Ultra-rrequency of increasing resolution ratio in microdeposition controlling system

A technology of deposition system and deposition head, which is applied in the direction of processing and manufacturing, manufacturing tools, additive manufacturing, etc., and can solve problems such as expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT

[0060] The following description of preferred embodiments is merely exemplary in nature and is in no way intended to limit the invention, its application or uses. For purposes of clarity, the same reference numbers have been used in the drawings to identify similar elements.

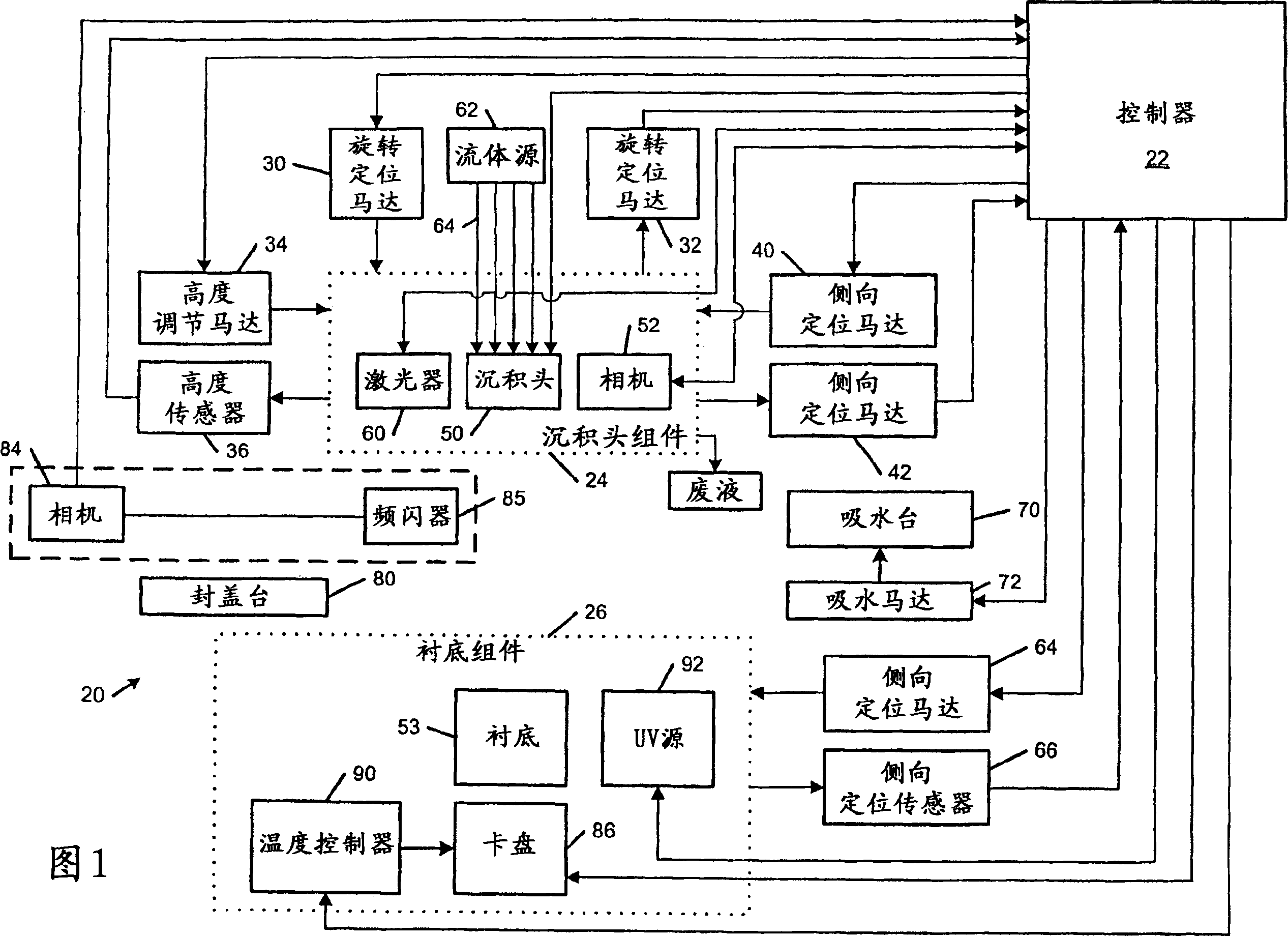

[0061] Referring now to FIG. 1 , there is shown a microdeposition system 20 including a controller 22 , a deposition head assembly 24 and a substrate assembly 26 . The rotational position or step of the deposition head assembly 24 is adjusted using a rotational position motor 30 and a rotational position sensor 32 . Similarly, the height of deposition head assembly 24 relative to substrate assembly 26 may be adjusted using height adjustment motor 34 and height sensor 36 . The lateral positioning of the deposition head assembly 24 is adjusted using a lateral positioning motor 40 and a lateral positioning sensor 42 .

[0062] On top of the deposi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com