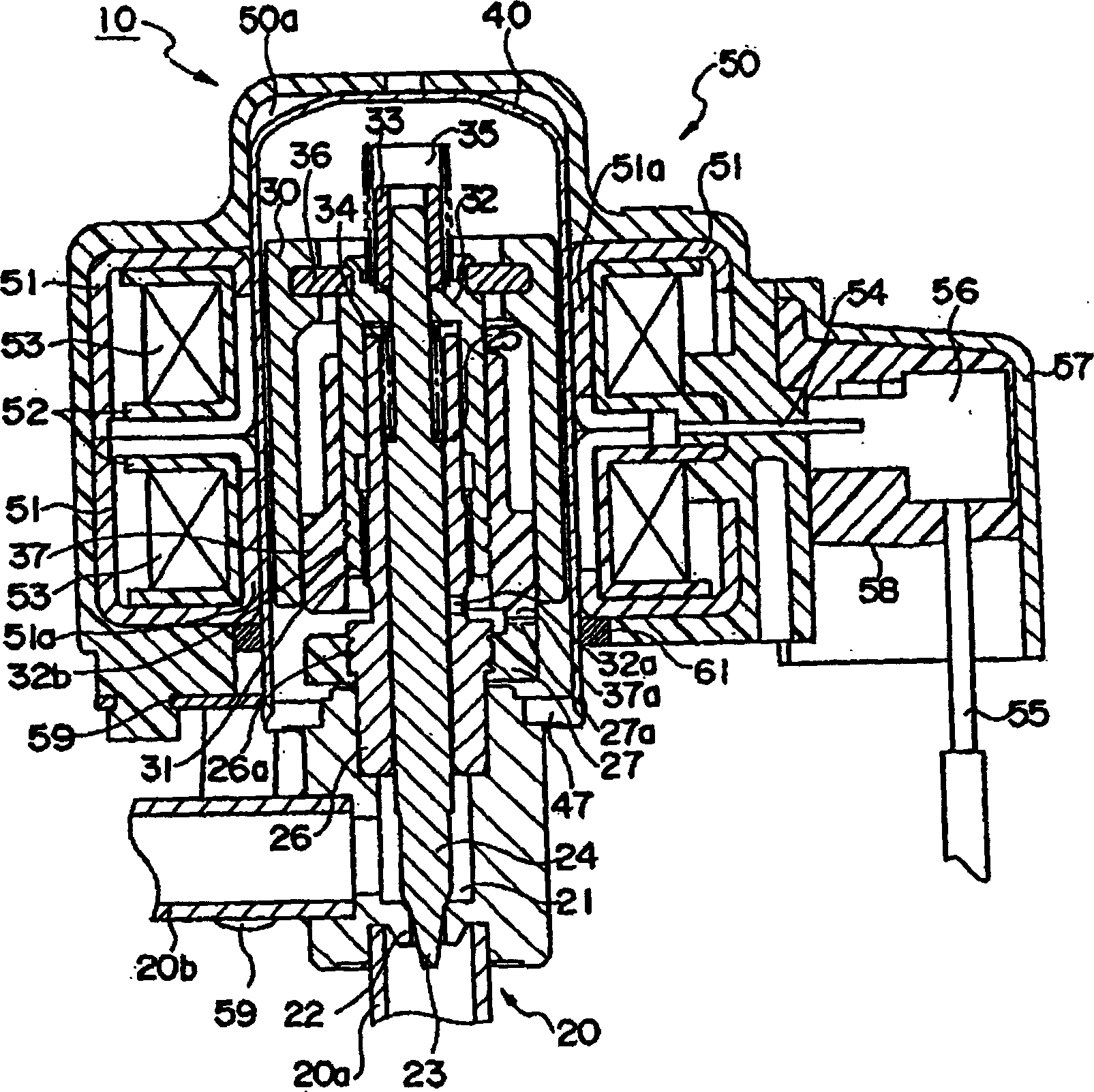

[0028] Embodiments of the electric valve of the present invention will be described in detail below with reference to the accompanying drawings. figure 1 It is a longitudinal sectional view of the electric valve of the first embodiment of the present invention. In this figure, the same components as those of the conventional motor-driven valve shown in FIG. 4 are denoted by the same reference numerals, and description thereof will be omitted. In the first embodiment, a conductive ring 61 made of brass, for example, is fitted on the outer periphery of the case 40 , and the conductive ring 61 is brought into contact with the yoke 51 of the stator 50 . In this way, since the yoke 51 is connected to the valve main body 20 through the conductive ring 61 and the shell 40, even if high-voltage noise is added to the stator coil 53, the discharge generated between the yoke 51 and the shell 40 can be suppressed, and the impact on the yoke 51 can be reduced. effects on surrounding circu...

no. 2 Embodiment

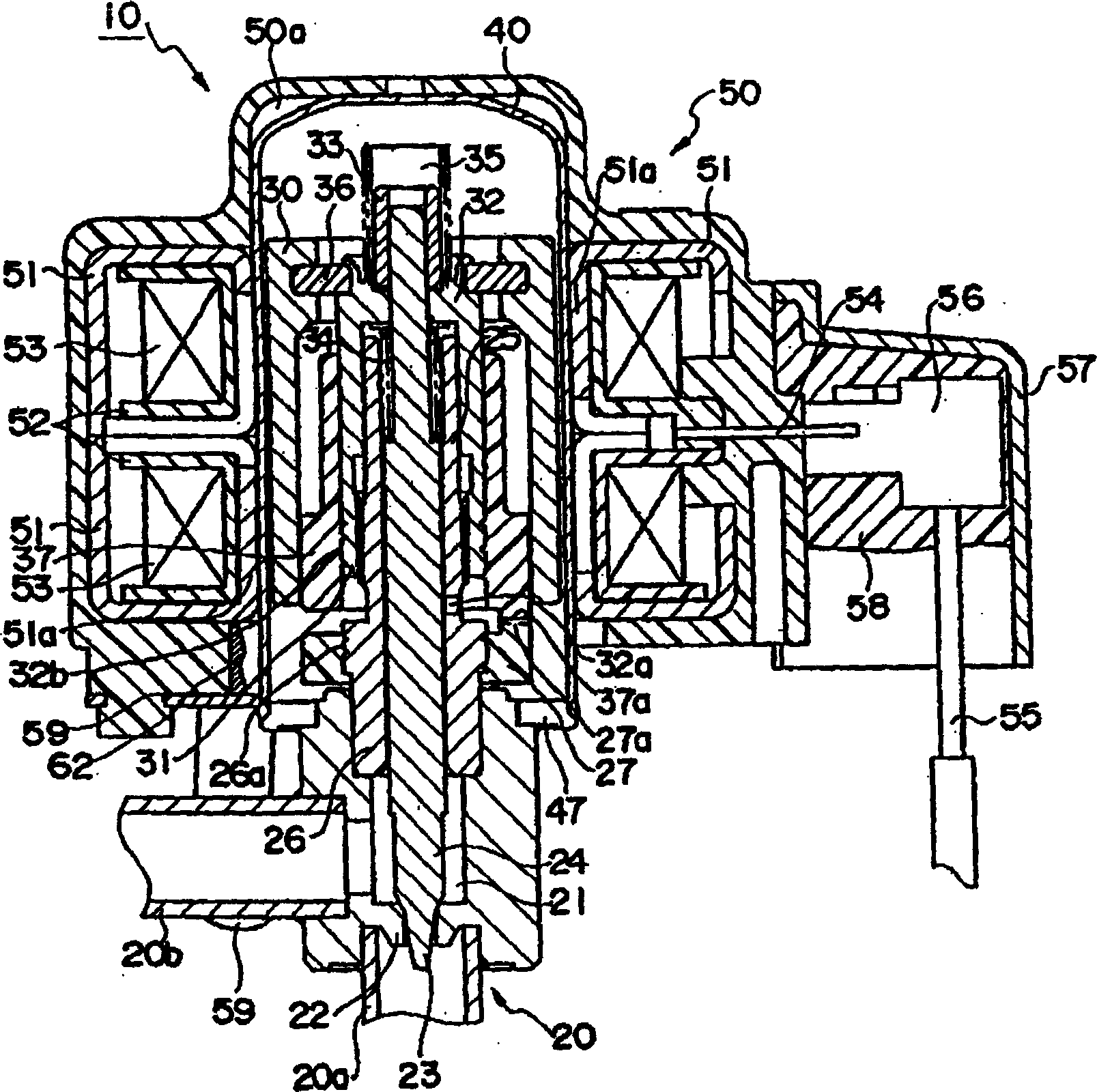

[0030] use figure 2 The structure of the electric valve of the second embodiment of the present invention will be described. In this figure, the same components as those of the conventional electric valve shown in FIG. 4 are given the same reference numerals, and their descriptions are omitted. In this embodiment, the valve body 20 and the yoke 51 are connected using a conductive resin 62 . That is, in this embodiment, the anti-rotation member 59 and the yoke 51 that fix the stator 50 to the case 40 non-rotatably are connected using the conductive resin 62 . Since the anti-rotation member 59 is connected to the fluid lead-out pipe 20b attached to the valve main body 20, similar to the first embodiment, even if high-voltage noise is added to the stator coil 53, the noise generated between the yoke 51 and the case 40 can be suppressed. Discharge can reduce the impact on the surrounding circuit.

no. 3 Embodiment

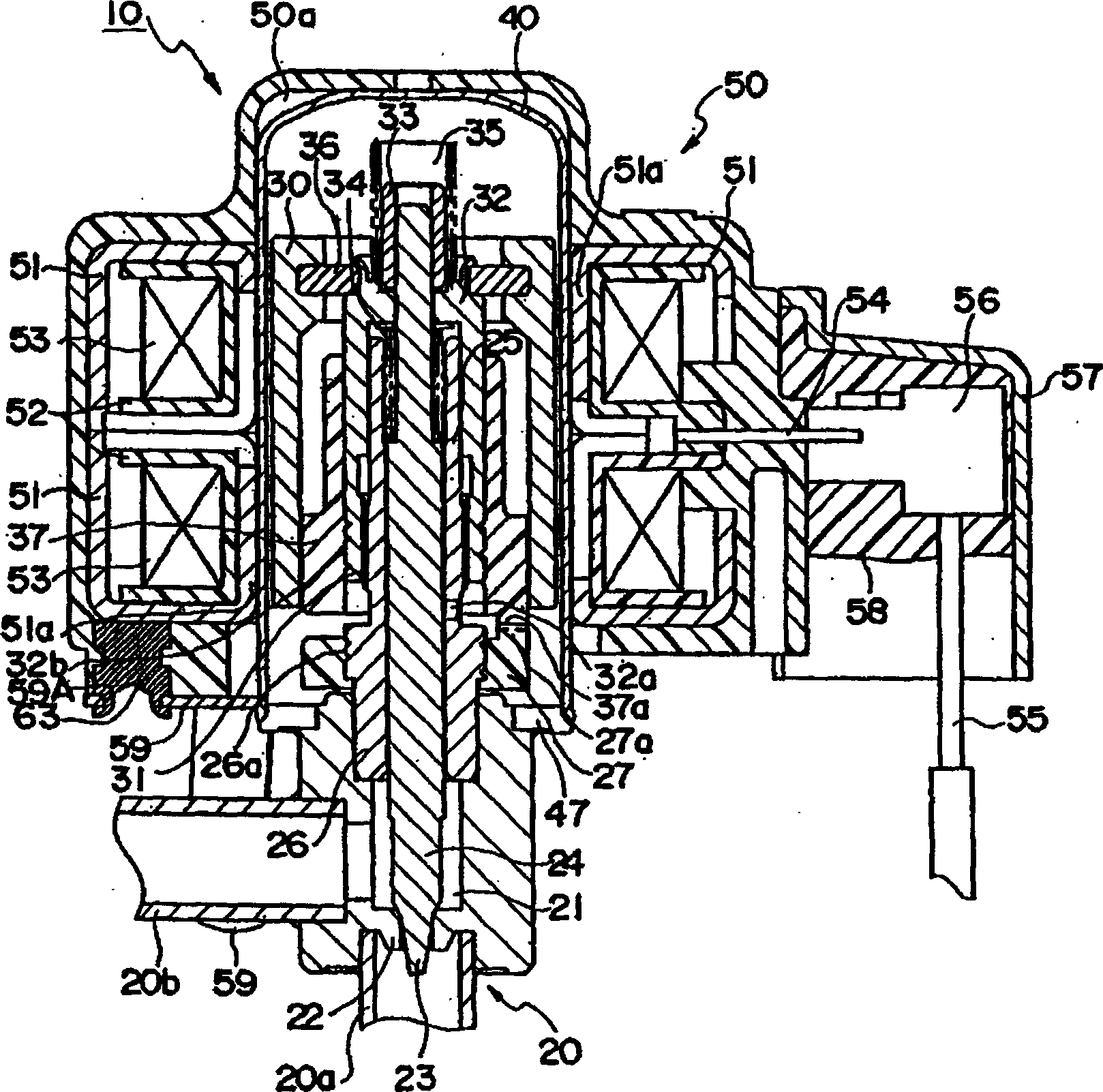

[0032] use image 3 The structure of an electric valve according to a third embodiment of the present invention will be described. In this figure, the same components as those of the conventional electric valve shown in FIG. 4 are given the same reference numerals, and their descriptions are omitted. In this embodiment, the valve body 20 and the yoke 51 are connected by a conductive fixing pin 63 made of conductive material. That is, in this embodiment, the anti-rotation member 59 and the yoke 51 that fix the stator 50 to the case 40 in a non-rotatable manner are connected using, for example, brass conductive fixing pins 63 . Since the anti-rotation member 59 is connected to the fluid outlet pipe 20b, similar to the first embodiment, even if high-voltage noise is added to the stator coil 53, the discharge generated between the yoke 51 and the case 40 can be suppressed, and the impact on the surrounding environment can be reduced. circuit effects.

[0033] As a method of pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com