Method of determining cord hardness and testing stand

A technology for testing racks and cords, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., which can solve the problems that easily cause disputes, cannot quantitatively reflect the actual level of cord hardness, etc., and achieve the test conditions and simple operation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

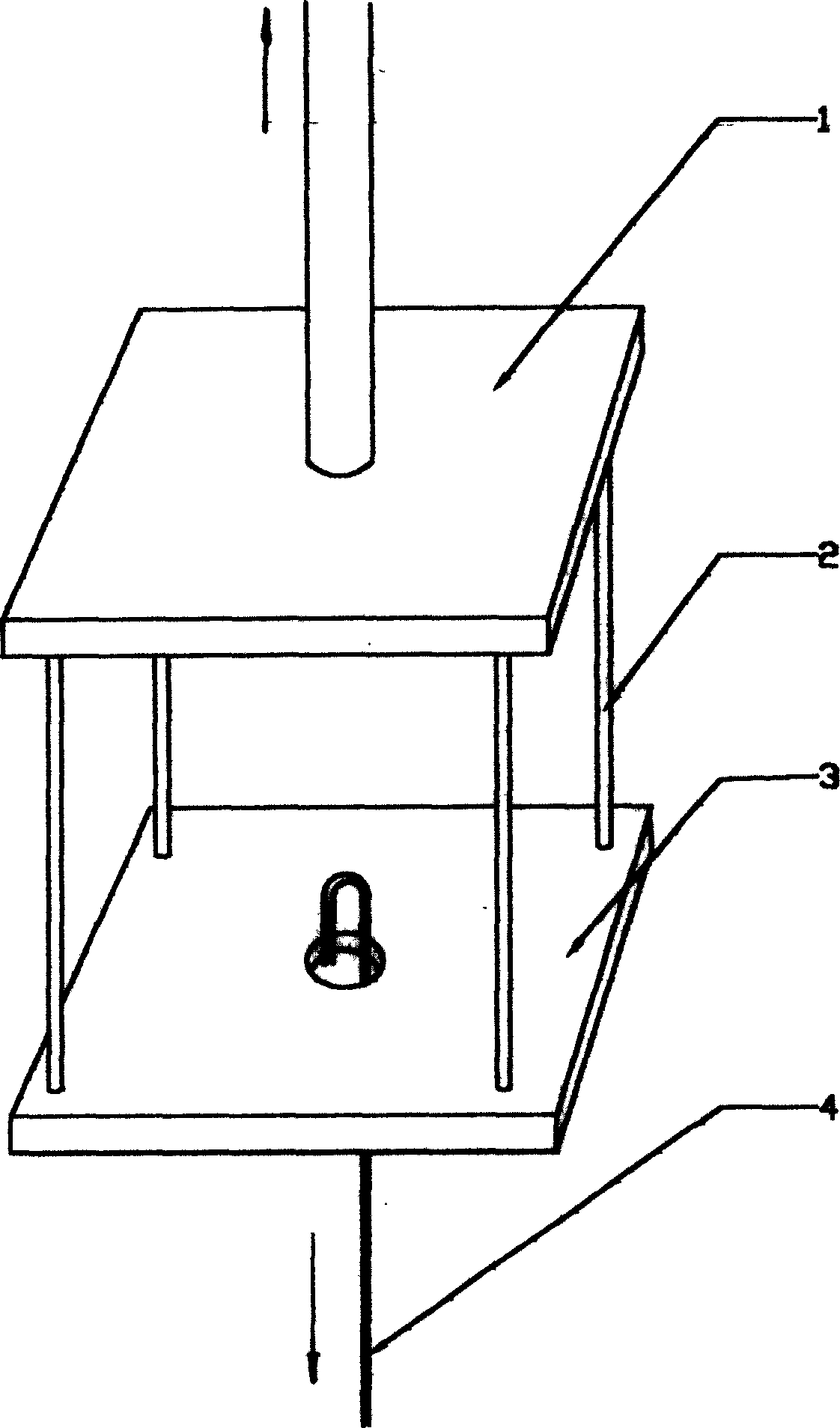

[0011] The following is a detailed description of the measurement process for measuring the hardness of the dipped cord: choose a 50N sensor, install the special hardness test frame on the upper and lower fixtures of the strength machine, and set the parameters of the strength machine as: speed 50mm / min, and then cut 2CM One long 930dtex / 2 nylon 6 dipped cord, put the cord lightly on the hole of plate 3, and pass through the center of the wire hook vertically at the same time, then start the power machine to draw down, wait for the power machine After the drafting is reset, the maximum drafting force, which is the hardness of the cord, is read out on the display of the strength machine.

Embodiment 2

[0013] The special test stand used in the present invention is composed of two square flat plates 1 and 3 with round holes and their four supporting columns 2 and metal wires 4. The square plates 1 and 3 and their four supporting columns 2 are connected with an adhesive material. into a dedicated test stand.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com