Hot-pressing transfer printing method

A technology of heat transfer printing and pressure, applied in the direction of temperature recording method, etc., can solve the problems of escape, time waste, difficult quality control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

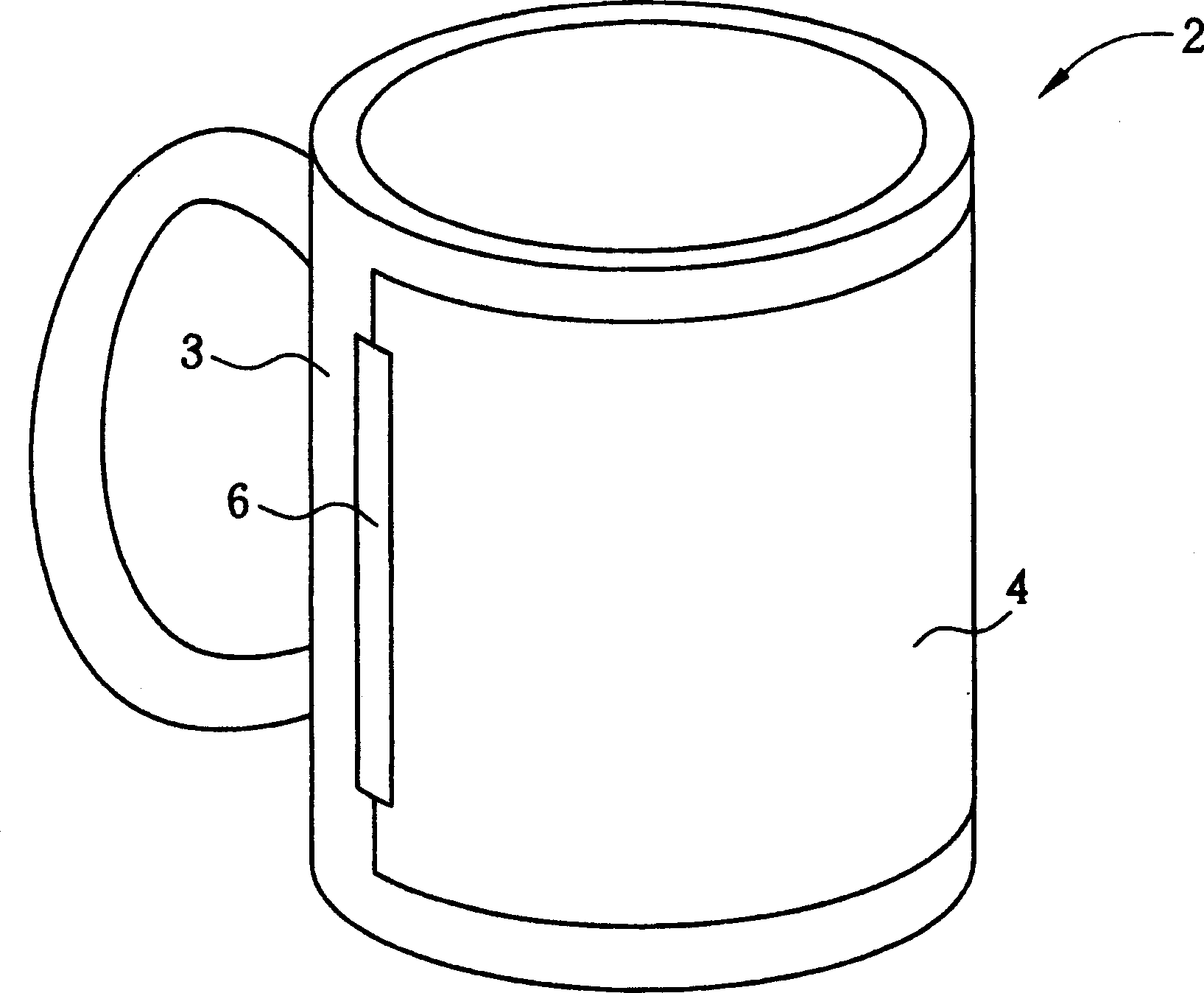

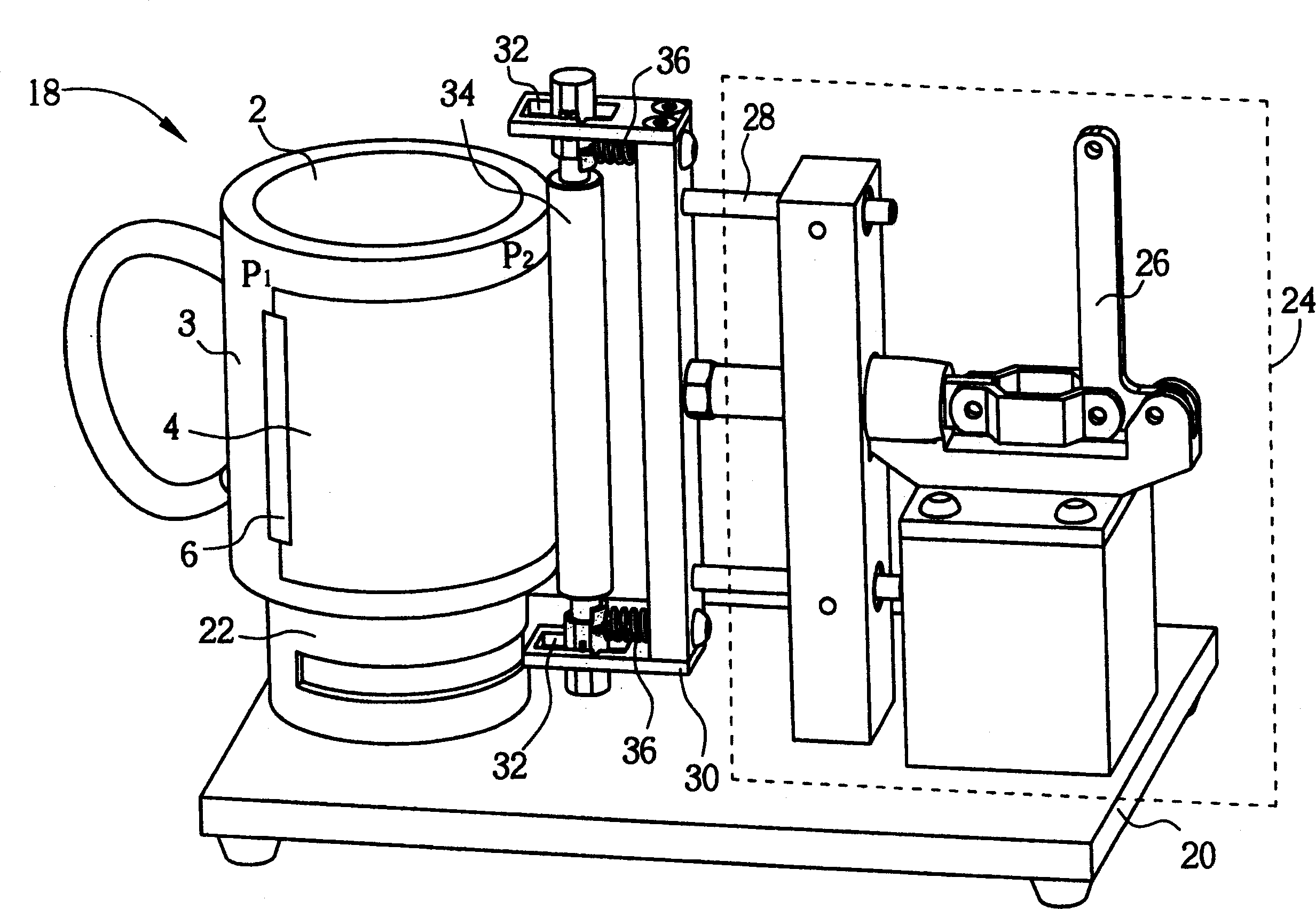

[0024] see figure 1 , figure 1 It is a schematic diagram of the bonding of a receiving transfer cup 2 and a photo paper 4 . Such as figure 1 As shown, the surface of the cup 2 is smoothed and usually coated with alkyd resin or melamine formaldehyde resin as a surface adhesive, and then the photo paper 4 is covered with a heat proof tape (heat proof) Adhesive type) 6 is flatly bonded to the cup surface 3 of the cup 2 .

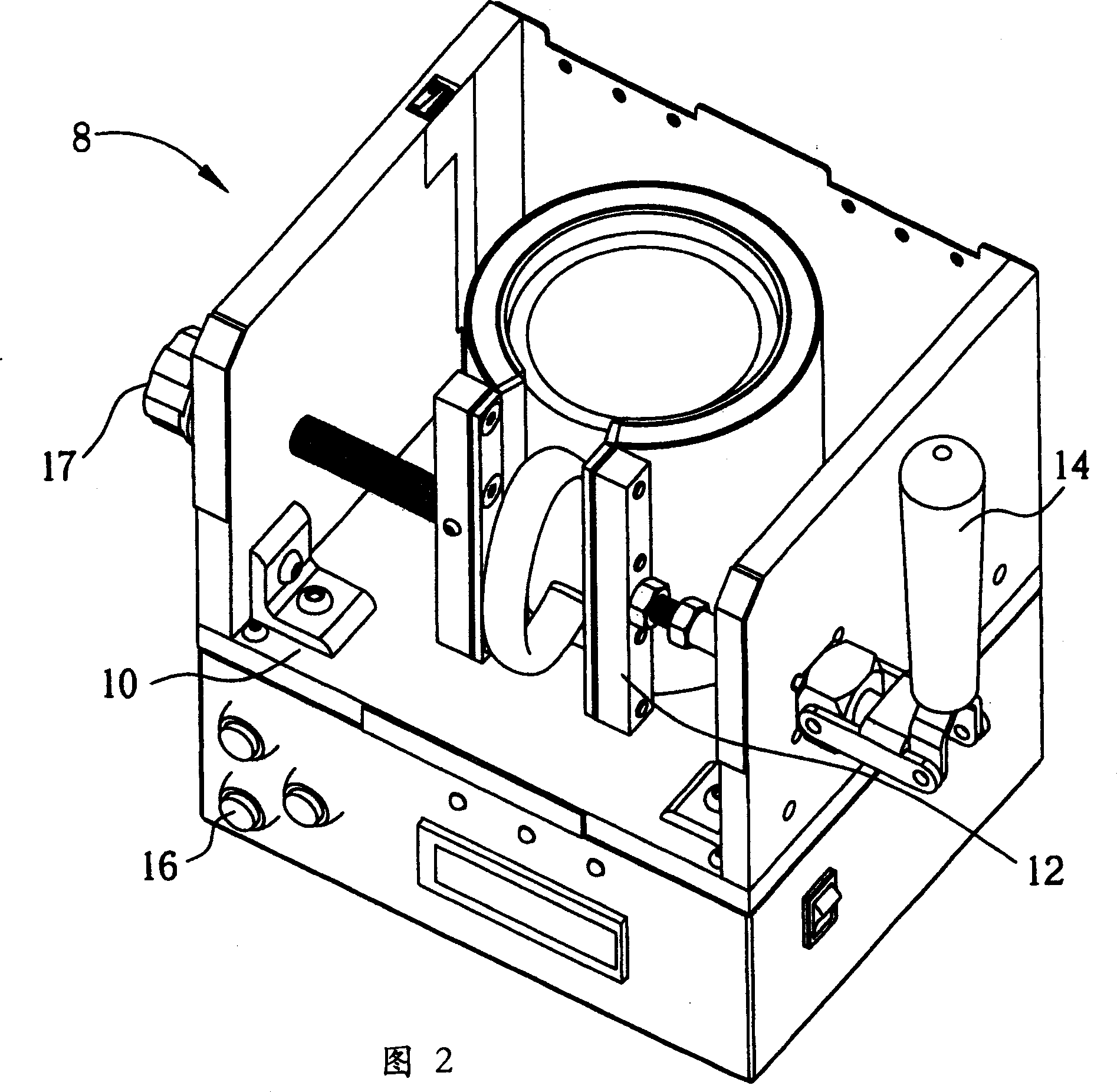

[0025] Please refer to FIG. 2 , which is a schematic diagram of the preheating device 8 of the present invention. The preheating device 8 is used to heat the photo paper 4 and the cup noodles 3. The preheating device 8 includes a preheating bearing seat 10, a fixing mechanism 12, and it includes a clamping rod 14 for the photo paper 4 and the cup noodles 3. Before the preheating process, an external force can be applied to the clamping rod 14 so that the fixing mechanism 12 clamps and fixes the cup 2 . The preheating device 8 further includes a temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com