Method for rapidly determining content of free acid in lithium hexafluorophosphate electrolyte by coulometric titration digital end-point method

A technology for lithium hexafluorophosphate and coulomb titration, which is applied in the fields of analysis and detection and battery electrolyte, can solve the problems of unsuitable electrolyte lithium salt and electrolyte sample determination, complicated titration process and need to be carried out step by step, unfavorable for popularization, etc., to meet the requirements of industrialization. Production requirements, test conditions and equipment are simple, and the effect of reducing test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

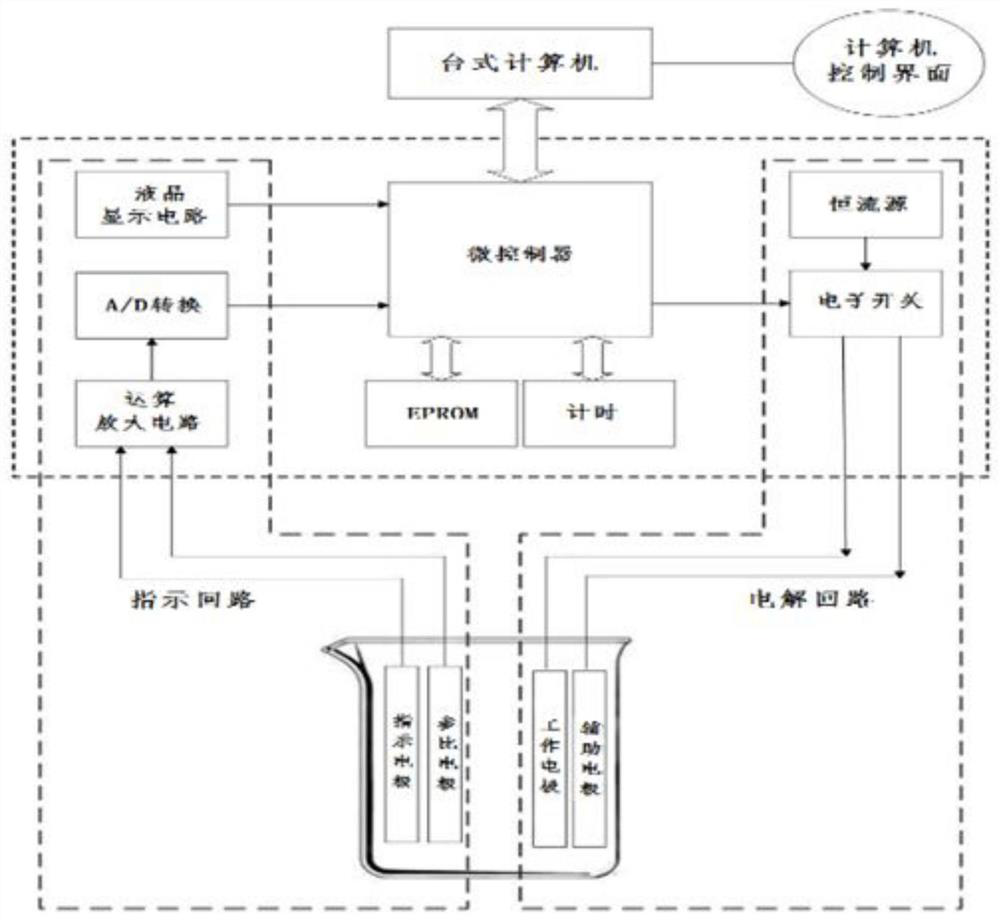

[0032] Analytical test object: LiPF numbered LIBE-01 6 electrolyte. use as figure 1 The device shown was tested for the LiPF 6 The free acid content in the electrolyte, the specific determination steps are as follows:

[0033] (1) Before the start of the experiment, turn on the electronic balance, pH meter and other electronic instruments to preheat for 30 minutes. During this period, assemble the acid-base coulometric titration digital endpoint instrument and ensure that its status is normal.

[0034] (2) Take an appropriate amount of LiPF to be tested from the glove box 6 The electrolyte solution was placed in a Teflon bottle with a stopper, and the bottle was quickly transferred to a beaker containing a mixture of ice and water for later use.

[0035] (3) Measure 50.00 mL of KCl aqueous solution with a concentration of 0.50 mol / L and place it in a polytetrafluoroethylene beaker, place the beaker in an ice-water bath placed on a magnetic stirrer, and work the pH composit...

Embodiment 2

[0042] Four LiPFs purchased from the market and numbered LIBE-02, LIBE-03, LIBE-04, LIBE-05 6 The electrolyte was used as the object, and the free acid content thereof was measured with reference to the method in Example 1, and the results are shown in Table 1.

[0043] Table 1LiPF 6 Determination results table of free acid content in electrolyte (n=5)

[0044]

Embodiment 3

[0046] Analytical test object: LiPF numbered LIBE-01 6 electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com